The support system is generally arranged in three layers, which is the same as the common steel pipe full support.

Key control of molding quality 1.

Characteristics of laminated slab 1.

Quality control measures: 1) sponge strips shall be pasted at the joints of laminated plates, and the position of sponge strips must be accurate.

(2) The thickness of precast slab of laminated slab shall not be less than 60mm, and the thickness of post cast concrete laminated layer shall not be less than 70mm; When the precast slab of the laminated slab adopts hollow slab, the cavity at the slab end shall be blocked; Truss reinforced concrete composite slab should be used for composite slab with span greater than 3m; Prestressed concrete precast slab should be used for laminated slab with span greater than 6m; Concrete hollow slab should be used for laminated slab with slab thickness greater than 180mm.

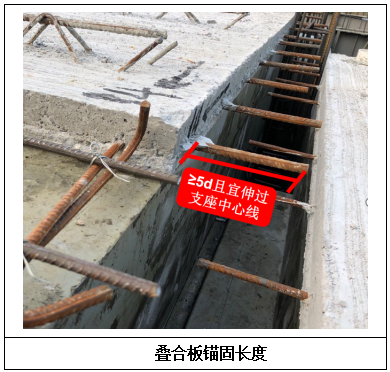

The anchorage length should not be less than 5D (D is the diameter of the longitudinal stressed reinforcement) and should extend beyond the center line of the support.

The prefabricated concrete thin plate is used as the permanent formwork at the bottom, and the cast-in-situ concrete composite layer is poured at the upper part.

(3) The sponge strip shall be pasted at the seam of the laminated plate, and the position of the sponge strip must be accurate; Two edge lines of precast slab shall be snapped on the formwork, and the sponge strip shall be firmly pasted along the edge line.

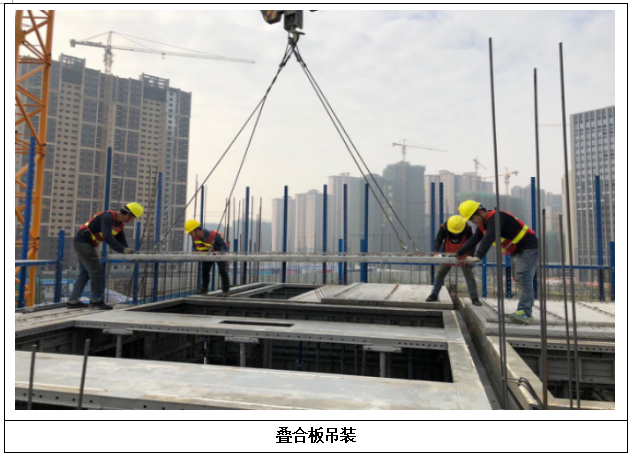

The components shall be clearly marked with lifting points, attachment points and pull nodes.

In the early stage of the laminated plate hoisting project, the load of prefabricated components shall be rechecked for tower crane selection, and the tower crane must fully cover the fabricated building and the stacking area of laminated plates.

4) An independent support shall be added on both sides of the joint of the laminated plate..

When lifting, the horizontal included angle of the sling shall not be less than 60 ° and not less than 45 °, that is, the length of the steel wire rope of the laminated plate member shall not be less than 3m.

PART1.

The number of stacking layers shall not be greater than 6 layers, and stabilization measures shall be taken.

(4) The line pipe runs under the laminated plate truss to avoid trampling on the line pipe, protect the line pipe and ensure that the line pipe is not exposed after the completion of ground pouring.

2) The formwork support and reinforcement at the plate strip position are not in place, resulting in formwork deformation and slurry leakage after concrete pouring.

(6) At the junction of negative reinforcement, the distribution reinforcement is bound under the truss reinforcement to avoid the reduction of protective layer caused by the intersection of multi-layer reinforcement and affect the flatness of cast-in-situ surface.

After the pouring, the concrete shall be cured by covering film and watering.

3.

3.

(5) When binding the reinforcement of the laminated plate, the negative reinforcement of the support and the row frame reinforcement shall be fully bound, the anchor spacing of the stiffener shall be set, and the binding of the nodes at the position of the post cast strip shall meet the requirements of the drawing.

2) The gap between the laminated plate and the formwork is large, and the rubber strip cannot ensure all sealing.

After pasting, the precast slab shall be installed in time.

2.

4.

Main causes of slurry leakage: 1) the sponge adhesive strip at the plate and strip position is not pasted in place.

Skids shall also be set between each layer of thin plates, and the skids shall be aligned up and down.

The laminated plate shall be hoisted 50 cm above the ground, and the stress of steel wire rope and hook shall be checked to keep the laminated plate horizontal, and then hoisted over the operation layer.

The laminated floor slab can save formwork, and the upper and lower surfaces of the slab are flat, which is convenient for the decoration of the finishing layer.

Requirements for the mobilization of laminated plates 1.

Key points of support erection.

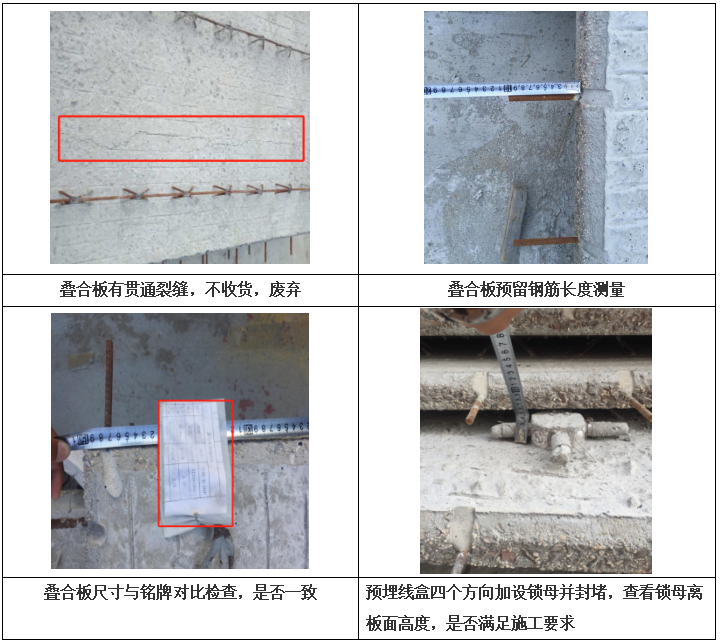

It is required that there shall be no serious defects in appearance quality, and there shall be no exposed reinforcement and honeycomb, pitted surface and cracks affecting the service performance of the structure.

The two parts of concrete are stressed as a whole to form an assembled integral composite floor.

PART4.

4.

2.

(7) Before concrete pouring, clean the impurities on the laminated plate and spray water on the upper part of the laminated plate to ensure that the surface of the laminated plate is fully wet, but there should not be too much open water to affect the performance of the concrete.

2.

Construction process of laminated slab (1) at the slab end support, the longitudinal stressed reinforcement in the precast slab should extend from the slab end and be anchored into the post cast concrete of the supporting beam or wall.

Its principle should ensure that the concrete strength of the cast-in-situ layer reaches the standard formwork removal strength.

Cushion blocks shall be set at the lower part of each laminated plate, and the position of cushion blocks under the components shall be consistent with the lifting position during demoulding and hoisting.

3) The laminated board itself is warped and the bottom of the board is uneven.

The hoisting shall be stopped when the wind is above level 5.

Prefabricated PC component – prefabricated composite slab composite floor is a structural form combining prefabricated floor and cast-in-situ floor.

Construction process 2.

2) After the installation of the cast-in-situ slab joint roof formwork, two precast slab edge lines shall be popped on the formwork, and the sponge strip shall be firmly pasted along the edge line.

The laminated plates shall be stacked with trusses stacked upward, and inversion is strictly prohibited.

The laminated slab has good integrity and continuity, which is conducive to enhance the seismic performance of the building.

Other reasons: 1) after the hoisting of the laminated plate is completed, fine adjustment is made and the sponge rubber strip is damaged due to human prying.

PART2.

The superimposed floor slab reduces the amount of on-site concrete pouring and reduces the noise pollution during concrete vibration, which is in line with the policy of energy conservation and emission reduction.

Site quality acceptance of laminated plates part3 Construction process of laminated slab 1.

3.

When the prefabricated components enter the site, each component must be accepted, mainly focusing on the appearance, specifications and dimensions of the components.

After the pasting, the precast slab shall be installed in time.

The layout of independent steel support is based on the following principles: the spacing of independent steel support along the supporting beam is determined according to the calculation of upper load and beam stiffness, which generally does not exceed 2m; The spacing between supporting beams is controlled by the stiffness of the laminated plate itself, which generally does not exceed 1.8m; The distance between the supporting beam and the supports on both sides of the laminated plate (the laminated plate is cantilevered with the beam as the temporary support) shall not exceed 0.5m; The laying direction of the supporting beam is perpendicular to the direction of the laminated plate lattice reinforcement.

The concrete curing shall not be less than 7 days.

The construction progress of composite floor slab is fast, which can shorten the construction cycle, improve work efficiency, save labor and reduce construction cost.

The independent steel strut is retractable and fine tuned, which is mainly used for the vertical support of the horizontal structure of prefabricated components, and can bear the dead weight of beam and slab structure and construction load.

The lower support of laminated slab adopts tool support system, which is composed of aluminum I-beam, special bracket, independent steel pillar and stable tripod.

During the pouring of laminated plates, special attention shall be paid to vibrating and compacting with flat plates to ensure that the laminated plates are combined into a whole.

3) The post cast part of the joint of the laminated plate is embedded with a plywood (the aluminum mold can be pasted and fixed with double-sided adhesive tape) to effectively prevent slurry leakage.