1、 Application background 1.

Factories that produce large-scale components according to industrial requirements generally need to assemble and test each section and layer in advance before the products leave the factory, so as to ensure that the dimensions meet the installation accuracy and ensure smooth installation and qualified quality after transportation to the site.

2.

Current situation and pain point: if steel ruler is used to measure the distance, the method is complex, the measuring personnel are tired, the efficiency is low, the time is long, and the accuracy is affected by the professional degree of the measuring personnel.

Once the gauge is exceeded, it needs to be reworked, which will greatly increase the cost.

Fig.

1 in practice, the traditional manual steel ruler method also adopts the method of testing and installing in advance.

Due to the large volume and heavy weight of each component, it is generally produced in different workshops.

It is necessary to hoist each component to a large workshop, and then actually splice and install them together.

Although this method of installation test has achieved the expected test purpose, it needs a lot of time and manpower.

Is there a way to obtain dimensional information in all directions and accurately judge whether the assembly is qualified or not, and to save time and labor and reduce costs without actual installation? Three dimensional laser scanning technology provides a very good choice.

2、 The new scheme is applied.

Firstly, the Leica rtc360 ultra fast 3D laser scanner is used to collect hundreds of millions of high-precision 3D coordinate points on the surface of the component to obtain a high-precision 1:1 model.

Then, the point cloud is pre processed in the supporting Leica cyclone point cloud ultra fast processing software.

Finally, the virtual installation test is carried out in the professional cyclone 3DR software, which greatly shortens the installation test time and reduces a lot of costs.

3、 Application case 1.

Project overview location: a large-scale factory content: for large-scale workpieces produced, two or more workpieces need to be pre installed.

Requirements: field point cloud scanning and data processing compare the speed of traditional methods and three-dimensional laser scanning methods to conduct virtual installation test and check the dimensional accuracy of virtual installation.

2.

Operation process 1) existing model data sorting according to design and processing, Obtain the theoretical three-dimensional geometric model of splicing installation 2) field point cloud collection uses the scanner to measure the three-dimensional point cloud of the outer contour of the component.

Generally, it is impossible to scan all the contours at one time, and it needs to convert the scanning station for many times.

Fig.

2 3D laser scanner obtains the point cloud of the component surface.

Leica rtc360 3D laser scanner operation actual measurement: no target is required during the scanning process, rtc360 visual tracking realizes automatic splicing without leveling, It can be measured when it is placed stably.

The single station operation time is fast, and the medium resolution is 51 seconds for one station.

A total of 8 stations are scanned, with a time of 10 minutes.

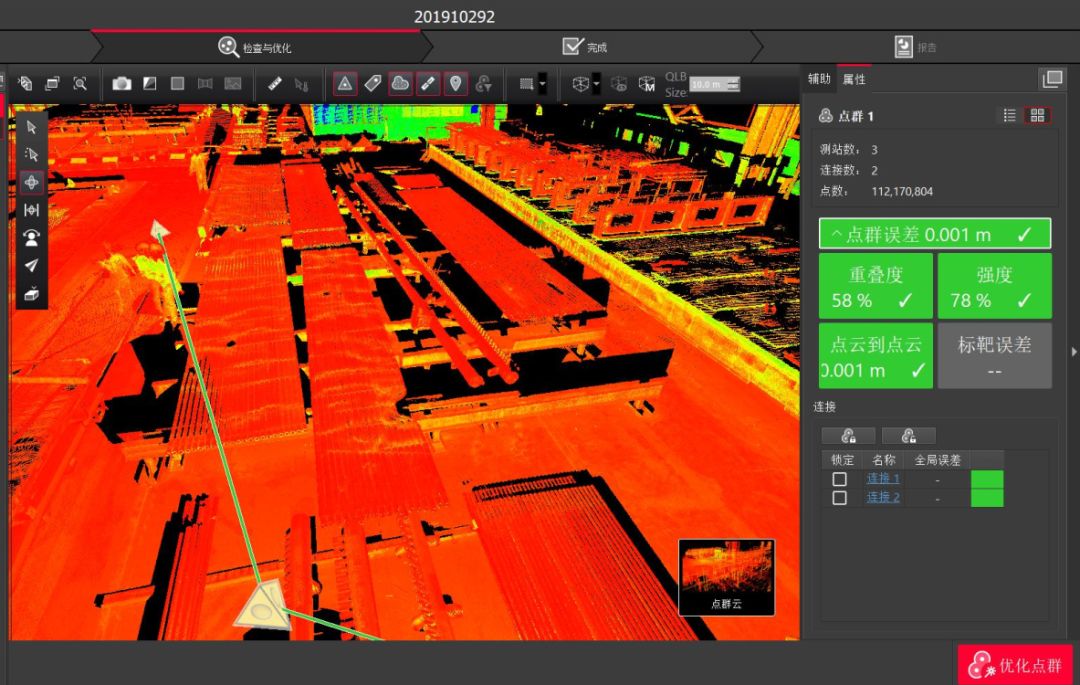

3) The measured data of point cloud splicing is imported into cycloneregister360 point cloud processing software for pre-processing such as splicing, and the three-dimensional point cloud data of the outer contour points of each solid component is formed.

The software can automatically splice the point clouds obtained by multi station scanning, and generate reliable precision splicing reports.

The processing process is intuitive and simple.

It takes less than 10 minutes to complete the splicing of 8 stations’ data, and the splicing error does not exceed 1mm.

Fig.

3 Leica register360 software automatic point cloud splicing 4) point cloud segmentation and de-noising delete irrelevant part of point cloud data, and only pre installed components are retained Fig.

4 point cloud data of each component is obtained after de-noising Fig.

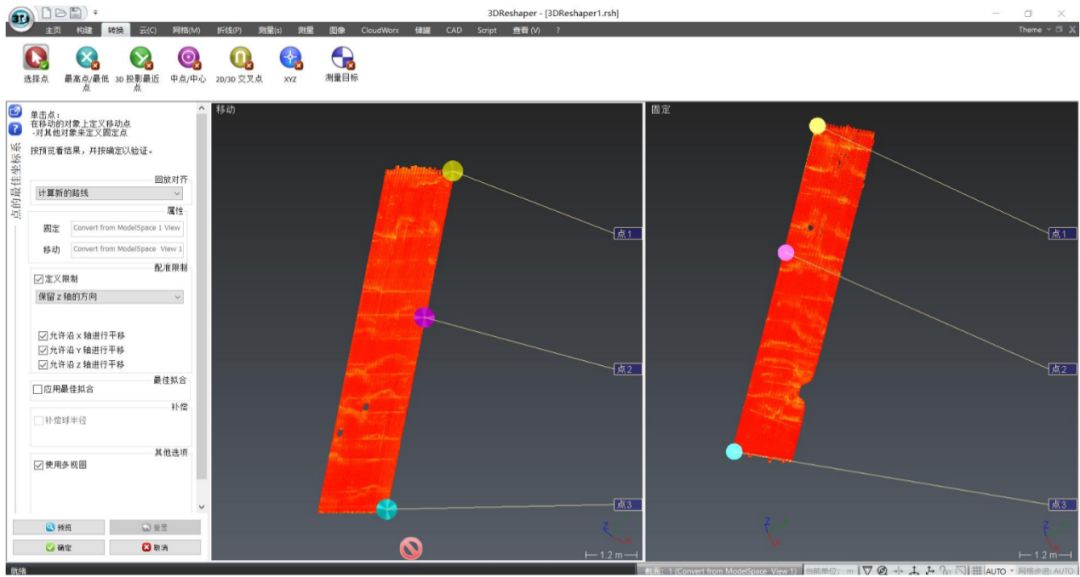

5) coordinates are unified, and coordinates of segmented components are merged and converted into unified overall coordinates by common point fitting Fig.

5 fitting and coordinate transformation 6) output point cloud model coordinates of simulation installation results are unified to complete simulation assembly, The dimension measurement can be carried out to obtain the deviation results such as the interface elevation and pipe center distance of each rigid beam member.

Figure 6 if the pre installation deviation of rigid beam exceeds the limit, it shall be adjusted and corrected until the error meets the installation accuracy requirements.

3.

The accuracy verification of the new 3D laser scanning scheme is to check the whole after installation with a steel ruler and compare the two results.

The error fully meets the installation accuracy requirements of ± 5mm.

Through the accuracy verification of steel ruler and design value after installation, the ultra-high scanning accuracy of rtc360 is fully proved.

Leica rtc360 3D laser scanning solution fully meets the accuracy requirements in the pre installation of large workpieces.

Fig.

7 comparison results with inspection points IV.

summary: Leica rtc360 3D laser scanner has many advantages in the pre installation of large components, mainly reflected in: high efficiency: high scanning efficiency, and one-stop scanning can be completed in 26 seconds at the fastest; There is no need for transportation and hoisting.

Compared with the original need to transport all components to the same workshop for actual installation, the new Leica rtc360 scheme can be directly installed in the original workshop, reducing the intermediate transportation links; The splicing is simple and fast.

The VIS visual tracking system provides convenience and guarantee for later data splicing, and the splicing time is greatly reduced.

Compared with the hoisting method, it takes at least half a day to complete the whole pre installation process with rtc360 in less than one hour.

High accuracy: Leica rtc360 has reliable accuracy, scanning accuracy of 1mm, reliable data splicing accuracy, no stratification of point cloud, and high accuracy of point cloud results.

The example shows that the accuracy of Leica rtc360 meets the requirements and is a reliable data acquisition means.

More intuitive: three dimensional virtual installation technology, through cyclone3dr software, more intuitively shows the effect of assembly of various components according to the design requirements, and the required information of key positions and dimensions is clear and accurate, providing accurate and intuitive basis for installation and adjustment.

“Only one person is required for on-site operation.

The operation is very simple and convenient, and the results are illustrated.

We will write this method into the technical transformation plan!” This sentence is the true expression of the customer’s inner thoughts..