On May 23, Jinxi new materials, a subsidiary of Jinxi green construction industry group, an important part of Jinxi group’s extended industrial chain, independently developed and produced the first batch of PC prefabricated component balcony boards, which were successfully delivered and delivered to customers.

This indicates that Jinxi has taken another solid step in extending the industrial chain and developing prefabricated buildings, further enhancing the group’s development stamina and competitiveness, helping to improve the building quality, and has practical significance in promoting green development.

The development of prefabricated buildings is not only a green construction mode vigorously promoted by the state, but also an important measure to realize building industrialization.

Prefabricated buildings have the characteristics of high quality, high efficiency, energy saving and environmental protection.

They have broad market prospects and considerable social benefits.

In the field of prefabricated buildings, PC components are prefabricated in the factory, then transported to the construction site for assembly, and then the reinforced concrete is overlapped and poured.

Such industrialized and industrialized buildings have been widely promoted in Europe, America and Japan.

PC prefabricated component balcony plate is a kind of PC prefabricated component of prefabricated building.

Through standardized design, factory production, assembly hoisting, integrated decoration and information management, it integrates various business fields such as R & D design, production manufacturing and field assembly.

Compared with the traditional cast-in-situ concrete balcony, it has the advantages of controllable cost, controllable quality and controllable project progress.

Over the years, Jinxi group has implemented the relevant national industrial policies, continuously deepened the supply side structural reform, and solidly promoted the transformation and upgrading with the strategy of “specialized, long, refined and high” to build the world’s largest profile steel production and application base.

To grow, rely on the advantages of section steel, extend the industrial chain, and innovate and develop four major industries such as prefabricated steel structure building, green pile foundation, power tower, and nuclear power precision valve equipment manufacturing.

Through the establishment of green construction industry group, various links such as profile steel plant, Research Institute, Design Institute, industrial park, real estate and customers are connected in series, forming a green full life cycle and full industrial chain integrating R & D and production of profile steel, architectural research and design, deep processing of steel structure and integrated supply of products.

The green building material PC board project of Jinxi new material prefabricated building of green construction industry group is an important link of the group’s integration into the coordinated development of Beijing, Tianjin and Hebei, the realization of green butterfly transformation, transformation and upgrading, and the opening up of the whole industrial chain of Jinxi green steel structure building.

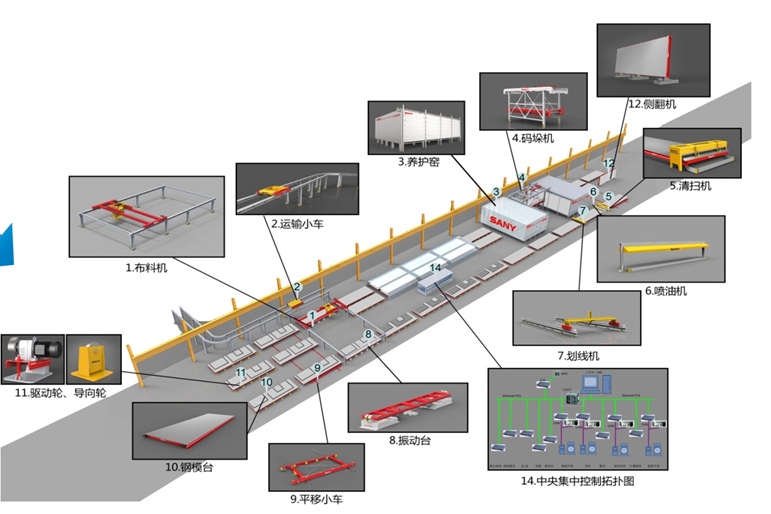

At present, it has 4 PC prefabricated component production lines, all of which use the most advanced generation III equipment of Sany Heavy Industry, the largest construction machinery manufacturer in China.

The equipment has high quality rating and fast operation speed.

It is the most efficient, energy-saving and logistics convenient prefabricated building PC production line in China, with an annual production capacity of 300000 cubic meters of PC prefabricated components.

Based on the industrial intelligent manufacturing mode, the company comprehensively innovates the traditional building production mode and provides customers with an integrated green building solution integrating design, manufacturing, development, construction and operation services.

The process technology of Jinxi PC prefabricated component production process flow project is the top in China.

It adopts PC Intelligent Manufacturing Execution System (spci-mes) to guide the production of prefabricated components by means of visual data, dynamic monitoring, automatic flow and other methods, taking the mold task as the guide, taking the advantage of drawing directly driving the automatic operation of equipment, and monitoring the production line as the basis, so as to realize the comprehensive management of factory automation, intelligence and informatization.

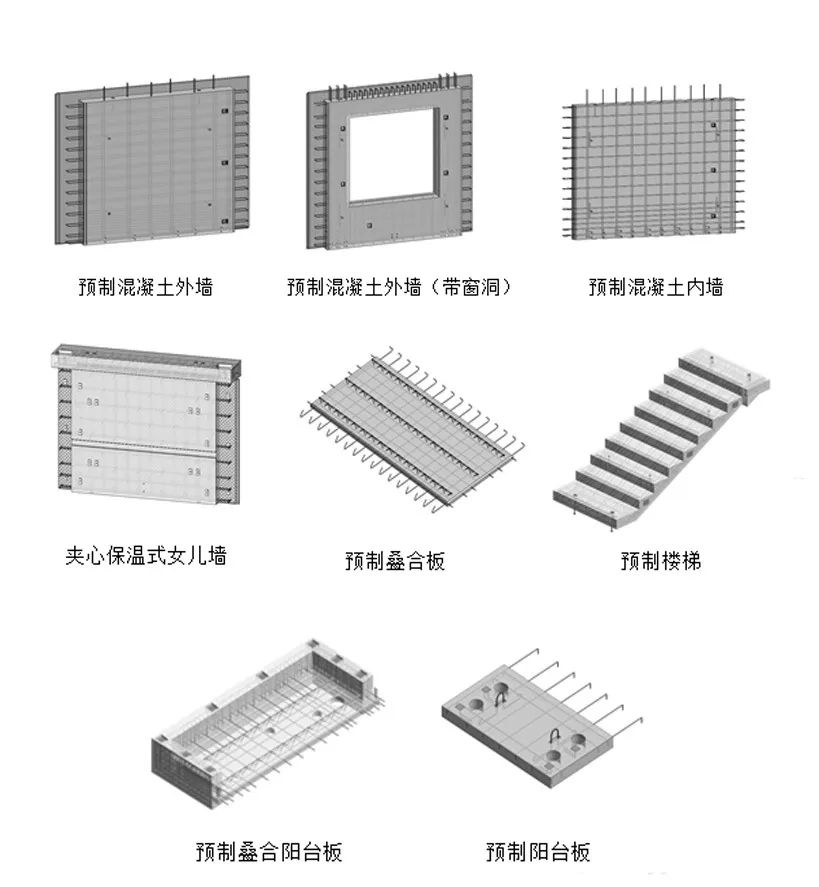

Jinxi PC prefabricated component products can produce prefabricated laminated panels, patented exterior wall panels, interior wall panels, prefabricated stairs, balcony panels, prefabricated columns, beam columns and other products through the processes of mold cleaning, reinforcement distribution, embedding, pouring, tamping, curing, demoulding and finished product inspection.

They are widely used in residential buildings, writing buildings, hospitals, schools, transportation, municipal and water conservancy buildings.

Related links: PC prefabricated components have many advantages over cast-in-situ concrete: ☆ mechanized production, better control of quality and technology.

☆ the mold is repeatedly used to save resources.

☆ fast construction speed and low comprehensive cost.

☆ the construction is not affected by the season, which is convenient for accelerating the project progress.

☆ reduce dust, noise and other pollution, which is conducive to environmental protection…