Click “steel structure design” above to pay attention to my source: prefabricated building network (ID: yuzhijianzhuwang); Author: Li Weixing.

Source: Tianhua building industrialization technology center, 01 steel structure system and development status, current domestic policy background, working meeting of the Ministry of housing and urban rural development on December 24, 2018.

In January 2019, the notice on printing and distributing the key points of work of the construction market supervision department of the Ministry of housing and urban rural development in 2019 was issued: “vigorously develop prefabricated buildings such as steel structures, actively resolve the imbalance between supply and demand of building materials and labor, and accelerate the improvement of prefabricated building technology and standard system.” The Ministry of housing and urban rural development has successively carried out pilot construction of steel structure prefabricated houses in Shandong, Hunan, Henan, Sichuan, Jiangxi, Zhejiang and Qinghai, It will last for three years (2019-2022).

On October 29, 2019, the notice of the national development and Reform Commission on printing and distributing the overall plan for green life creation action (fghz [2019] No.

1696): “(V) promote the fabricated construction mode.

Vigorously develop fabricated buildings such as steel structure, and adopt steel structure in principle for new public buildings.” On August 28, 2020, The Ministry of housing and urban rural development and other 9 departments jointly issued several opinions of the Ministry of housing and urban rural development and other departments on accelerating the industrialization of new buildings (jbg [2020] No.

8):“ (10) We will vigorously develop steel structure buildings.

We will encourage hospitals, schools and other public buildings to give priority to the use of steel structures, and actively promote the construction of steel structure residential and rural houses.

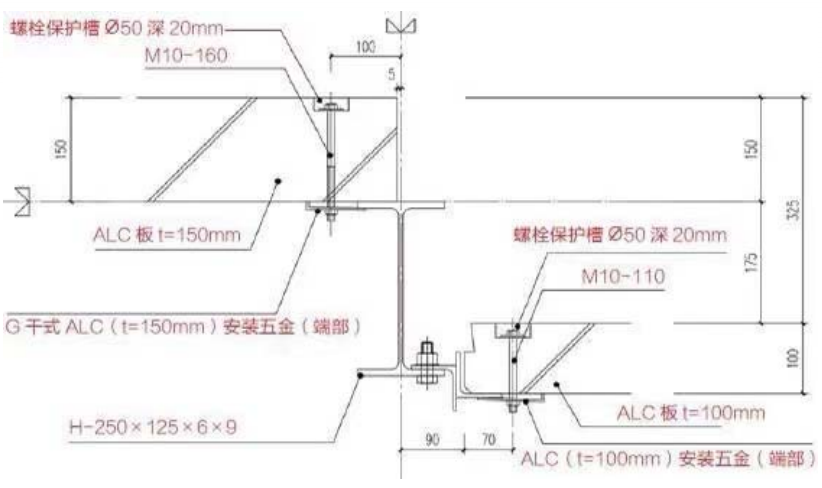

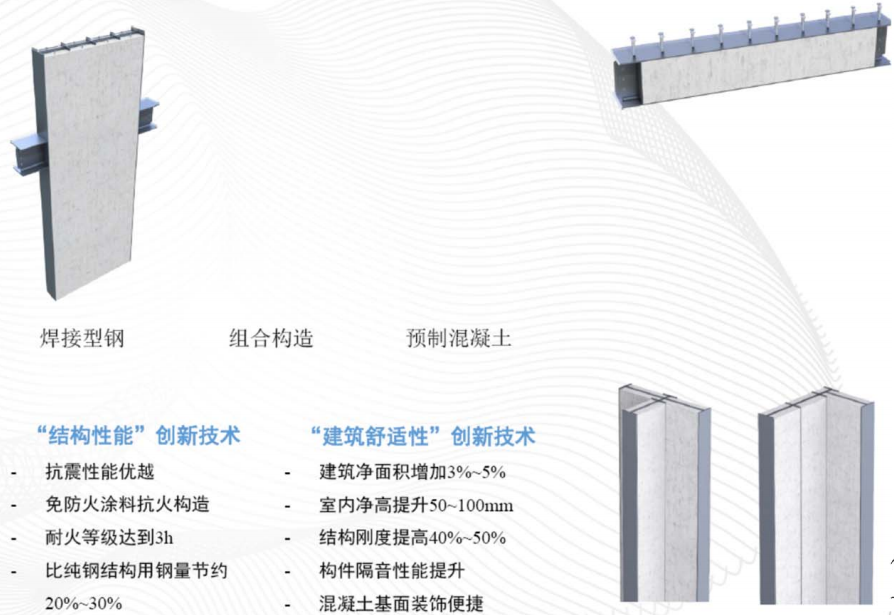

We will improve the performance and technical measures for fire prevention and corrosion prevention of steel structure buildings, increase the application of hot-rolled H-section steel, weather resistant steel and fire-resistant steel, and promote the all-round development of key technologies of steel structure buildings and related industries.

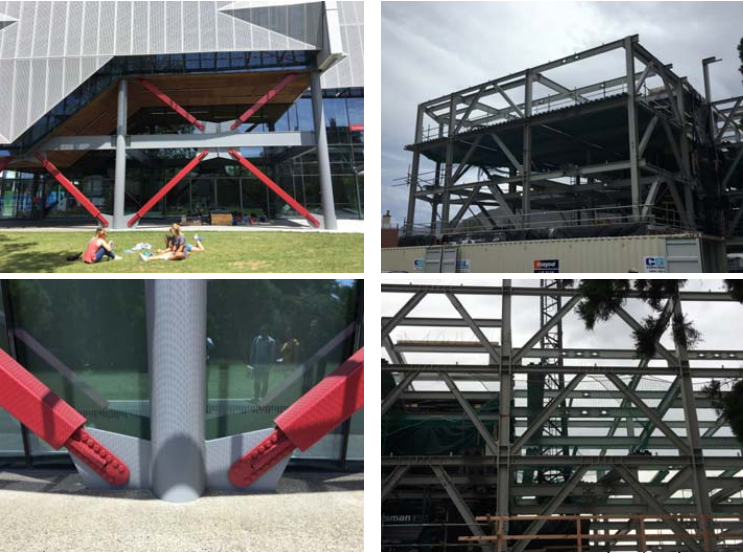

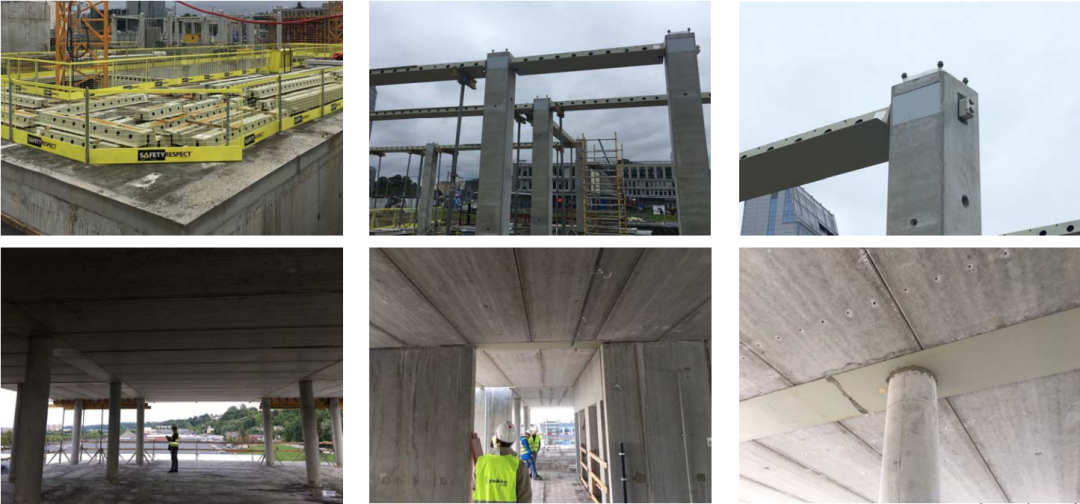

“Foreign building structures Development trend of the system – Take New Zealand as an example.

Due to the strong structural seismic fortification measures in New Zealand, few houses collapsed in the Christchurch earthquake in 2011.

Although a large number of buildings did not collapse, they were seriously damaged and had no repair value.

As a result, 70% of the buildings in the central business district (CBD) of Christchurch had to be demolished and rebuilt.

Although none of the 51 tallest buildings in Christchurch collapsed, 37 buildings were forced to be demolished after the earthquake.

The Christchurch earthquake fully reflects the important value of structural seismic “resilience”.

Post earthquake recoverability has become the focus of engineering research, Almost all buildings in Christchurch CBD and Addington are made of reinforced concrete (RC) frame or shear wall is used as their structural system.

However, during the reconstruction of Christchurch since 2011, the approximate proportion of the number of buildings with steel structure, RC structure and wood structure for the horizontal lateral force resistance system is 10:10:1.

The RC bending frame as the horizontal lateral force resistance system that can be seen everywhere before the earthquake is basically no longer used in the reconstructed CBD, and the reconstructed concrete structure is few Almost all of them use shear wall structural systems.

Although there are no mandatory provisions requiring the use of more resilient structural systems in reconstruction, many engineers will still make the storey displacement under the design level earthquake far less than the maximum limit in the code when designing buildings, The purpose is to limit the post earthquake damage of structural and non structural members.

More and more people begin to accept the concept that preventing life loss as the goal of seismic performance is indeed not enough for an excellent modern structure.

Data source: Rebuilding Christchurch: the transformation of seismic design of building structural system, written by Michel Bruneau, Greg MacRae, Wang Wei The earthquake in New Zealand has brought great changes to the building structure system.

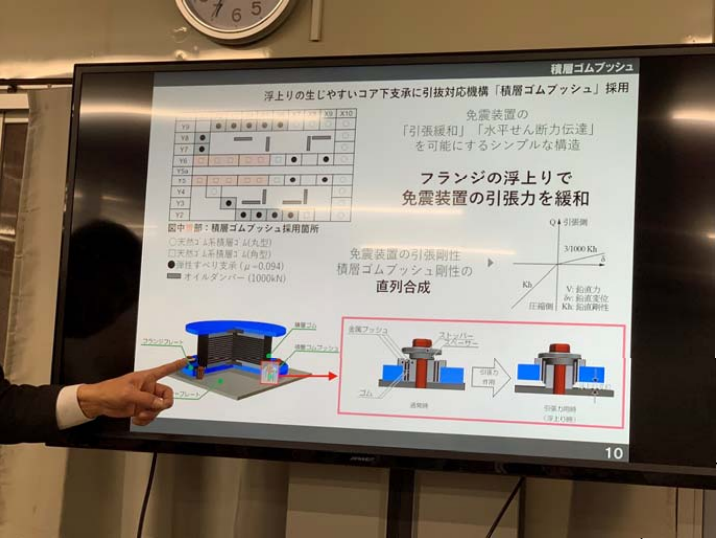

The most frequently used systems of new steel structure buildings in New Zealand are: buckling restrained brace (BRB) frame, traditional flexural frame (MRF), flexural frame with beam end section weakening (RBS dog bone), eccentric braced frame with replaceable energy dissipation beam section (EBFs), and central braced frame (CBFS), conventional eccentrically braced frame, swing steel frame system, etc..