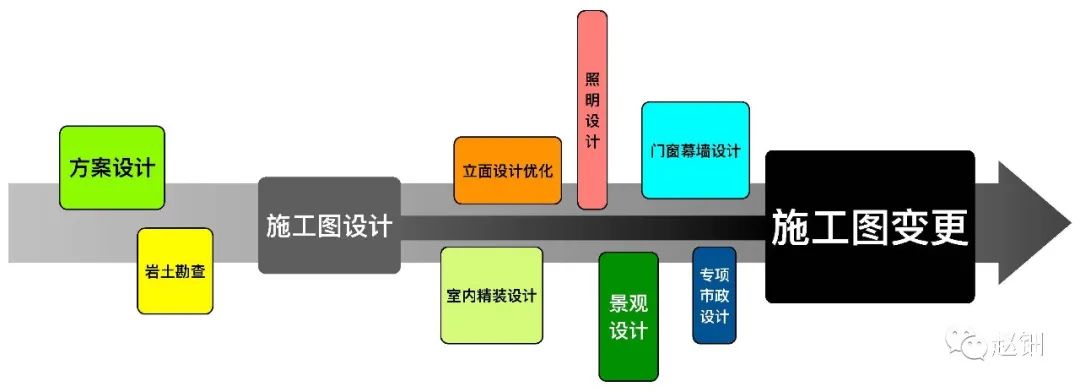

The previous “precast building | re discussion on Design Standardization (1)” puts forward that the low degree of design standardization is the number one problem restricting the development of precast building, defines what is “standardization” and discusses who is “standardization”.

Table of contents 1 The low degree of design standardization is the number one problem restricting the development of precast buildings.

2 What is standardization? 3.

For whom? Here, we will continue to discuss the forms of standardized methods.

4.

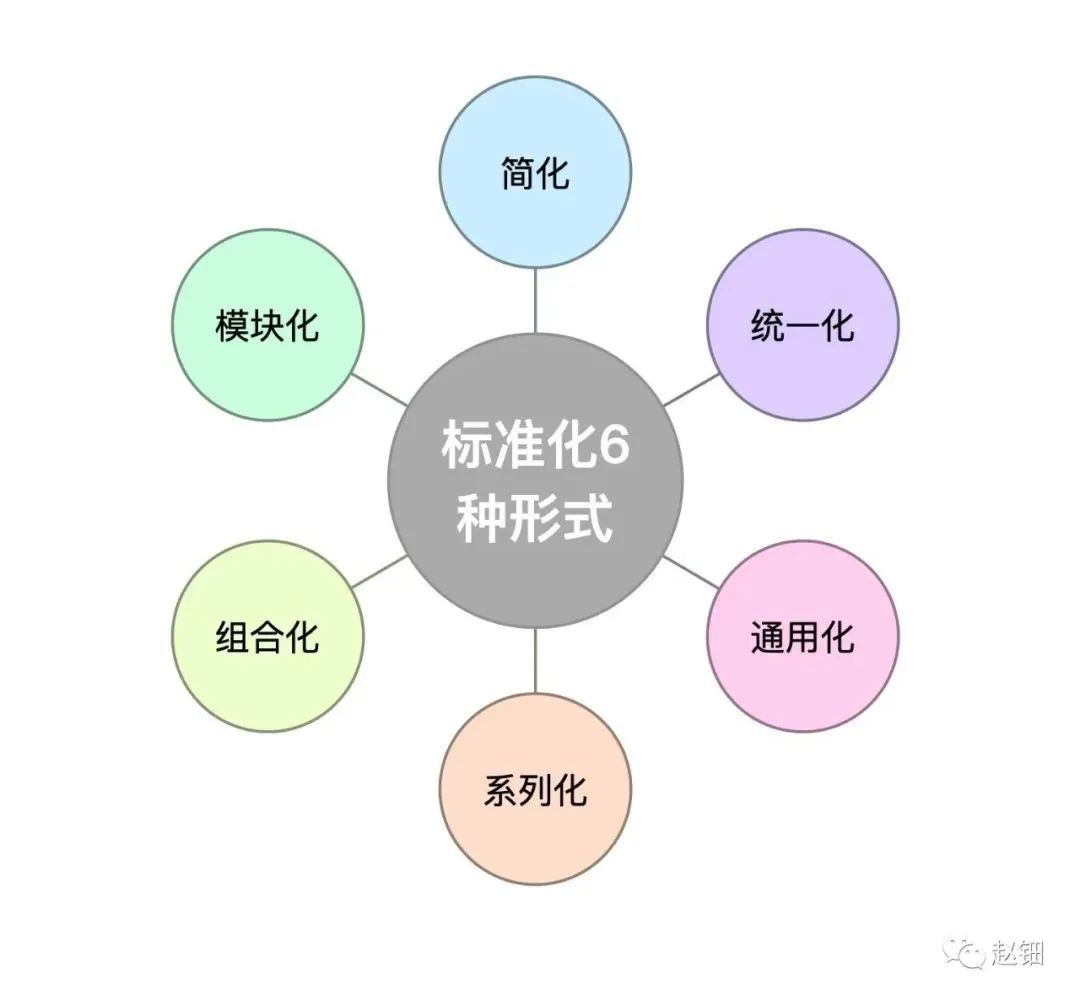

What are the forms of standardization? The most common standardization methods have six forms: simplification, unification, generalization, serialization, combination and modularization.

Figure 10.

6 forms of standardization 4.1 Simplification and unification simplification is the most common and basic standardization method.

Simplification, popularly speaking, is to simplify complex objects, that is, to simplify complex objects and summarize and merge similar or similar contents, so as to reduce the number of types and improve the proportion of the same objects.

The purpose of simplification is to control the type of object and prevent blind increase.

The simplified method is widely used in various scenarios.

Through simplification, inefficient and unnecessary design contents can be eliminated, and the design object can be more concise and reasonable, so as to improve the efficiency of design work and create conditions for improving the efficiency of subsequent production links.

Unification is to unify similar objects, merge them into one or several limited forms, eliminate different expressions of the same object, and make the form, function and other technical characteristics of the object consistent.

In the history of human science and technology, unified weights and measures, unified railway gauge, unified voltage and frequency are typical cases of unification.

In the design and production of precast buildings, the unified coding of parts (components) is an important unified work.

In fact, unification and simplification are often used together.

4.1.1.

Simplification and unification of residential house type plane some design cases with poor standardization, the first is that the simplification work is not done or not in place.

Recently, I saw a residential project D, which is similar to the residential project a mentioned in the above “precast building | re discussion on Design Standardization (1)”, and the scale is not large.

The aboveground area is less than 50000 square meters, and there are only 6 residential buildings.

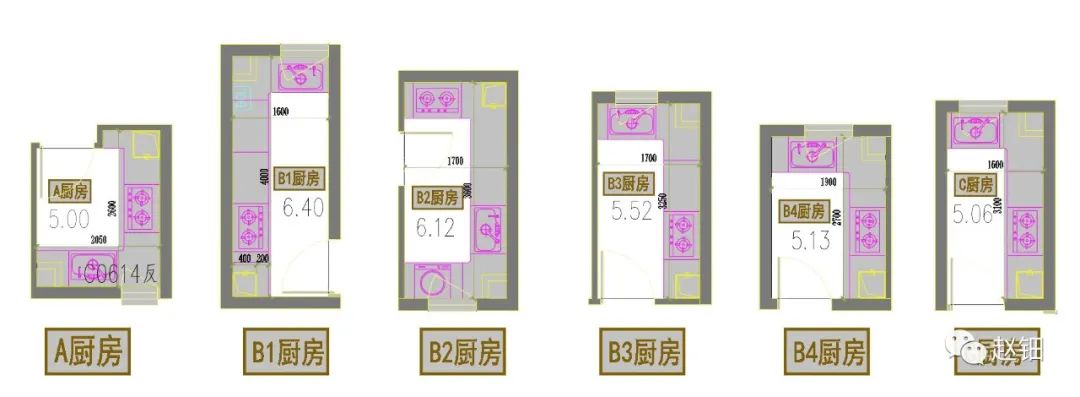

The house type standardization is OK, there are only 6 house types, but the degree of standardization of kitchen design is low.

The layout of B3, B4 and C kitchens is basically the same (FIG.

11), but the Bay and depth dimensions are slightly different, which can be merged and simplified to reduce unnecessary differences.

Figure 11 plan of D # 6 kitchens of a residential project (6 residential buildings, 6 house types and 6 kitchens are designed, of which the layout of B3, B4 and C kitchens are basically the same, and there is little difference in Bay and depth, which can be simplified and unified).

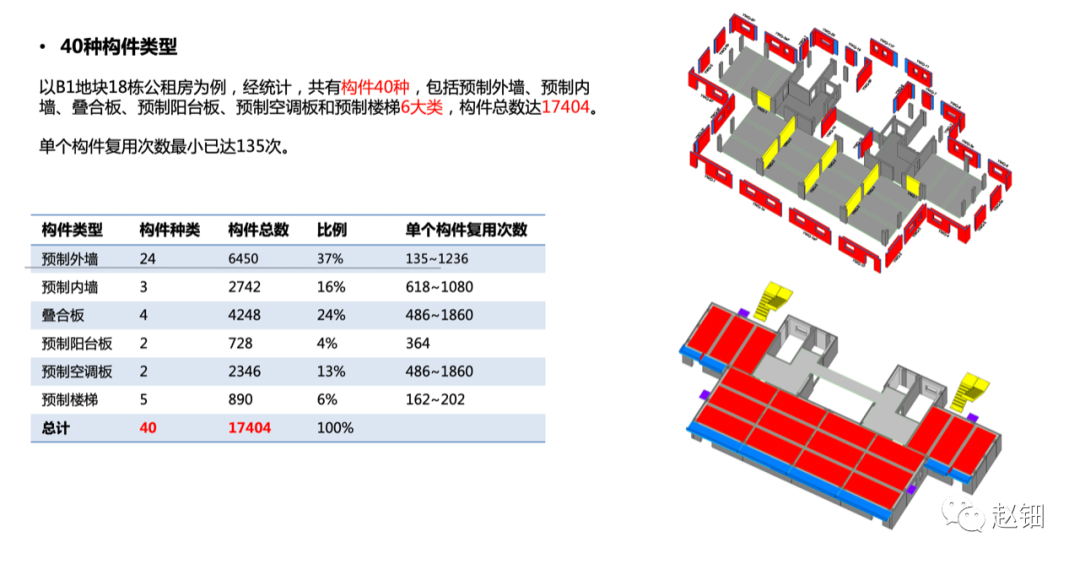

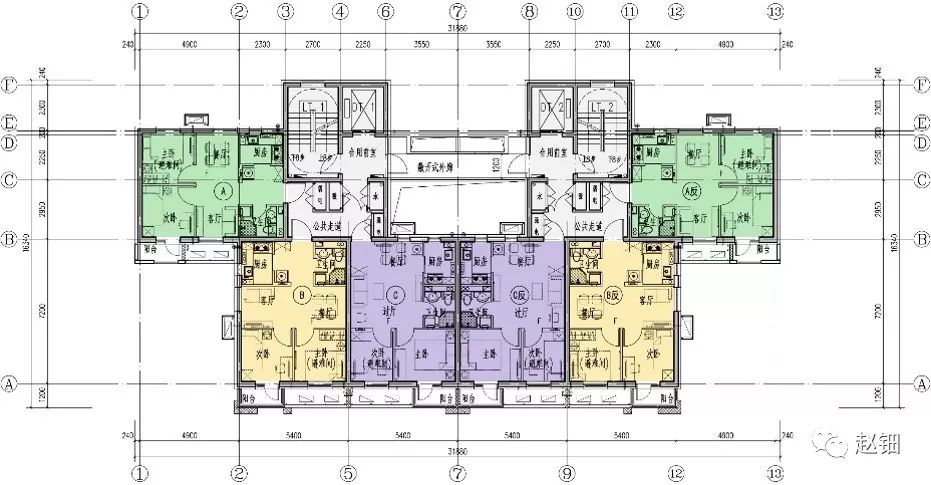

TongZhou Taihu public rental housing project (Figure 12) has a total area of more than 530000 square meters, a total of more than 5000 public rental houses, and the standardized design is very good.

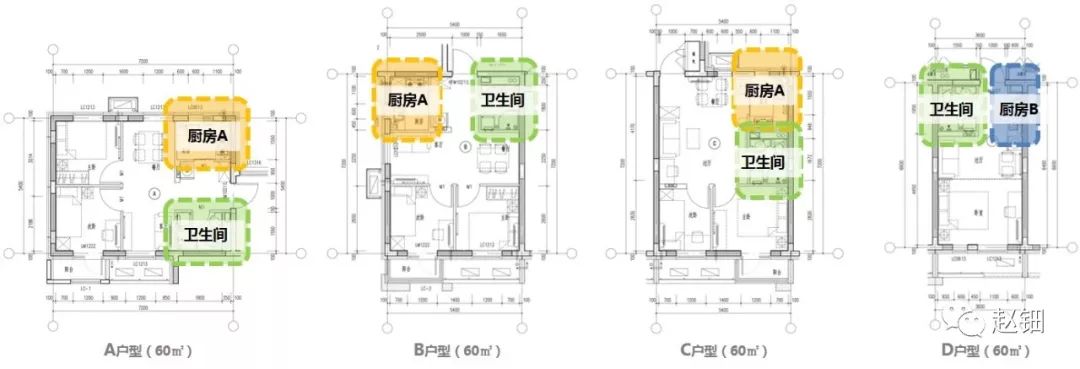

Through simplification and unification, all house types are unified to four house types, the kitchen is unified to two planes, the bathroom is unified to one plane, and the elevator room is unified to two planes (FIG.

13 ~ 16).

It can be said that the simplification and unification have been achieved to a high degree.

Figure 12 TongZhou Taihu public rental housing Figure 13 TongZhou Taihu public rental housing unit plane 1 (with a total construction area of about 530000 square meters, about 5000 sets of public rental housing, only 4 types, 2 kitchens, 1 bathroom and 2 traffic cores) Figure 14 TongZhou Taihu public rental housing unit plane 2 (with a total construction area of about 530000 square meters and more than 5000 sets of public rental houses, there are only four types of houses, two kitchens, one bathroom and two traffic cores) Figure 15.

TongZhou Taihu public rental house kitchen Toilet standard module (with a total construction area of about 530000 square meters, more than 5000 sets of public rental houses, only 4 types of households, 2 types of kitchens, 1 type of toilets and 2 types of traffic cores) Figure 16.

TongZhou Taihu public rental house traffic core 2 modules (with a total construction area of about 530000 square meters, more than 5000 sets of public rental houses, only 4 types of households, 2 types of kitchens, 1 type of toilets and 2 types of traffic cores) 4.1.2 The simplification and unification of precast components and the standardization of precast component design have a direct impact on production, construction and cost.

In the early stage of the development of precast buildings, due to lack of experience, simplification is often ignored or not done in place, resulting in more types of components in some projects.

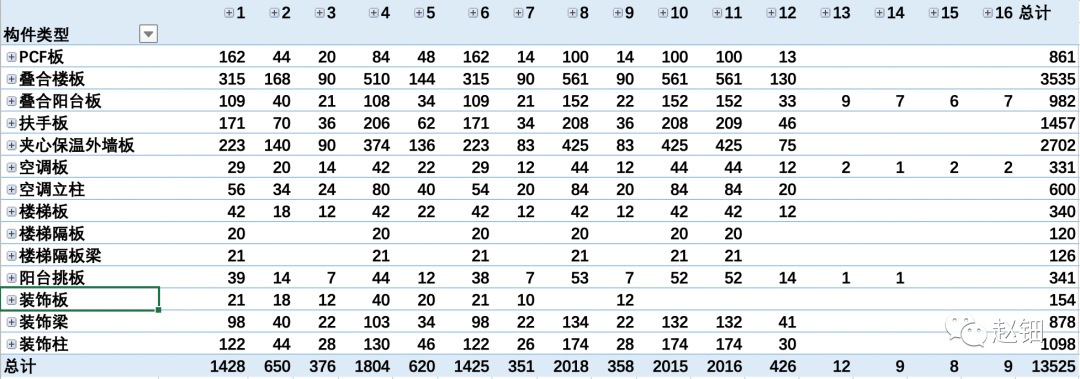

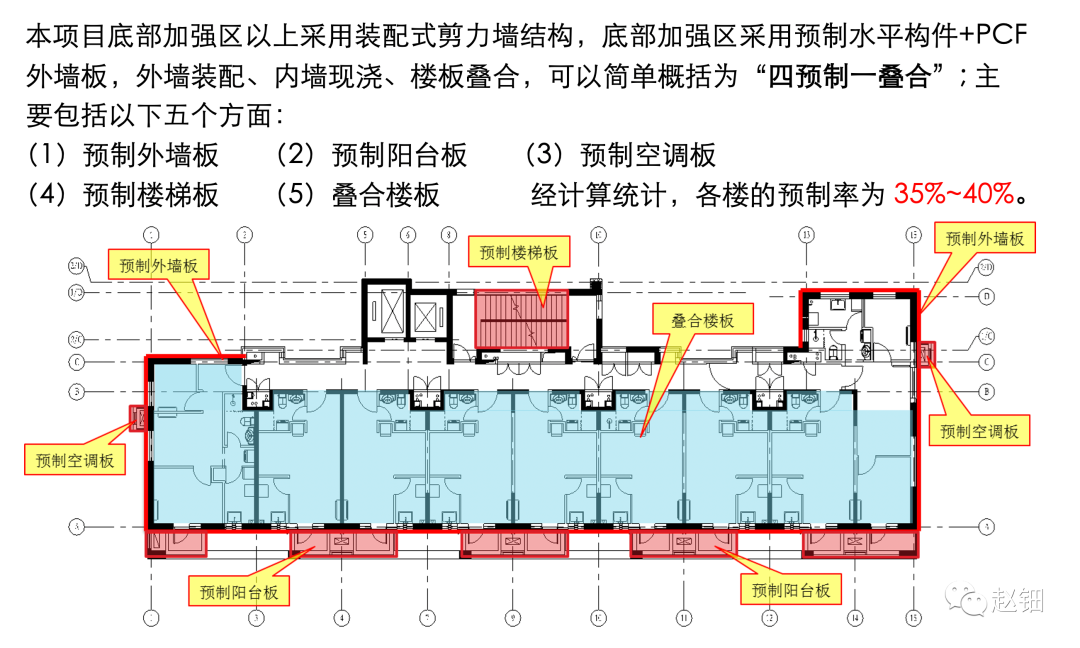

Guogongzhuang phase I public rental housing project has a total aboveground construction area of about 170000 square meters and provides more than 3000 sets of public rental housing (Figure 17).

The main structure of the residence adopts precast sandwich exterior wall, precast laminated floor slab, precast balcony plate, precast air conditioning plate, precast stair plate and other precast components.

The outer wall of the first and second floor reinforcement area adopts PCF plate with the same effect as the upper outer leaf plate (Fig.

18).

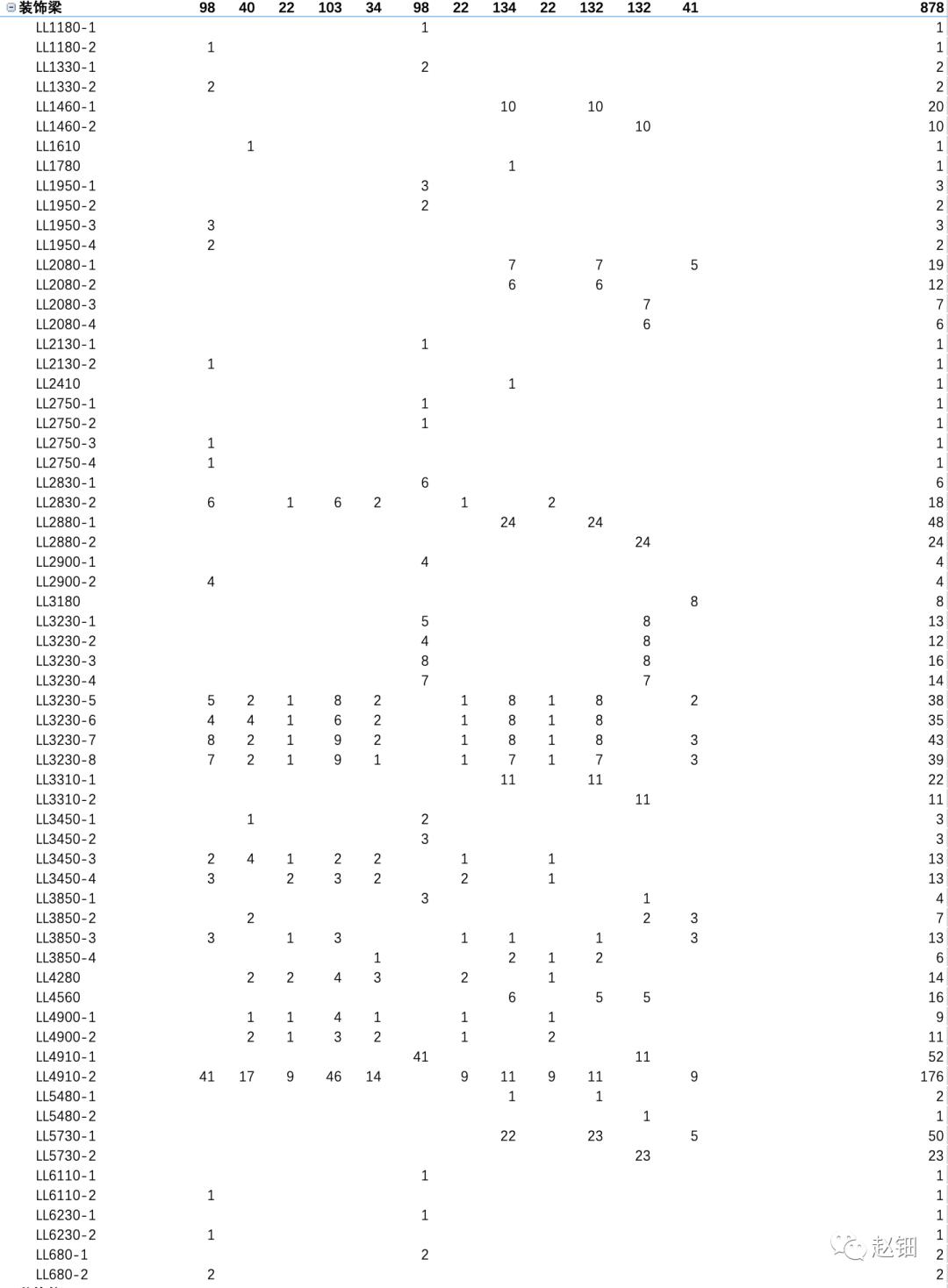

There are many kinds of components in this project (Table 1), and the repetition times of some decorative beam components are less than 10 (Table 2).

Because the type and quantity of components are not counted in the construction drawing stage, and simplification and unification are not paid attention to in the first half of the design, there are many types of precast components, the formwork amortization cost is high, and the overall cost increment of the project is also high..