Today’s Encyclopedia prefabrication building network finishing and editing No.

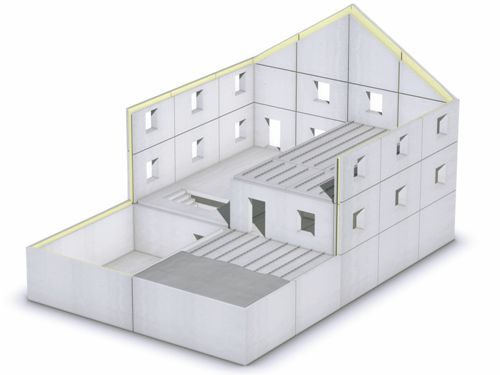

39 June 14 2022 takes you a minute to learn about prefabricated building concrete prefabrication concrete prefabrication, English: precastconcrete, so it is also called PC component, which refers to the concrete products processed and produced in the factory through standardized and mechanized methods.

The corresponding traditional cast-in-place concrete requires on-site mold making, on-site pouring and on-site maintenance.

Precast concrete units are widely used in construction, transportation, water conservancy and other fields, and play an important role in the national economy.

Part I advantages compared with the cast-in-place concrete, the factory produced concrete precast units have many advantages: safety: for construction workers, the relatively stable working environment in the factory has a higher safety factor than the complex site operation; Quality: the quality and process of building components can be better controlled through mechanized production; Speed: the standardization of dimensions and characteristics of prefabricated parts can significantly accelerate the installation speed and construction progress; Cost: compared with the traditional on-site mold making, the mold in the factory can be reused and recycled, and the comprehensive cost is lower; Mechanized production requires less labor.

With the rising labor cost, the cost advantage of prefabricated parts produced in large scale will become more obvious.

Environment: the on-site operation volume of the construction site with prefabricated parts is significantly reduced, and the dust pollution and noise pollution are significantly reduced.

In the second part, the inferior factories need a large area of storage yard and supporting equipment and tools, and the storage cost is high; The construction team with professional training is required to cooperate with the installation; The high transportation cost and risks determine the limited market radiation..