The official account of the assembled building practitioners should have received many messages from fans of the network recently.

Many of them are PC component factories.

Today, we have devoted some time to the problems encountered by the component factories.

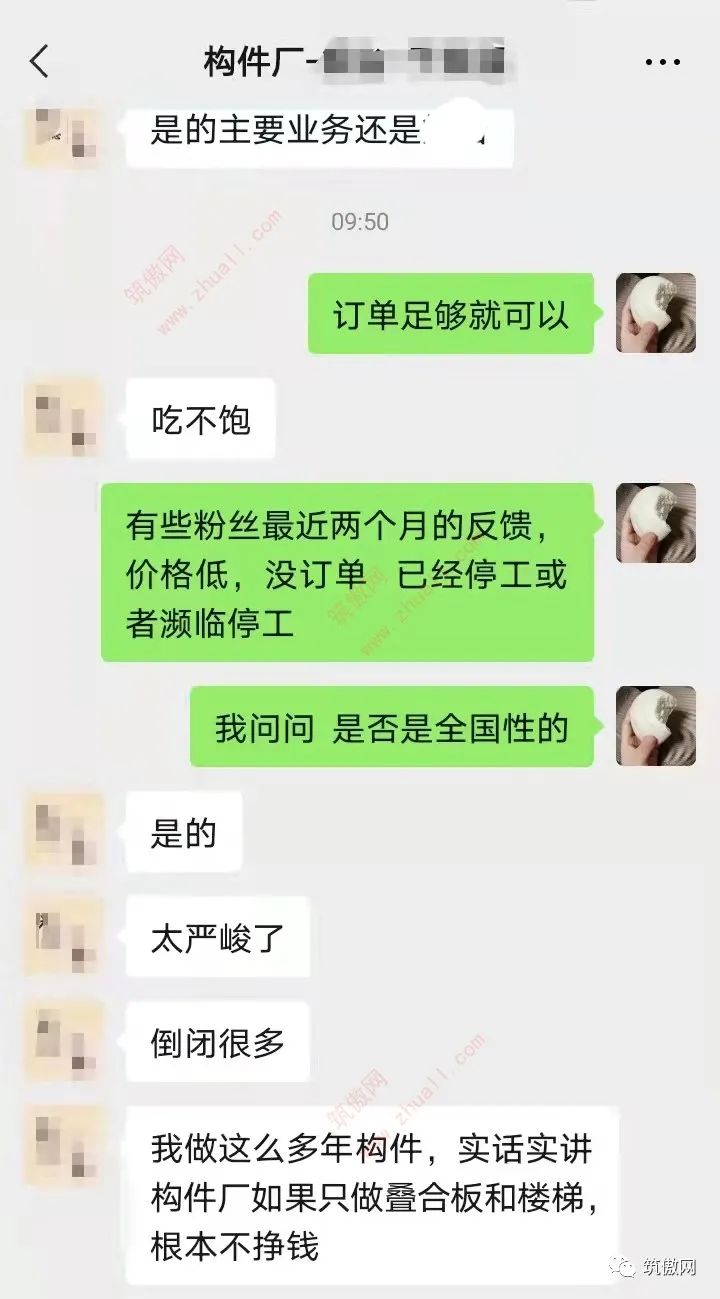

I also consulted the heads of several PC component factories (protect privacy, especially hide the name), summarize the difficulties encountered in the concentration of prefabricated component factories in four points.

What problems have other component factories encountered? Please leave a message in the comment area: I.

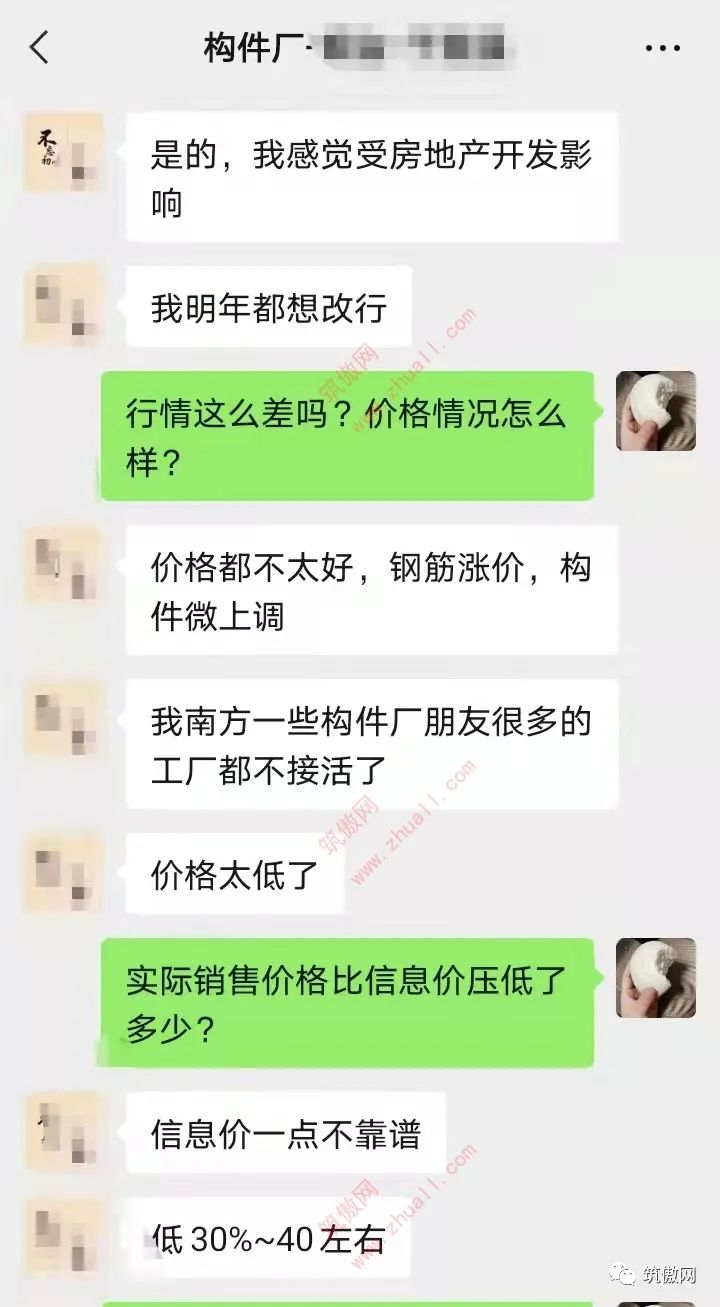

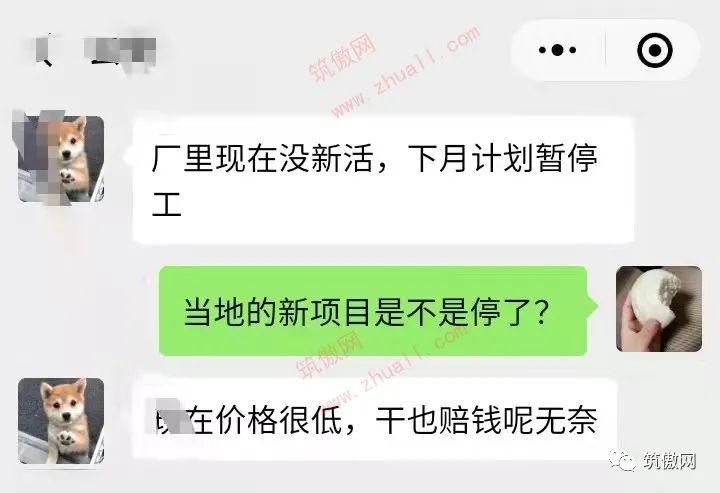

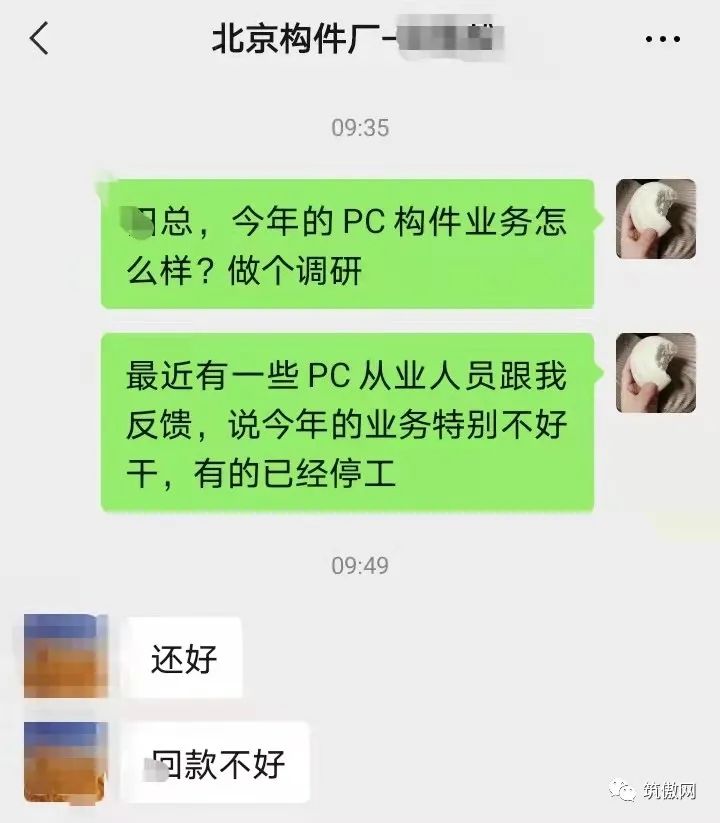

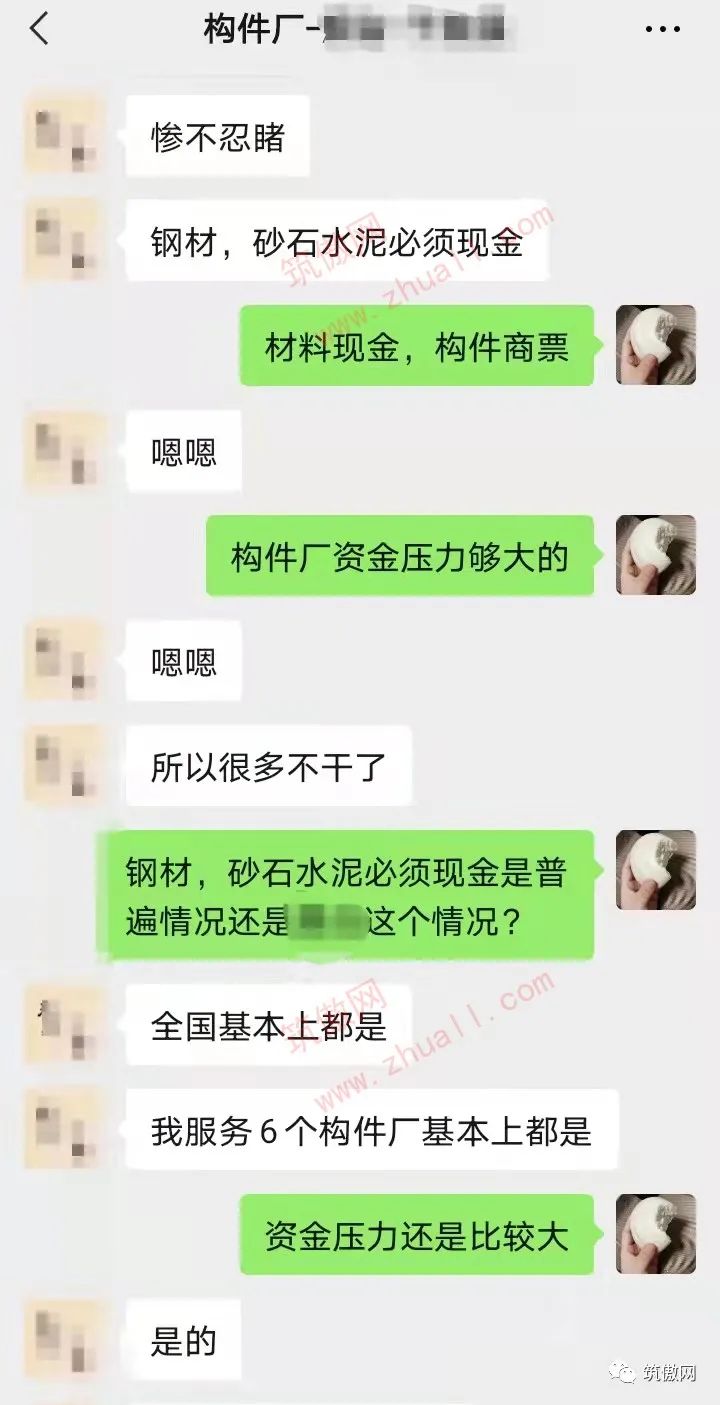

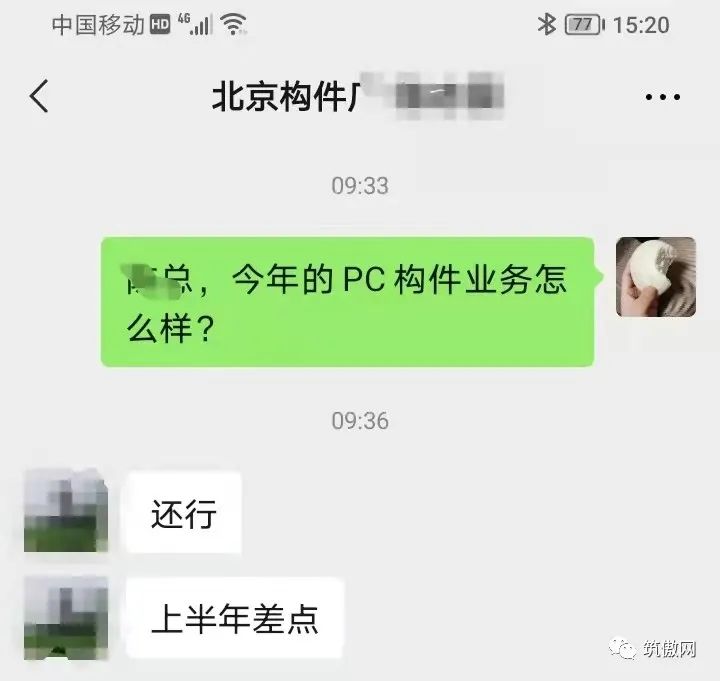

about the operation of PC component factory ▲ PC component factory has insufficient orders and operating difficulties ▲ PC component factory needs cash payment for materials, but the components receive commercial acceptance ▲ PC component manufacturer Business acceptance delay ▲ PC component factory has insufficient component orders and some components have no profit ▲ the actual sales price of components in PC component factory is low ▲ a PC component factory in Beijing is OK, almost in the first half of 2021 ▲ a PC component factory in Beijing is OK, and it is difficult to collect payment.

Comprehensive: the current business situation of component factories: 1.

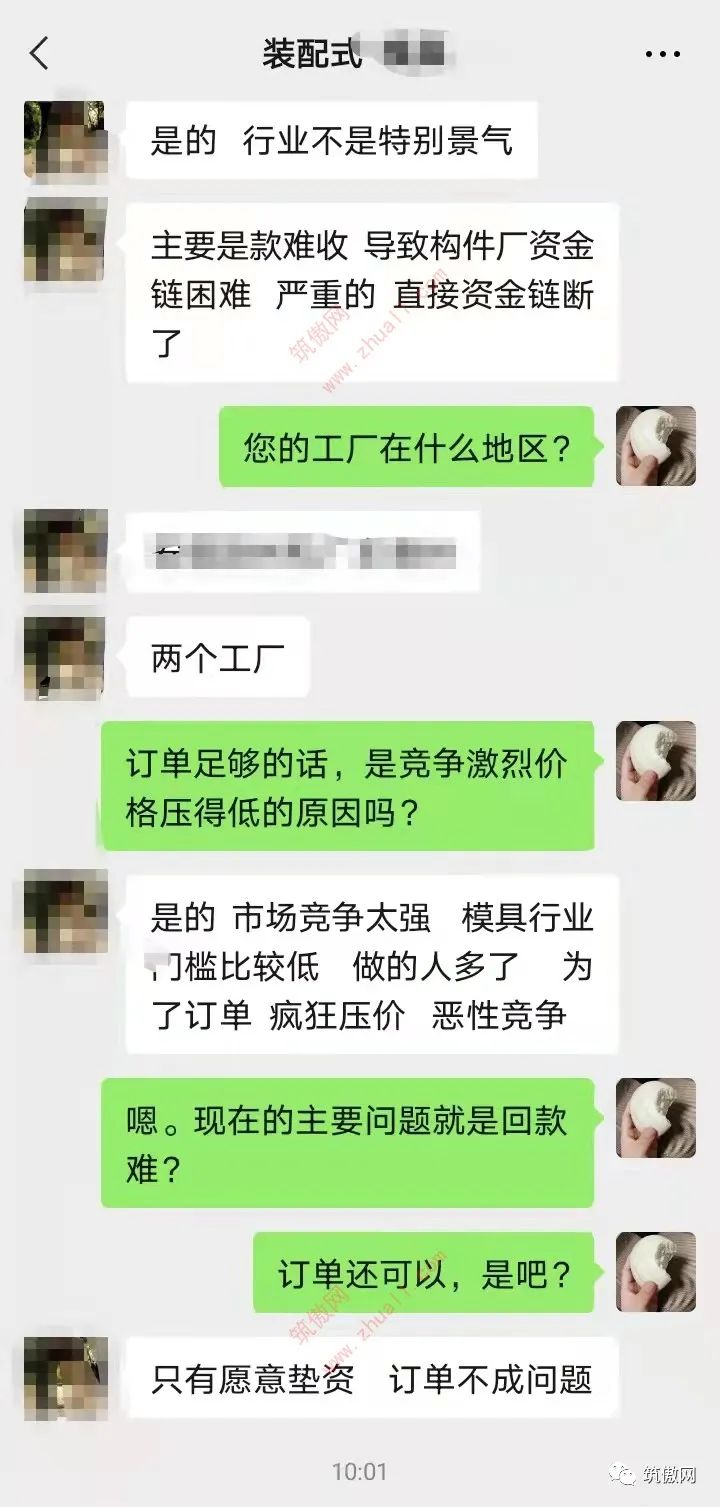

The layout of component factories around the country is uneven, the competition is fierce, and some component factories have few unit orders, be on short commons; 2.

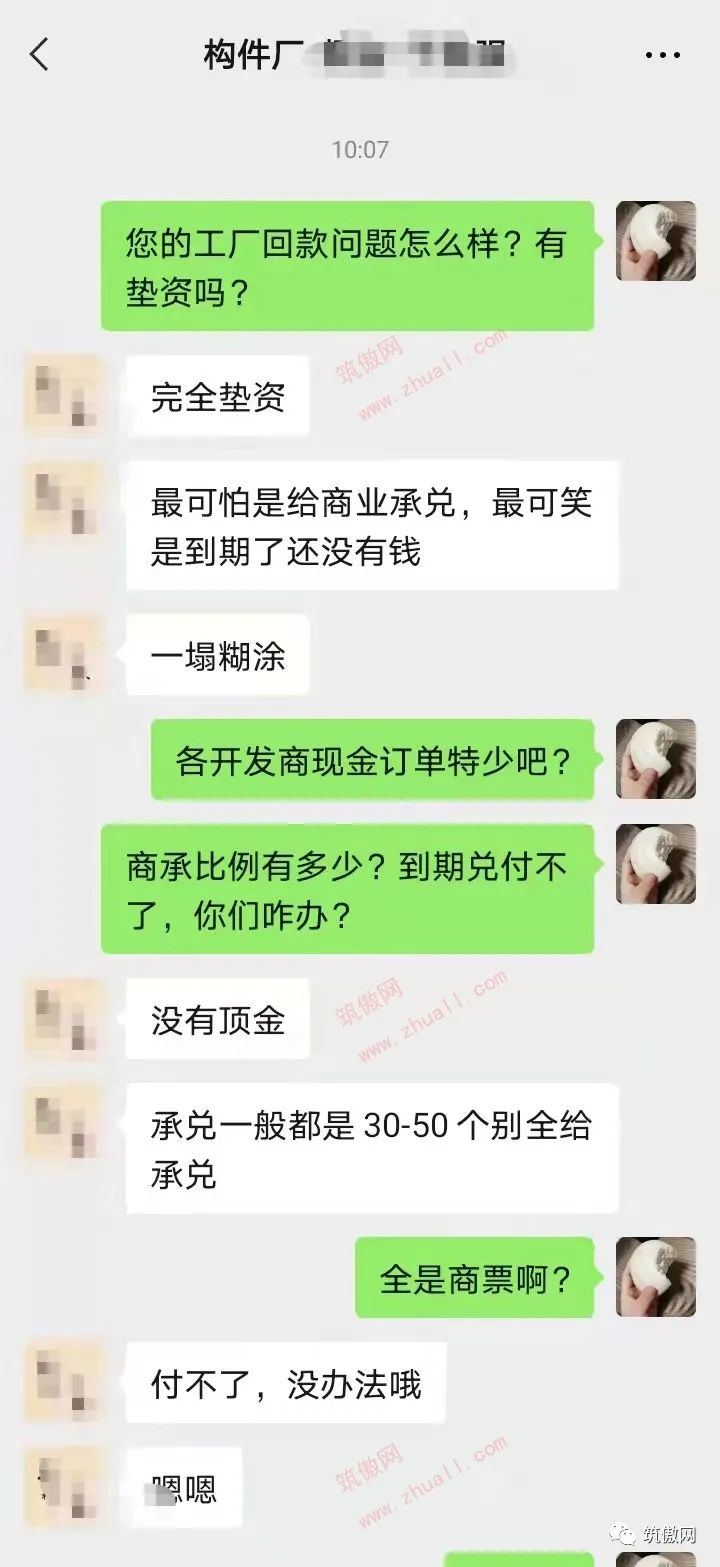

Raw materials such as reinforcement, gravel and cement need to be paid in cash, while the supply of components is subject to commercial acceptance, and the advance is serious; 3.

It is difficult to ask for money if the commercial bill cannot be cashed or delayed normally and the payment cannot be collected normally; 4.

The competition among component factories is fierce, the price is low, and some component types have no profit; 5.

The survey in Beijing and its surrounding areas is better than other feedback received.

2、 About the operation of PC component mould manufacturers ▲ PC stair steel mould ▲ PC laminated plate steel mould ▲ PC shear wall plate steel mould synthesis: the current operation of the mould factory: 1.

The order can be basically guaranteed; 2.

Low threshold and increase in the number of manufacturers entering the industry; 3.

Malicious competition, low prices, thin profits, do not make money.

The above questions are about the current business situation of fabricated component manufacturers + mold manufacturers.

What are the problems in your factory? How to solve it? Welcome to leave a message in the comment area for discussion.

We will select a wonderful selection to display! ● the design error of prefabricated exterior wall joint of prefabricated building leads to water leakage, so we must be careful ● the upper surface of post cast concrete of prefabricated wall joint is not provided with rough surface, which is wrong? ● the prefabricated column with keyway at the bottom of the prefabricated building shall be provided with exhaust hole.

Did you miss it? ● how much do you know about the “four seam” joint design of fabricated building laminates? ● you may not understand the “new” technology of prefabricated buildings and the “old driver” of prefabricated buildings ● “sandwich” prefabricated outer wall outer leaf plate falls off, which is wrong? ● prefabricated buildings should adopt the same floor drainage ● dry construction method of prefabricated buildings, floor and ground, “separation of bone and flesh” ● internal partitions of prefabricated buildings are not masonry, what do you know? ● precast circular orifice shear wall! Fabricated without grouting sleeve ● have we seen the shear wall without grouting sleeve and the frame structure without grouting sleeve? ● the “diagnosis” and “antidote” of the thickness of the protective layer of fabricated prefabricated components● how to reduce the weight of the “sandwich” sandwich insulation prefabricated exterior wall? ● grouting sleeve! Code for non connection of vertically distributed reinforcement passed the review! ● water leakage at joints of fabricated building exterior walls? what to do? ● “beard tendon”? How to design non reinforced composite plate components? ● how to design the lifting points of prefabricated PC boards for prefabricated buildings? ● how many times can the prefabricated component mould be reused because it is so expensive? ● prefabricated building components must not work with “rust”! ● how to reduce amortization due to high consumption and high cost of fabricated molds? ● requirements for design, management, manufacture, processing and use of prefabricated precast component molds ● key points for design and manufacture of prefabricated concrete component molds for prefabricated shear wall structures ● new gadgets you haven’t seen, 3D printing molds for prefabricated precast components..