(click the picture to view the registration details) source: Rong Lijuan 1, he Xinhui 1 (the Fourth Construction Co., Ltd.

of China Construction Seventh Bureau 1, Xi’an 710000) [Abstract] with the development and growth of assembly, component production enterprises are also gradually increasing.

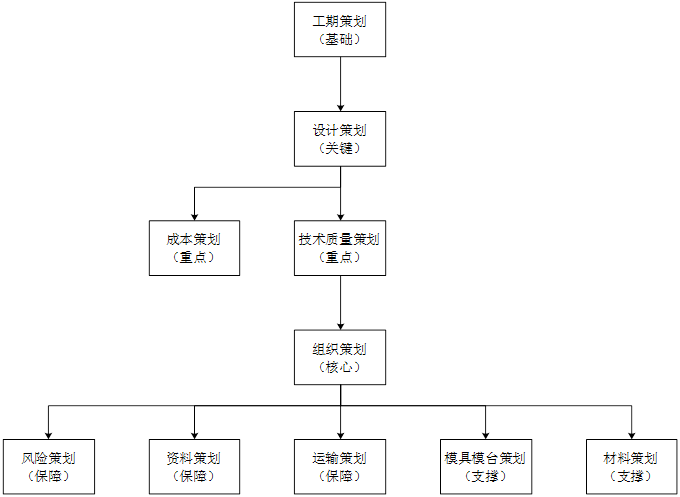

In order to complete the orders of prefabricated components with quality and quantity, this paper expounds the key points and process analysis of prefabricated component production organization planning in many aspects, including construction period planning, design planning, cost planning, technical quality planning and organization planning , material planning, mold platform planning, data planning, transportation planning and risk planning provide reference for prefabricated component manufacturers Keywords assembled; prefabricated component; Key points of production organization planning for prefabricated components and process analysis Rong Li Juan 1, hexinhui # 1 (China Construction Seventh Engineering Division.

Corp.

Ltd, Xi’an 710000) Abstract: with the development of assembly type, the number of component manufacturing enterprises increasing Inordertocompletetheordersofprefabricatedcomponentswithqualityandquantity,thispaperexpoundsthekeypointsofproductionorganizationplanningofprefabricatedcomponentsfromvariousaspects,includingconstructionperiodplanning,designplanning,costplanning,technicalqualityplanning,organizationplanning,materialplanning,moldplatformplanning,dataplanning, transportationplanningandriskplanning,whichprovidesreferenceforthefutureItcanbeusedforreferencebythemanufacturersofprefabricatedcomponentsKeywords:prefabricated; prefabricatedcomponent; Plan 0 Introduction unlike the traditional construction project department, prefabricated component manufacturers generally face prefabricated component orders of multiple projects at the same time.

In order to ensure quality and quantity supply, they need to carry out production organization planning for component orders.

Due to different operation modes, component manufacturers have different responsibilities in prefabricated structure engineering, However, most enterprises should undertake the responsibilities of drawing review, technical disclosure, production organization and factory acceptance.

Based on the implementation experience of multiple component order projects undertaken by enterprises, this paper expounds the key points and brief process of prefabricated component production organization planning in multiple directions, so as to lay a foundation for prefabricated component production enterprises to prepare production organization design.

1.

Key points of planning the stage described in this paper starts from the signing of the contract for prefabricated components to the end of the mobilization acceptance of components.

Figure , analysis of production organization planning process of prefabricated components , 1.1 construction period planning after signing the prefabricated component contract, the component production enterprise first communicates with the installation and construction unit to determine the number of buildings, component types, construction schedule of each building and installation time of the first floor.

According to the safety time of the first floor, determine the drawing design period, mold manufacturing period, material procurement period and component production period.

The length of the period involves the allocation of materials and personnel of the component production enterprise.

Determining the period is the basis of component production planning.

1.2 design planning and design standardization is the prerequisite for component standardization, mold standardization, production standardization and easy quality control.

The current industrialized production team is not mature enough.

On the premise of ensuring the assembly rate, the disassembly of prefabricated components should be based on the design principle of simplification and standardization, and the weight and size of components should be considered to meet the requirements of hoisting and transportation.

According to experience, some personnel of the design unit have insufficient experience in assembly construction and disassembly, resulting in multiple changes in the later stage.

The prefabricated components that have been produced can even be scrapped, resulting in a waste of resources.

Therefore, the accuracy of disassembly design is very important.

In the early stage, the component manufacturer shall communicate with the designer on the splitting standards.

Design standardization and accuracy are the key to component production planning.

1.3 cost planning can enter the cost planning stage after signing the prefabricated component contract and splitting the drawings, mainly including ① materials.

If it is not agreed in the contract, for the materials with high price of the specified brand, communicate and negotiate with the construction unit and the design unit, and try to use the materials whose quality meets the requirements of the component manufacturer, which shall be confirmed by written agreement or design change; For imported materials with high unit price, try to replace them with domestic materials that meet the specification requirements, issue quality inspection certificate and obtain the approval of the construction unit, design unit and supervision unit; ② Design standardization and accuracy are the key to reducing cost and increasing efficiency; ③ According to the drawings, the construction drawing budget is calculated according to the labor quota of the component production enterprise, the construction cost is calculated after the completion of the project order, the two are compared and analyzed, the causes are found, specific countermeasures are formulated, experience is summarized and enterprise standards are formulated; ④ It should be noted that the cost planning should consider the cost of measures and materials, such as lifting point stiffeners of laminated plates, auxiliary lifting nails for internal and external wall lifting, etc., which should be added to the construction drawing budget.

Cost is the focus of production organization planning of prefabricated components.

1.4 technical quality planning (1) Drawing review.

After the split drawings of prefabricated components are determined, the technical quality shall first review the drawings.

The key points of drawing review mainly include: whether the name and number of prefabricated components are clear and unique; whether the material and dimension information of embedded parts are complete and clear; whether the number of prefabricated components is clear; whether the position and quantity of lifting points and inclined supports are reasonable; whether the reinforcement interferes with the embedded parts; and whether the reinforcement is reinforced Whether the reinforcement number in the drawing is complete; Whether the truss height can meet the processing requirements.

According to experience, the existing domestic equipment can only process trusses with a height of more than 70mm.

For trusses with a height of less than 70mm required by special plate thickness, it is necessary to butt joint and change with the Design Institute in advance.

It should be noted that confirm whether the component split diagram of the top layer is consistent with the standard layer.

(2) Material statistics.

After the component splitting drawing is issued, the drawing materials shall be counted, including the quantity of different types of components, statistics of main materials and auxiliary materials.

The main materials are the direct materials that make up the components, such as concrete, reinforcement, lifting point, inclined support embedded parts and hydropower embedded parts; the auxiliary materials are the materials that do not directly form the prefabricated components, such as release agent Sealant, washing agent, etc..