At present, many civil buildings adopt high-performance autoclaved sand aerated concrete block wall self insulation system in the thermal insulation design.

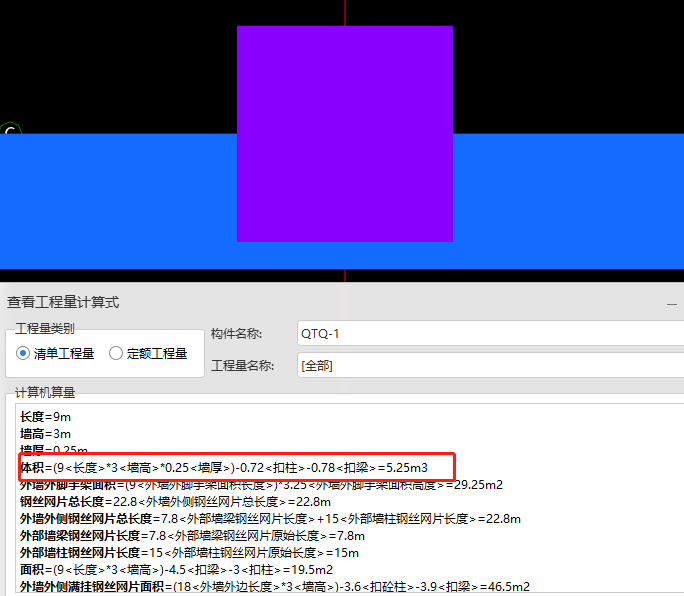

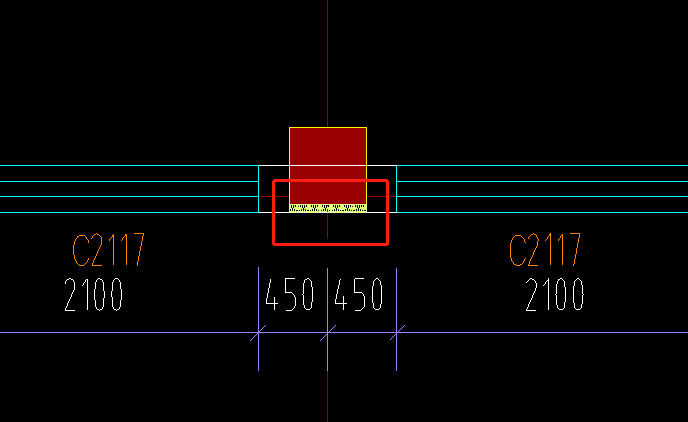

Generally, the thickness of the outer wall is 250mm, and 50mm high-performance autoclaved sand aerated concrete block is pasted at the beam column thermal bridge, which is flush with the outside of the masonry on both sides, As shown in the following detail drawing: the existing thermal insulation components in gtj2021 version can not completely solve this problem, but we can use other components to replace thermal insulation components and measure accurately.

First, let’s take a look at the calculated thermal insulation components in the software: 1.

There is a “thermal insulation wall” in the wall component.

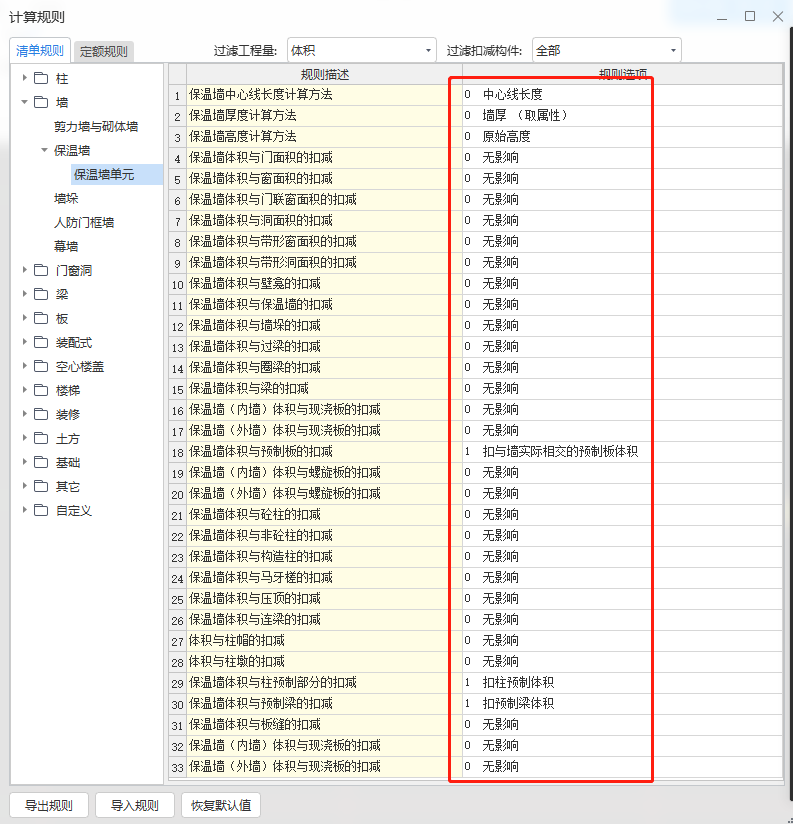

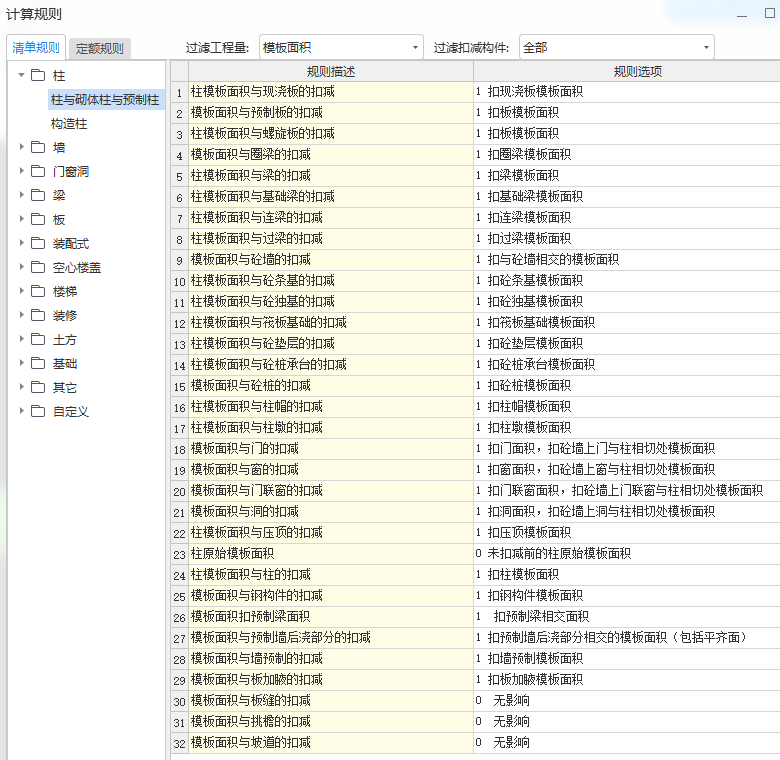

The volume deduction in the built-in calculation rules of the software is shown in the figure below.

It can be seen that it has no impact on the deduction relationship with other components.

If you want to use this component to draw the thermal insulation exterior wall, you should refer to the masonry engineering list or quota rules, Modify one by one.

I believe you don’t have the patience to modify, so it’s not applicable to use this insulation wall component to draw external wall insulation.

2.

There is also a “thermal insulation layer” component among other components, but it is a decorative component, which can only be arranged in the wall and breast board components.

If you want to use the decoration components to calculate the thermal insulation and masonry volume deduction in the above schematic diagram, it is still troublesome, and we do not recommend it here.

Since the above two components are not suitable for calculating similar insulation systems, we need to think of other methods.

The premise is that the quantities in the volume list can be deducted by masonry components, the surface layer can be arranged and decorated, and the quantities in the list of formwork of adjacent column components can not be deducted.

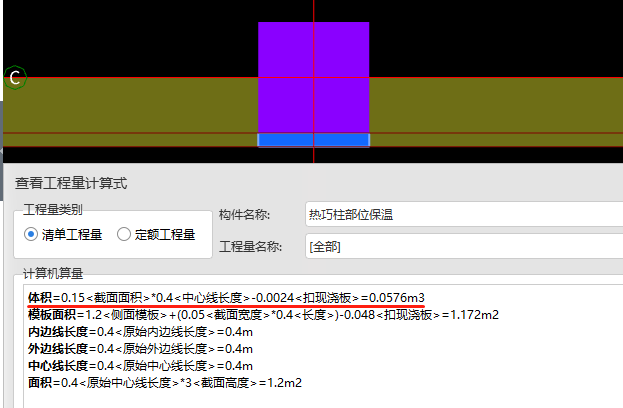

It is a non software breast board component that can meet many needs.

The default breast board calculation rules of the software are as follows: (1) the deduction relationship between the formwork of the concrete column and the breast board: it can be seen from the screenshot above that the formwork of the concrete column has no option to deduct the breast board, which meets the requirements.

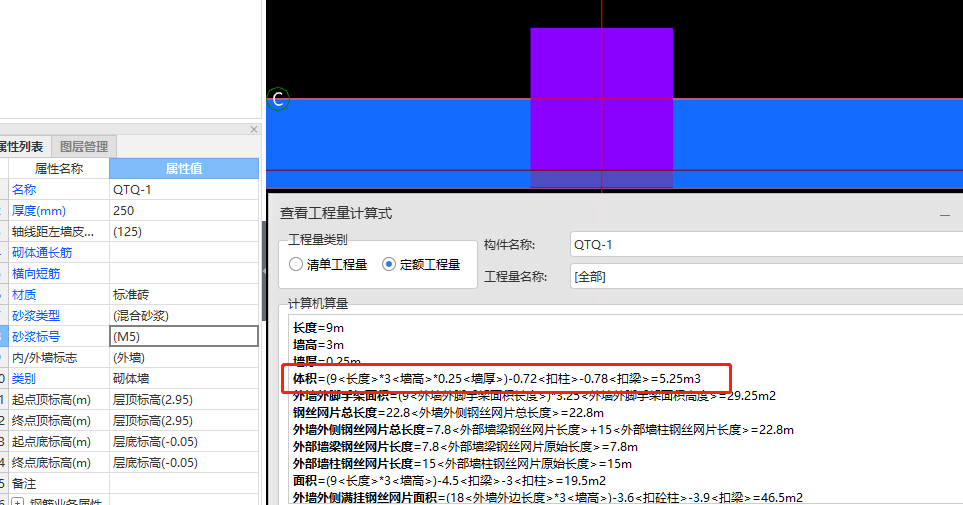

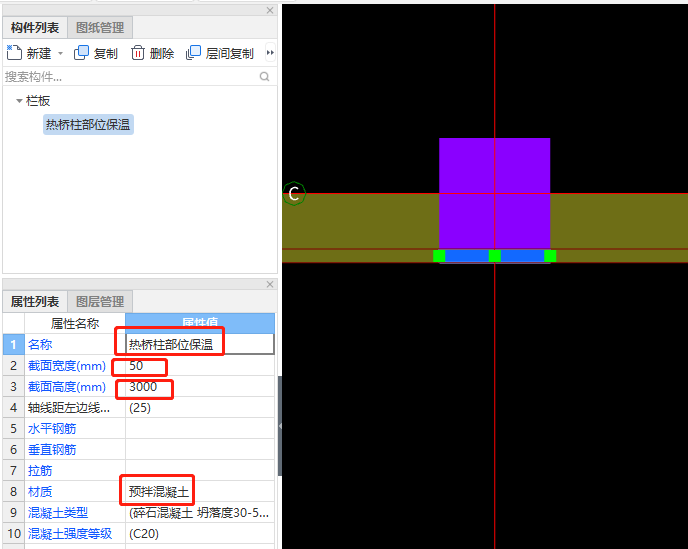

Then, carry out the actual operation: first draw the 250mm thick wall, connect it at the insulation part, and then draw the insulation part with the breast board component, which is named “thermal bridge column insulation” , the thickness of the breast board is the thickness of the insulation layer, the height of the breast board is modified to the layer height, and the material is the default concrete.

After completion, it is summarized and calculated, so that the quantities of the insulation bill attached to the column can be measured.

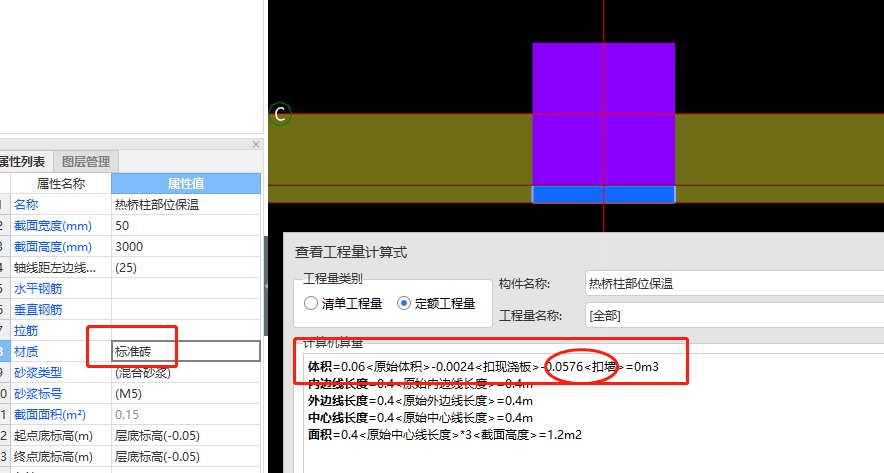

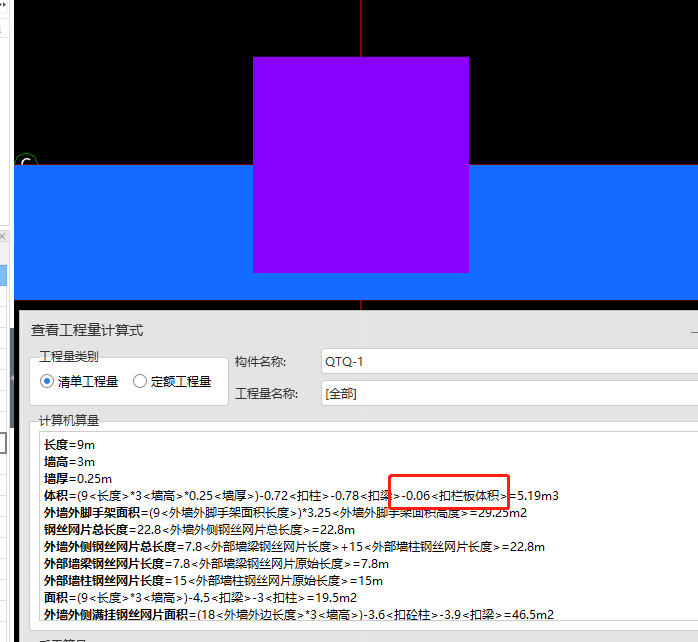

(2) Calculation results of breast board material as concrete: it should be noted here that if the breast board material is changed to “standard brick”, the bill of quantities of adjacent masonry will not deduct the volume occupied by the breast board, so the material cannot be modified.

The bill of quantities of masonry when the breast board is standard brick: (3) Masonry quantities when the breast board is made of concrete: if you want to work out the quota quantities, there is another difference in the above comparison: when the breast board is made of “standard brick”, the quota quantities of the breast board are “0” , the quantities of breast boards are not deducted from the quota quantities of adjacent walls: similarly, the insulation of thermal bridge beams can also be accurately measured by drawing breast board components* This article was originally written by Wang Botao and contributed exclusively.