The following points should be paid attention to in the preliminary design stage of prefabricated buildings.

the outer wall should be flat.

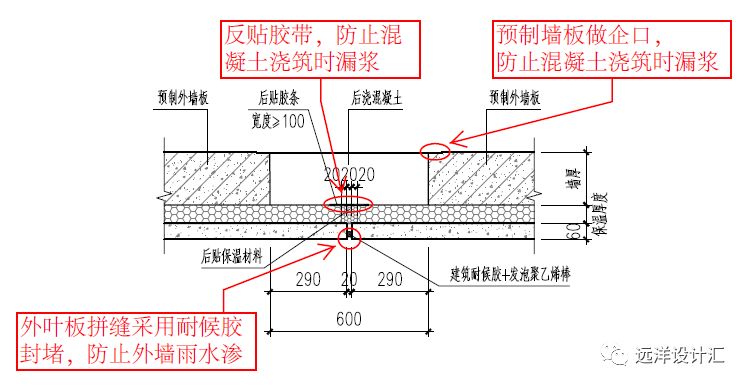

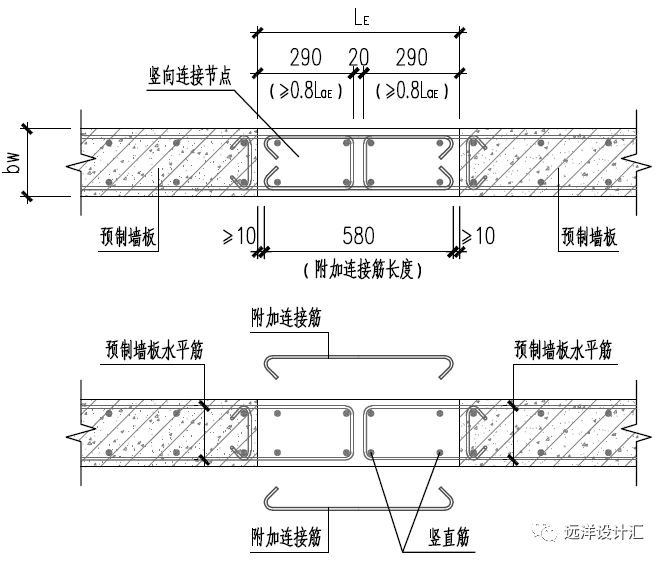

Typical connection node details of precast members.

The plane shape of the structure should be simple and regular, and the distribution of mass, stiffness and bearing capacity should be uniform.

For the applicable height of the structure, the maximum service height of the house with assembled integral shear wall structure is lower than that of cast-in-situ shear wall structure to a certain extent.

Collaborative design of various disciplines.

The standard has made clear evaluation methods and bottom line requirements for prefabricated buildings.

Disassembly of prefabricated components.

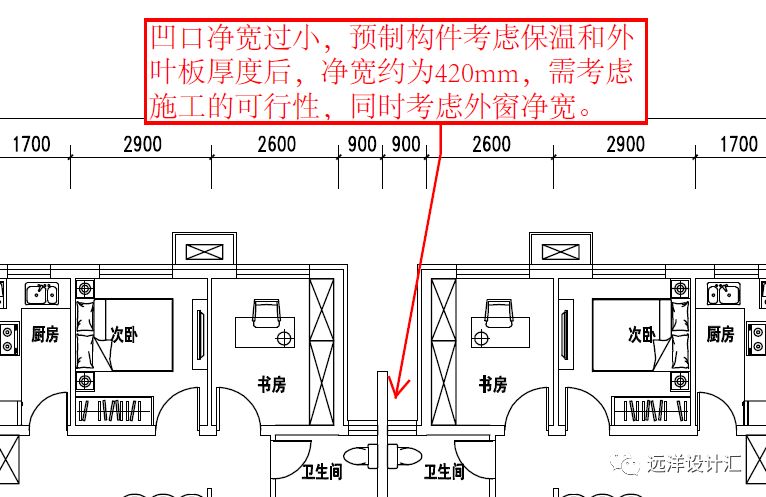

B , the clear width of the plane notch is too small.

Table 2.1 key contents of prefabricated component splitting 4 Contents of preliminary design drawings of structure discipline: A.

5.

5.

71 document “guidance of the general office of the State Council on vigorously developing prefabricated buildings” in 2016, the transformation of the traditional construction industry has been irreversible, and the prefabricated buildings will become an important way to build the construction industry in the future.

The lateral stiffness of the structure should be large from bottom to top and change evenly gradually.

See Annex 2.1 for the common forms of prefabricated wallboards.

1、 Compared with the traditional cast-in-situ shear wall structure, the prefabricated shear wall structure has two remarkable characteristics: first, the cost increment is large, (when prefabricated components are used, the weighted comprehensive unit price of various types of reinforced concrete components is about 3 times that of cast-in-situ components); secondly, the feasibility of adopting prefabricated components should be considered in the layout of structural walls.

The section thickness of prefabricated wallboard shall not be less than 200mm.

Focus on the following points: A.

The splicing parts on both sides of the wallboard should be set at the parts with less structural stress; The vertical prefabricated components shall be of I-shape first, and three-dimensional components such as L-shape, T-shape and U-shape shall not be used.

b.

6.

The specific regularity should be judged in accordance with the code for seismic design of buildings GB50011.

Therefore, the structural discipline needs to intervene in advance in the architectural scheme design stage of the project constructed by assembly, so as to analyze the feasibility and economy when the architectural scheme adopts assembly, so as to avoid post construction The modification of phase I scheme affects the development progress of the project.

The following points should be paid attention to in the scheme design stage of fabricated shear wall structure.

Structural plan, including structural plan of each floor and roof structure plan; The number of prefabricated components shall be indicated, and the corresponding relationship between the number and model of prefabricated components shall be given, including the weight of components, etc.

Meet the requirements of subsequent construction operation.

For the structure with transfer layer, the frame support layer and the adjacent upper layer shall adopt cast-in-situ structure.

See Table 1.1 for the specific comparison.

c.

The vertical shape of the structure should be regular and uniform to avoid excessive overhang and retraction.

After entering 2018, The rating standard for prefabricated buildings (GB / t51129-2017), another important document of prefabricated buildings, has been issued and implemented.

Information design (BIM)..

floating windows should not be used to avoid three-dimensional prefabricated components as far as possible.

The form of prefabricated components should be concise to help control the cost.

According to the technical points of different disciplines, analyze the factors affecting construction cost, construction progress and construction quality, adopt scientific and effective technical combination, do a good job in collaborative design and control the assembly rate.

According to the requirements of the standard, “only horizontal prefabricated components and no vertical prefabricated components can be called prefabricated buildings” , which has the greatest impact on the current prefabricated buildings.

3.

1.

See example figures a and B.

Serious irregular plane layout should not be adopted.

Source: Ocean Design Collection Author: Yang Suozhu, please contact and delete if there is infringement.

The building adopts modular design, Basic modulus 100mm (1M=100mm) the first mock exam should be 2M, 3M, 6M, 9M…

The content of the report document is basically consistent with the depth of the preliminary design, so doing a good job in the preliminary design can effectively improve the design cycle of subsequent construction drawings.

Introduction after the issuance and implementation of the State Council No.

See Table 2.1 for how to realize the scientific separation of prefabricated components.

The following points are mainly concerned: whether the A.

b.

Figure 2.1 common forms of prefabricated wallboard the core of building industrialization is production industrialization, and the key to production industrialization is design standardization.

Determine the number of cast-in-situ floors at the bottom of the building.

B.

According to the relevant provisions in the technical specification for prefabricated concrete structures: a.

structural design description, including special articles on fabricated design.

3.

The project should adopt unified modulus, modular unity can reduce the types of prefabricated components, and effectively reduce the construction cost.

Structural discipline calculation sheet, Including calculation of prefabrication rate (volume rate) of vertical components, calculation of prefabrication rate (area rate) of horizontal components, etc.

The key point to realize standardization is reflected in the scientific separation of prefabricated components; Therefore, the scientific splitting of prefabricated components is the core work of prefabricated building structure design.

1.

II.

A , B the outer wall is uneven.

Taking the most common shear wall structure as an example, this paper summarizes the key work of structural design at each stage in the process of prefabricated building design with prefabricated vertical members.

4., the feasibility of precast components is adopted.

The scientific splitting of prefabricated components will have an impact on the building function, building plane and facade, structural stress, bearing capacity of prefabricated components, project cost and so on.

the shear wall at the reinforced part at the bottom of high-rise shear wall structure should adopt cast-in-place concrete.

The preliminary design of prefabricated building structure is required for all projects constructed by assembly according to policy requirements Special report on industrialization implementation plan.

d.

Table 1.1 maximum height applicable to different types of shear wall structures (m) 2.

2.

corner wall and the length of the window wall meet the assembly implementation.

In the past few years, prefabricated horizontal members have been widely used in prefabricated buildings, and the technology has been relatively mature; The prefabricated buildings with prefabricated vertical components are less used, and the engineering experience is relatively lack.

A-1 the length of corner wall is too small (corner window) A-2 the length of the wall between windows is too small.