▲ click the card above to pay attention to the “prefabricated building network” introduction with the in-depth development of vigorously promoting prefabricated buildings in China, the development and innovation of precast concrete technology and products has become a hot spot of architectural technology innovation in recent years.

Precast concrete components, as the basic components for the development of prefabricated buildings, have become the main products of building industrialization by assembling integral walls, plates, beams, columns, stairs and other supporting components.

In this case, there are various quality problems of precast concrete, which perplex the construction and use process.

In the whole concrete project, concrete maintenance is a sub project that takes the longest time and has the greatest impact on concrete quality.

The quality of concrete precast slab determines the service life of dressed buildings, which puts forward higher requirements for the maintenance of concrete precast slab.

The following is an example to talk about how the intelligent maintenance system combination scheme can meet the flexible production and maintenance needs of the prefabrication plant, and how to prevent and solve the problems and treatment measures in the production of precast concrete PC components.

Project overview Tianjin Hejia metal industry construction industrialization Co., Ltd Hejia metalworking (hereinafter referred to as Hejia metalworking) has a total investment of 360 million yuan in Ninghe industrial base, covering an area of 160 mu.

Hejia metalworking is committed to promoting the industrialization of prefabricated buildings and the industrialization of prefabricated buildings.

The products of construction industrialization mainly include: Prefabricated laminated plates, prefabricated stairs, exterior wall plates, interior wall plates, partition walls, balconies, etc.

there are two production lines of prefabricated components in Hebei Xindadi, one is laminated Plywood production line is a comprehensive production line.

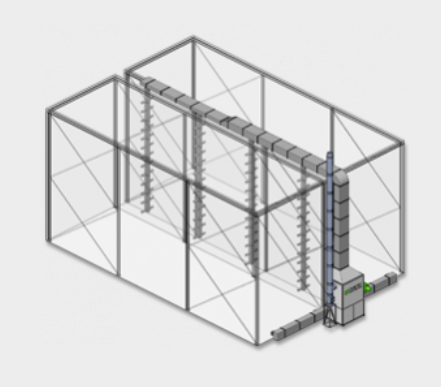

Each production line has 2 face-to-face warm air curing kilns, a total of 4 curing kilns and more than 140 fixed formwork.

If the production scale of concrete precast slab is large and the traditional steam boiler maintenance is adopted, the maintenance cost and later maintenance cost will be a great expense; Secondly, the boiler is a special equipment, which needs to be declared for annual inspection, and the boiler room also needs to be built.

If the boiler room is far from the workshop producing concrete precast slab, some heat will be lost during steam transmission, resulting in energy waste, and the equipment utilization rate is not high due to the limitation of existing space and power distribution; Finally, in the production process, if the operator cannot accurately control the curing temperature, humidity and temperature rise / drop rate of the concrete precast slab, the quality of the product is difficult to be guaranteed.

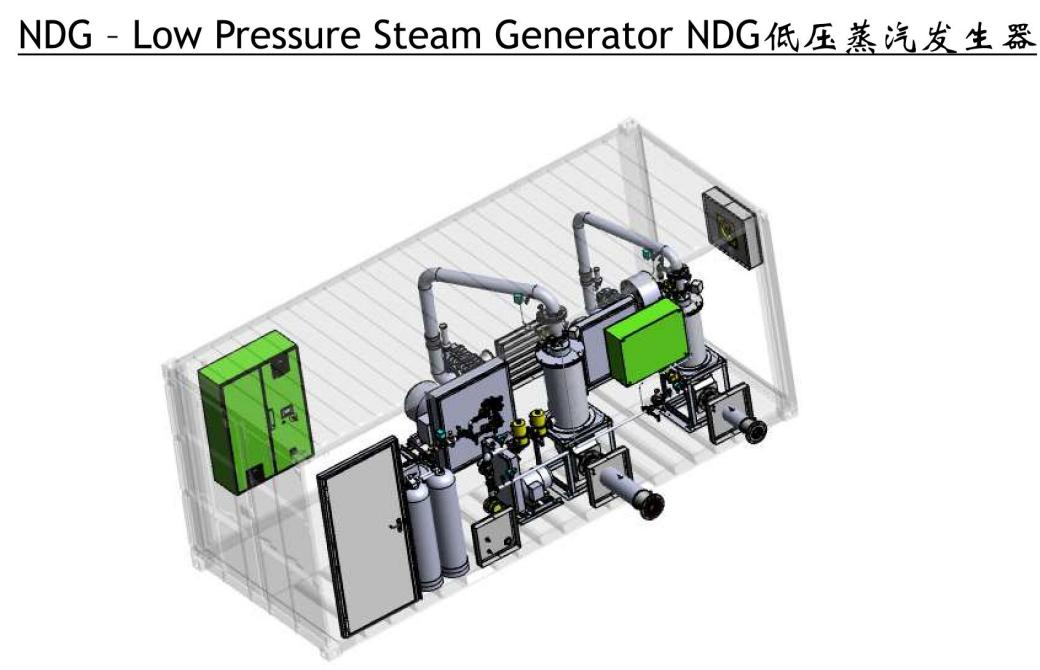

Therefore, by introducing the flexible combined curing scheme of German curtec gulte CONCURE warm air heating curing kiln system equipment + NDG low-pressure steam generator with advanced technology in the concrete curing industry, the engineering purpose is achieved, the quality problems such as cracks in the production process of components are controlled, and the strength of concrete components is improved, It can flexibly adapt to the needs of intermittent maintenance and continuous maintenance, so as to save energy consumption cost and accelerate the construction period.

Fig.

1 specific maintenance scheme and principle engineering scheme of Hejia metal factory project 1 – warm air heating maintenance of four prefabricated PC component maintenance Kilns: customized German curtec gulte CONCURE warm air equipment we250b Fig.

2concure warm air heating system maintenance kiln design Fig.

3 prefabricated component warm air maintenance kiln (field installation drawing) the main content of the equipment includes the heating heater device – warm air generator, which works at 250KW / h.

The warm air generator used is a forced circulation vertical air pipe heat exchanger, which can quickly and effectively separate high-quality hot air.

This is the basic configuration of the warm air system.

The curetecconcure warm air heater is set for heating and circulating maintenance room Air in the.

The indoor air is sucked in through the return pipe, heated in the warm air furnace, and transmitted back again through the circulation pipe and the branch pipe of the room.

Different levels of air circulation and air distribution ensure that the temperature distribution in the whole room is very uniform.

Heating medium can be oil, gas, hot water, steam, electric energy or solar energy.

CONCURE heating system can also provide a variety of performance specifications, ranging from 40kW / h to 1200kW / h.

All CONCURE heating systems are designed according to customer needs, For piping system (design, material) and heaters of different sizes are arranged differently to provide the highest efficiency and performance.

The standard pipe structure is a standard galvanized air duct with thermal insulation material.

All CONCURE heating systems have the advantages of long service life, low maintenance cost and economic operation.

The structure of the heating generator is shown below.

Fig.

4 , structural diagram of the heating generator , Figure 1 The main body of the air generator is connected in series with the heat exchanger through the upper part, and the lower part is connected in series with the fan.

The whole heat exchanger is made of stainless steel.

Figure 5.

Warm air heating system – Physical diagram of generator.

Curing principle of warm air curing kiln: concrete needs heat and moisture to hydrate perfectly.

The cement mix proportion of precast concrete components already contains a lot of water, so we only need to add heat to the curing process.

Through CONCURE, a system is designed to heat and circulate the air in the kiln without increasing moisture.

Due to the high moisture content, we only need to ensure that the temperature and circulation are correct.

The warm air enters from the higher pipe of the curing kiln, and the air is heated by the air burner and evenly rises to different heights of the room through the CONCURE warm air heating system.

In addition, the curing process of concrete products is an exothermic process, and the released heat can also ensure that the temperature in the kiln does not decrease, which can reduce the supplement of internal and external heat sources of the whole curing system, so it can save operating energy.

The humidity contained in the wet pouring component itself is stable without loss in the sealed kiln, so as to maintain the constant temperature and humidity in the curing kiln and realize ecological maintenance.

Fig.

6 , two parallel curing kilns with warm air curing system (as built drawing) , Fig.

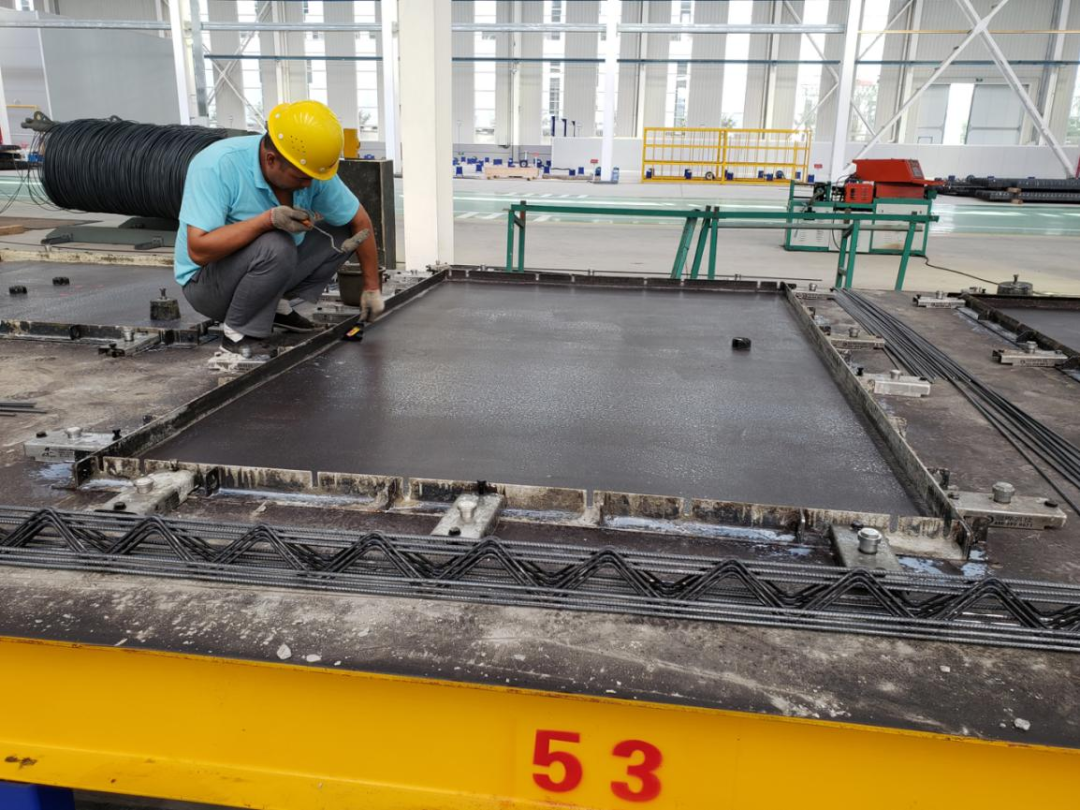

7 , warm air curing kiln and assembly line production mold table Fig.

8 , assembly line mold table prefabricated laminated plate (in production) Figure 9: demoulding of on-site prefabricated laminated plate – satisfactory effect of curing finished products.

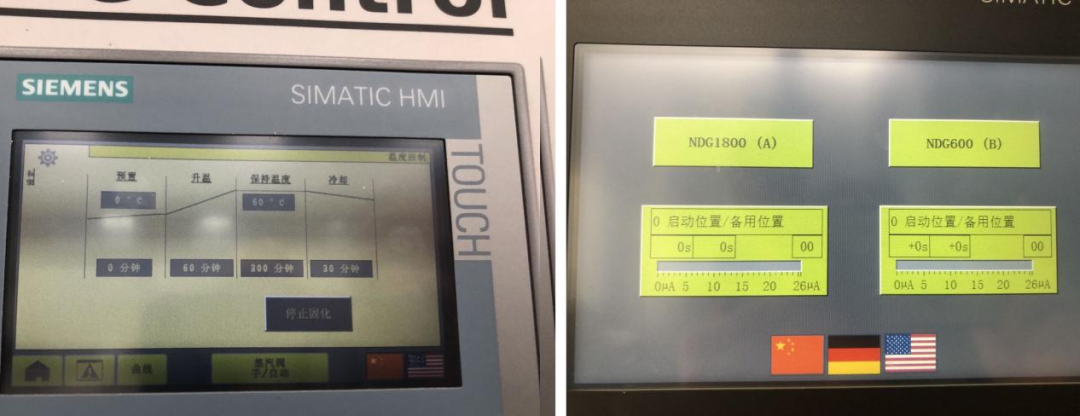

Functions and advantages of gulte CONCURE heating system combined with flow production: ★ saving space and ensuring rapid curing of concrete prefabricated components and saving curing time ★ saving space when storing concrete prefabricated components and curing under the best environmental conditions ★ continuous monitoring and automatic maintenance Adjust the internal temperature in the heat preservation and curing kiln to ensure the best curing of concrete prefabricated components, and automatic constant temperature curing can effectively reduce the probability of cracks ★ the temperature in all corners of the curing kiln is consistent without temperature difference ★ there is no corrosion of condensate to the curing kiln, so as to prolong the service life of the curing kiln ★ support assembly line and automatic line production, High efficiency and energy saving ★ the temperature is not affected by the external environment ★ the heating circulation system has automatic control and monitoring, intelligent system, multi language switching and fool operation, so as to ensure the ideal curing process of concrete precast components.

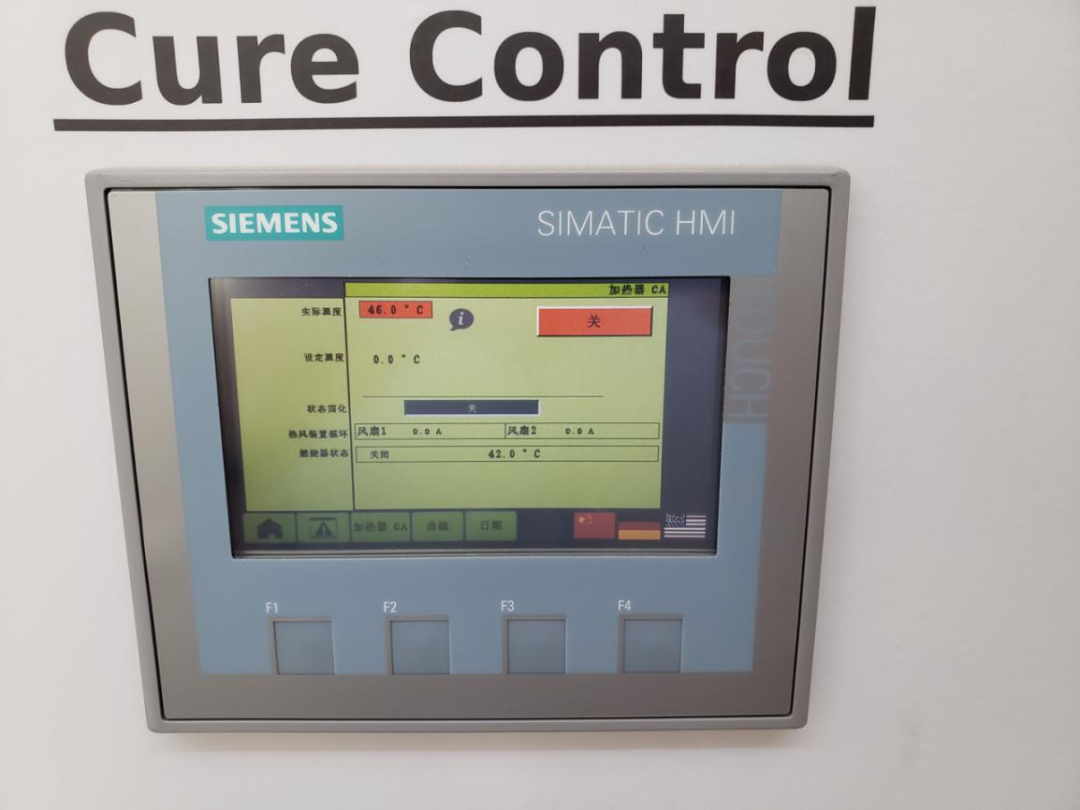

Figure 10: German Siemens intelligent system controller and display screen – any switching between Chinese, German and English.

The warm air heating maintenance system is one of the best choices for the maintenance of PC component assembly line and automatic production line.

The maintenance system has become the preferred scheme for the maintenance of prefabricated components in Germany and other European and American countries due to its advanced equipment and mature energy-saving and environmental protection technology.

Compared with the popular steam curing system in China, the warm air curing kiln system is still in the introduction period of foreign new technology products and equipment in China.

Component factories need to try and find the most suitable curing scheme in combination with their own production conditions and curing products..