From August 31 to September 5, the theme of the 2022 China International Trade in Services Fair was “service cooperation promotes development, green innovation and ushers in the future”.

The company’s Mentougou Prefabricated Parts Factory was successfully held in Beijing, making a stunning appearance at this trade in services fair.

The China International Trade in Services Fair is the only national, international and comprehensive service trade platform in the world, and has been held in Beijing every year since 2012.

Jointly organized by the Ministry of Commerce and the Beijing Municipal People’s Government, and supported by WTO, the United Nations Conference on Trade and Development, OECD and other international organizations, it is the only comprehensive service trade fair covering 12 major areas of service trade in the world.

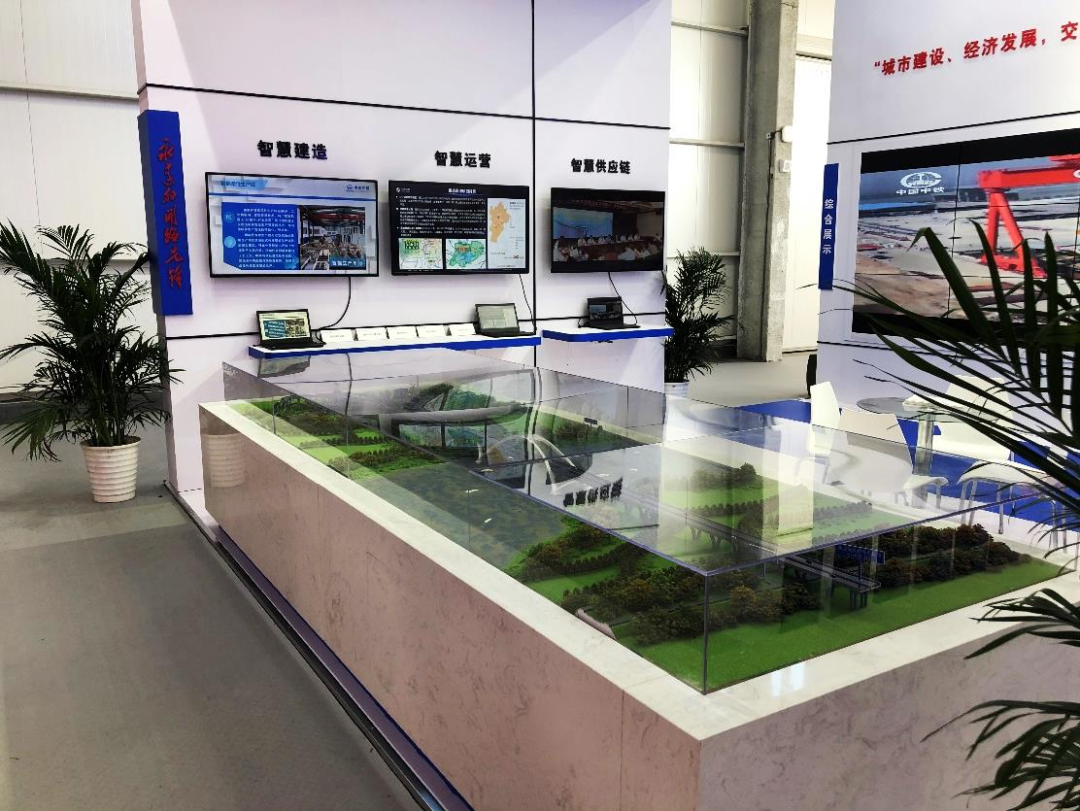

In this exhibition, the company’s Mentougou Prefabricated Component Factory displayed the whole process intelligent flexible production line of prefabricated components, the “central” intelligent management system, the finished products of ordinary concrete prefabricated components and cement based composite prefabricated components.

Echoing the theme of this trade fair, the component factory takes “safe production, quality first” as the basic principle, “green environmental protection, energy reduction and consumption reduction” as the concept, “new materials, new technology” as the starting point, comprehensively uses 5G, industrial Internet of Things, intelligent sensor technology, integrates “intelligent robot+AI technology+industrial application”, and develops a new mode of prefabricated intelligent production management, Promote the lean and intelligent production management of pre products.

The component factory has both the efficiency of mass production and the flexibility of small batch production.

It keeps the tooling equipment at each station close to the actual situation of the site, and uses weight sensors, intelligent working platforms, visual recognition, precision positioning and other technology to enable the development of the production line roller table into a multi-purpose production line suitable for the production of multiple products.

The prefabricated parts use the mold and die platform technology, and the mold and die platform are connected by pressing plates, Realize the rapid replacement of different types of molds, greatly improve the production efficiency of components, and promote the intelligent transformation and upgrading of prefabricated components; Through digital, networked and intelligent management, a safe, environment-friendly, high-quality and efficient lean management system of “people, machines, materials, methods and environment” has been realized, which provides a technical demonstration benchmark for the digital and intelligent upgrading of the infrastructure market in the future.

(Chen Wei) ❖ Editor: Liu Jiahan Reviewer: Song Gang Submission Email: sanjupujia@126.com 。.