Compared with the traditional pipe pile production mode, the automation degree of Guangdong structure production line has reached more than 95%.

Finally, Wu Xueqing, general manager of Foshan Power Construction, made a concluding speech.

After several days of commissioning preparation, the trial production and operation of the automatic production line basically achieved the expected purpose, and all production work was smoothly promoted.

First of all, he thanked the staff who have been fighting continuously in this project and praised their working spirit of racing against time and overcoming difficulties.

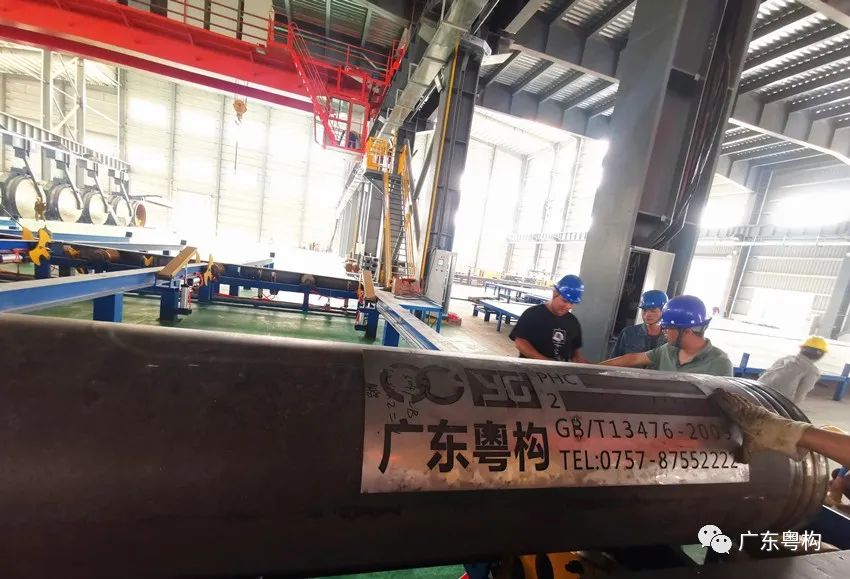

(the first PHC pipe pile of Guangdong Yuegou ▼) Zhang Jiechun, general manager of Guangdong Yuegou, made a commencement speech.

On the morning of April 7, 2022, the trial production of the automatic production line in the first workshop of Guangdong Guangdong structural pipe pile was successfully completed! This also marks the successful trial production of the first automatic production line of prestressed high-strength concrete pipe pile (PHC pipe pile for short) of Guangdong Yuegou new building materials industry Co., Ltd! In the morning of the same day, the component production center of our company organized the commissioning and acceptance of the automatic production line of pipe pile workshop 1.

He also said that the company will continue to increase the introduction of technical talents and R & D investment, continuously strengthen technological innovation and product quality, and give full play to the positive role of the R & D center to further promote the high-quality development of our pipe pile production.

According to Meng Dejiang, director of our component production center, the annual production capacity of PHC pipe piles reaches 6 million meters, and the main specifications are Ф 300~ Ф 800phc pipe pile.

It said that to truly realize the intellectualization and automation of the pipe pile production line, we can not simply replace the old equipment with advanced equipment, but organically combine and apply the optimization of production process, improvement of production process and improvement of production efficiency.

In the clean and tidy production workshop, modern automatic production equipment was arranged in order, and energetic workers operated the equipment in an orderly manner on the production line.

The main production equipment and technology are at the domestic leading level, with significant advantages: higher production efficiency, greater production capacity, more advanced technology, lower labor cost, and greatly reduce the labor intensity of operators.

The mixing system, distribution system, mold cleaning system, mold closing reinforcement processing system, centrifugal forming process system, thermal energy maintenance system, aggregate cleaning and feeding system have all realized full automation.

I hope you can work together to solve various problems existing in the production and operation in the future, so as to lay a solid foundation for the full production in the future.

Double Head Lifting Pin Anchor

This is a new challenge to the innovation and R & D of our production technology.

Wu Xueqing, deputy secretary of the Party committee and general manager of Foshan Power Construction Group Co., Ltd., Chen Yongbin, chairman, Chen Jinqing, vice chairman, Zhang Jiechun, general manager, Zhang Minjian, executive deputy general manager and relevant responsible persons of Guangdong Yuegou new building materials industry Co., Ltd.

If there is infringement, please contact to delete…

After the ceremony, the group visited and guided the production workshop.

Thank you very much for the concerted efforts of the company and the strong support of all sectors of society, which has injected sufficient strength into our trial production work.

Editor: Guangdong Yuegou new building materials industry Co., Ltd.

some pictures and texts of the general manager’s office are from the Internet.

attended the trial production ceremony.