1.

The low degree of design standardization is the number one problem restricting the current development of precast buildings.

Since the issuance of the guiding opinions of the general office of the State Council on vigorously developing precast buildings (GBF [2016] No.

71 document) in 2016, the development of precast buildings has been more than five years, and the area of precast buildings in China has reached 630 million square meters [1].

Document No.

71 defines the six characteristics of precast buildings, namely “standardized design, factory production, assembly construction, integrated decoration, information management and intelligent application”, and puts “standardized design” in the first place, because design is the leader and has a great impact on subsequent production, transportation and construction, And the degree of standardization of design has a decisive impact on the project cost.

However, the practice in various places shows that the design standardization is not well done, which has become the number one problem among many factors restricting the development of precast buildings.

In many construction projects, the architectural design is very complex, the degree of standardization is low, and there are many kinds of parts (components), resulting in many mold specifications, low reuse rate, difficult cost amortization and high final cost; At the same time, the low degree of standardization of the design also has great constraints on the construction, resulting in great construction difficulties, many processes, great coordination difficulties, difficult to ensure the accuracy, and the final building quality can not meet the expectations.

In short, low design standardization has seriously restricted the improvement of quality and efficiency of precast buildings.

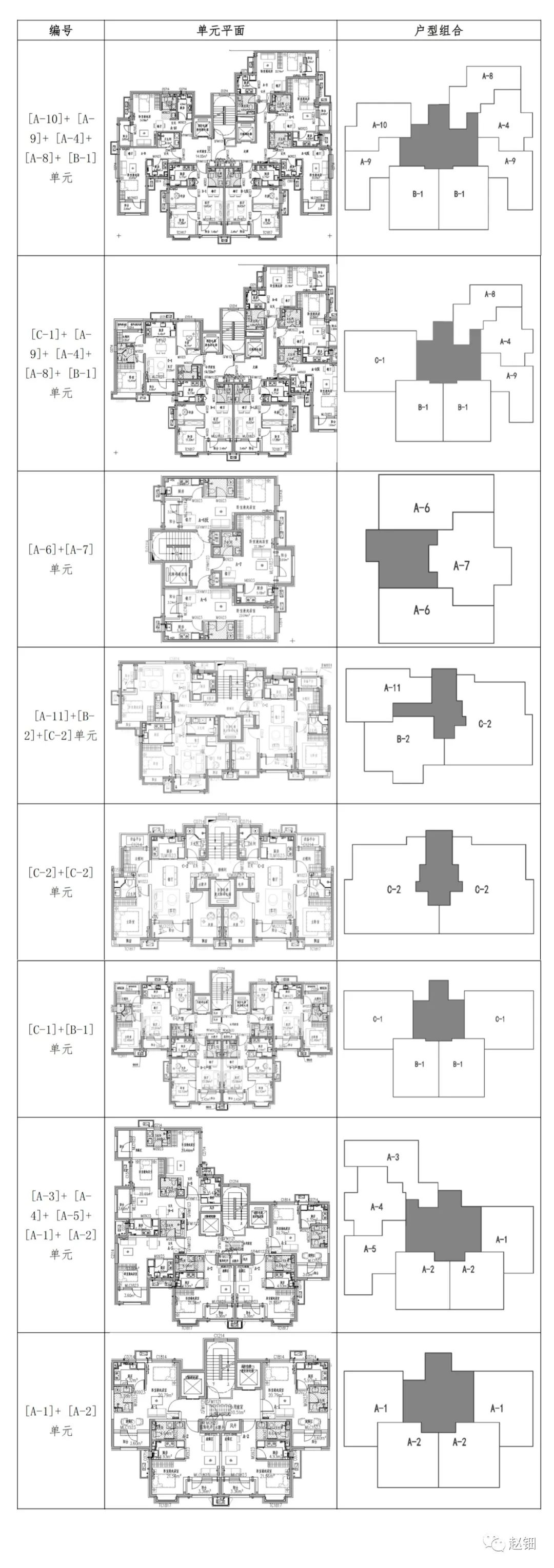

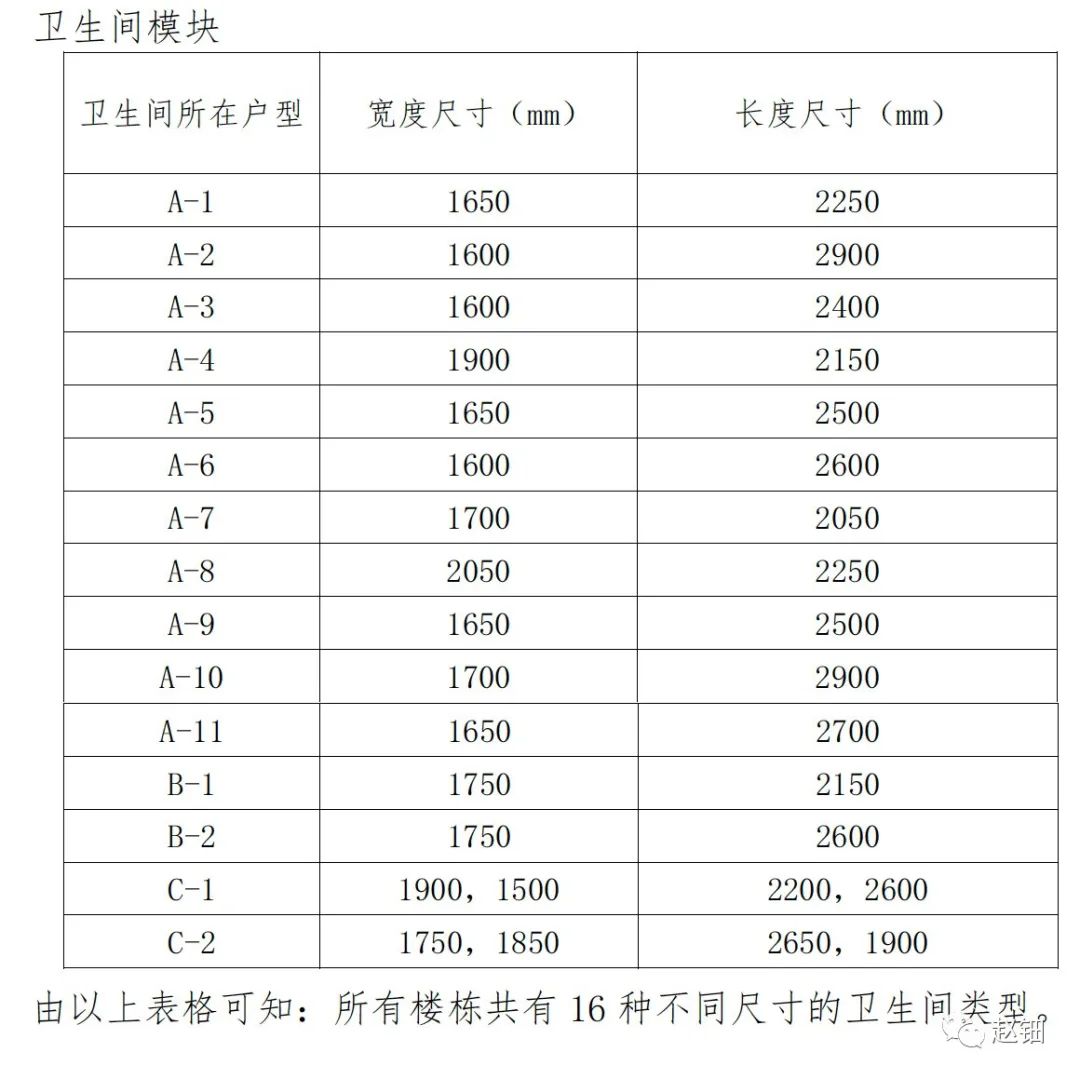

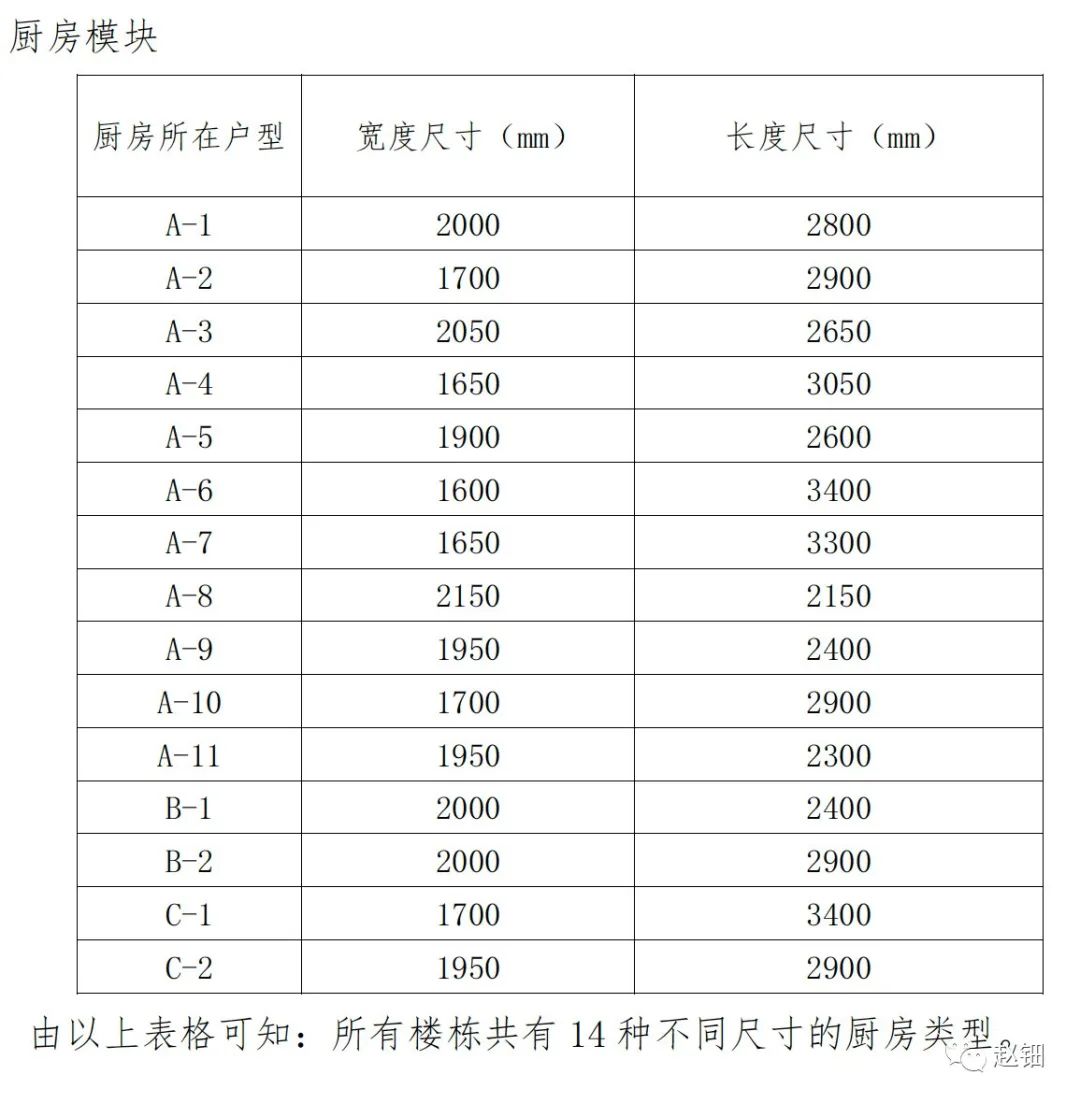

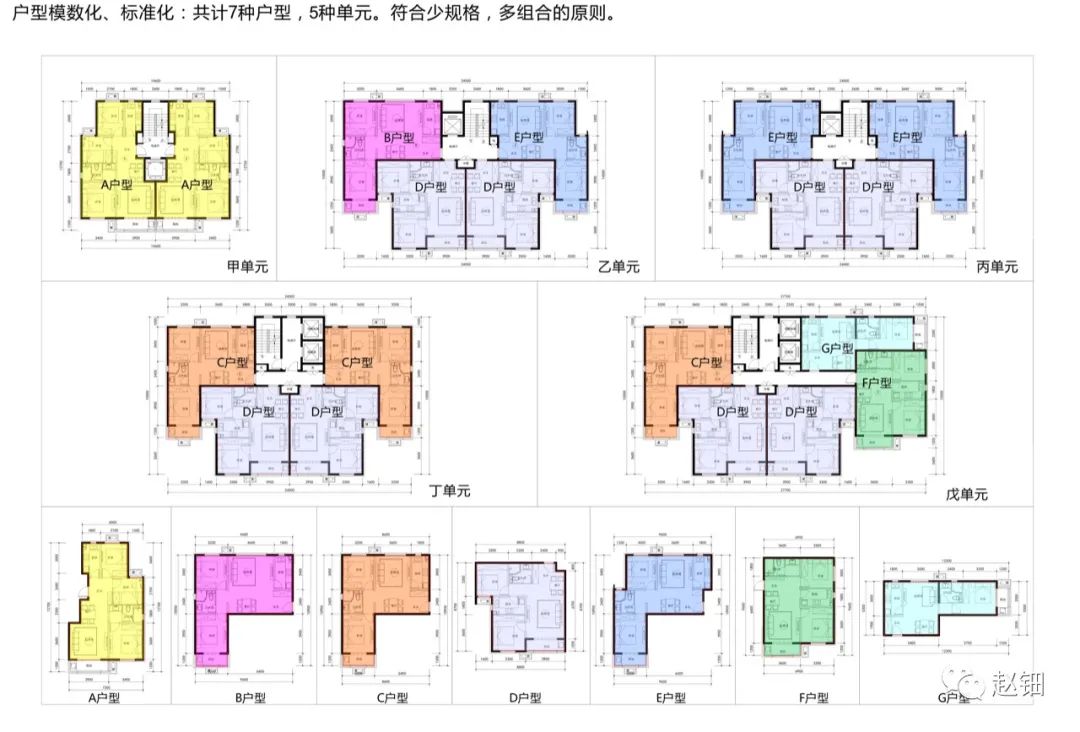

Figure 1 , general plan of a residential project a (8 residential buildings in total, 15 house types designed and 8 unit plans combined) Figure 2 , plan combination of house type A of a residential project (8 residential buildings, 15 house types designed and 8 unit plans combined) Figure 3 , statistical table of plane dimensions of kitchen a of a residential project (8 residential buildings in total, 15 house types designed and 14 kitchen plane dimensions) Fig.

4 statistical table of plane size of toilet a of a residential project (there are 8 residential buildings in total, 15 house types are designed, and there are 16 plane sizes of toilet).

Many projects still follow the traditional design methods, there is little communication among disciplines, and there is little consideration on the standardization of precast buildings in the design process.

The structural components are “split” only after the construction drawing design is completed; Such a design method is difficult to meet the requirements of standardization; There are many types and specifications of components in the “disassembled” parts department, resulting in complex design, poor rationality, low repetition rate in production, difficult amortization of mold cost and high cost increment.

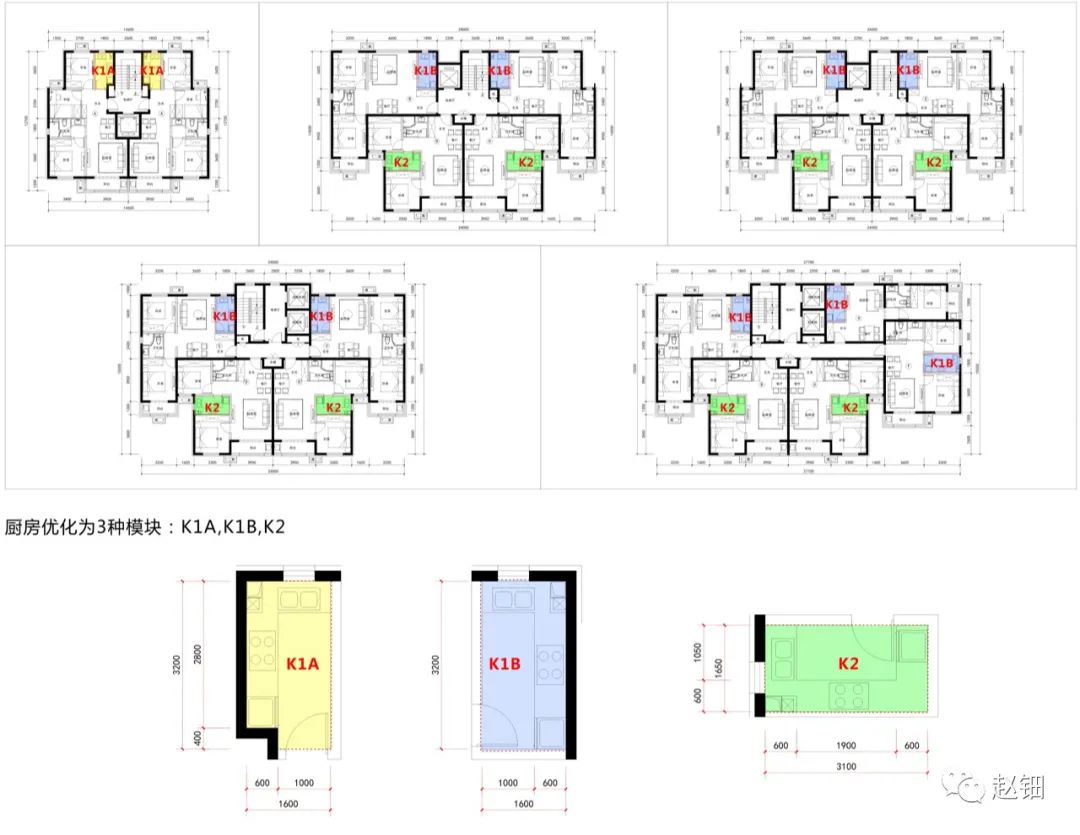

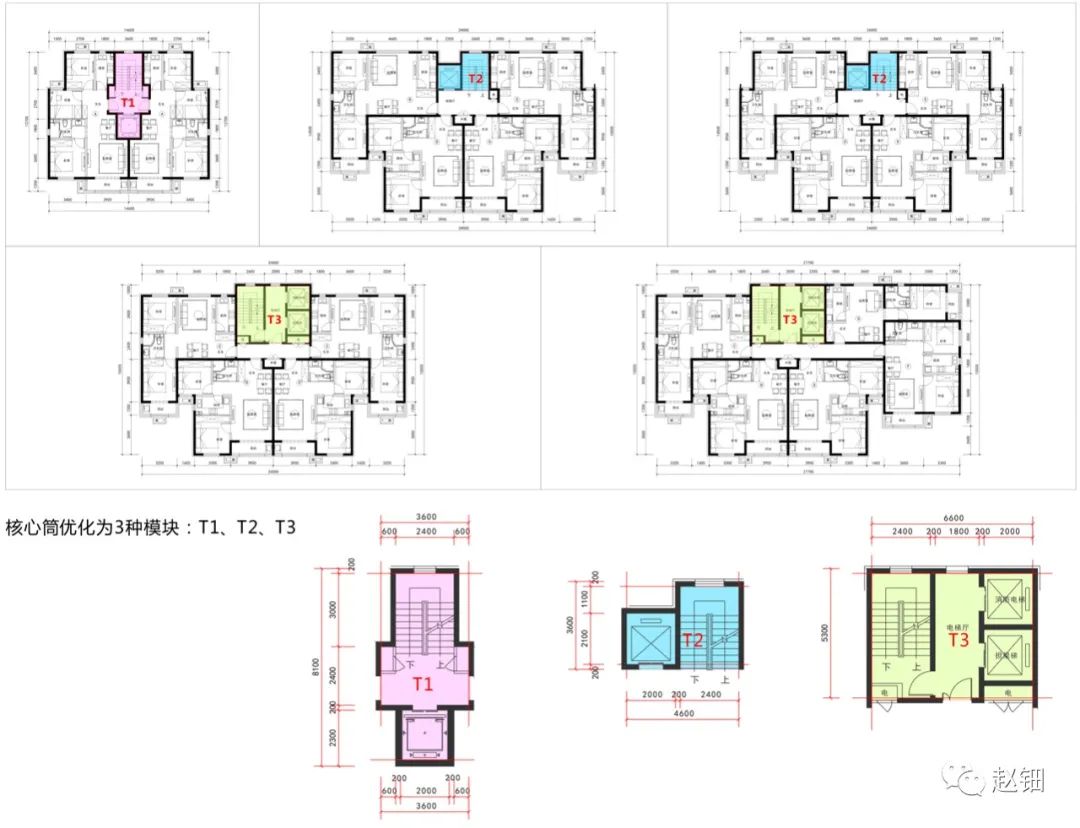

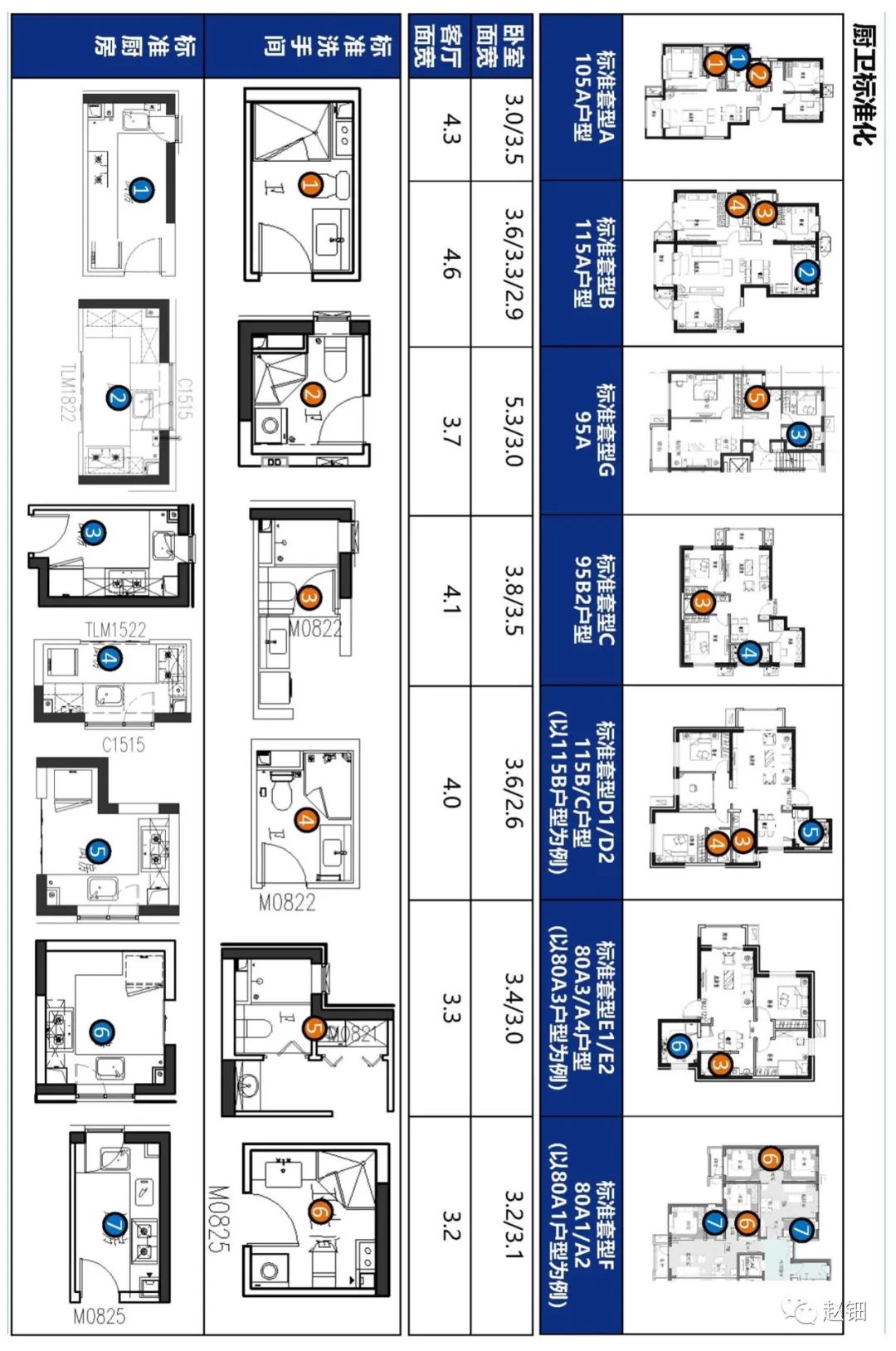

Figure 5.

List of kitchen and toilet types of a residential project B (although the house type standardization is good, there are still many types of kitchen and toilet, there are 7 kinds of kitchen and 6 kinds of toilet, which can still be simplified and optimized).

There are many projects.

Although they are designed according to the modulus requirements, they also carry out “design standardization” for buildings, units, building elevators, kitchen and bathroom, etc, However, the standardization degree of parts (components) has not been quantified, and there are still too many types and specifications of divided parts (components).

Figure 6 the standardized design of house type C of a residential project is better figure 7 the standardized design of kitchen C of a residential project is better figure 8 the standardized design of toilet C of a residential project is better figure 9 the standardized design of elevator lobby of building C of a residential project is better and the degree of standardization is low, which is a common phenomenon in current architectural design.

The current precast architectural design, because each project is different and does not realize the universal application of parts (components) across projects, the component manufacturers of all projects cannot produce in advance before receiving the detailed design drawings.

This causes a lot of waste of production capacity and can not increase effective supply when demand is tight, which is also an indirect reason for the high incremental cost of precast buildings.

The need for standardized design of precast buildings has long become the consensus of the construction industry.

However, the architectural design industry still has not formed a systematic consensus on standardized design theory, standardized design methods and how to evaluate standardized design.

2.

What is standardization? So, what is standardization? The current National Standard Guide to standardization Part 1: general terms for standardization and related activities (GB / t20000.1-2014) defines “standardization” in this way—— “In order to obtain the best order within the established scope, promote common benefits, establish common use and reuse provisions for practical or potential problems, and prepare, publish and apply documents.” There are two notes after the definition: (1) the terms established by standardization activities can form standardization documents, including standards and other standardization documents.

(2) The main benefits of standardization lie in improving the applicability of products, processes or services for the intended purpose, and promoting trade, exchange and technical cooperation.

What is the purpose of standardization? “Standardization can have one or more specific purposes to make products, processes or services suitable for their purposes.

These purposes may include, but are not limited to, variety control, availability, compatibility, interchangeability, health, safety, environmental protection, product protection, mutual understanding, economic performance and trade.

These purposes may overlap.” (GB / t20000.1-2014) standardization is an activity process of formulating standards, implementing standards and revising standards.

The purpose is to make products, processes or services applicable.

Standardization activity is an activity of establishing specifications.

[2] Standardization is not only limited to technology and parts, but also production equipment and processing process..