Review of previous articles: structural seismic performance design 01: initial performance design structural seismic performance design 02: quantification of seismic force and damage degree at the micro level.

In article 02, we understand the measurement methods of damage degree at the macro and component levels.

It is natural to think that macro damage must be composed of micro material damage.

If we know the damage degree of each material point in each component of the structure, We can know its macro damage degree.

The left figure above shows the beam section damaged in the experiment.

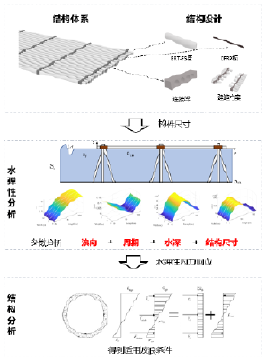

We first divide the beam into multiple small sections along the beam length, and then divide the section into multiple small grids as shown in the right figure above, so as to cut a beam into many small fibers.

In this way, the damage degree of the beam can be determined according to the number and degree of small fiber damage.

The above table specifies the quantitative standard of micro damage degree of materials, which is measured from the two levels of concrete and reinforcement respectively corresponding to different damage degrees.

When the damage degree is grade 1 ~ 3, the deformation degree of concrete is the peak compressive strain with the main compressive strain less than about 0.2%.

The deformation degree of reinforcement gradually increases from grade 1 to grade 3, and the deformation and damage of concrete under mild damage can not exceed 0.5%.

The damage degree of concrete can be determined from the peak strain of concrete, which is only 1.2 times higher than the damage index of concrete.

When the strain of reinforcement exceeds 1%, it reaches the level of serious damage due to excessive cracks in tension.

The reinforcement and concrete are bonded together.

From a long distance, it can be considered that there is no relative slip, and their strains are the same under tension and compression.

Since the compressive strain limit of concrete is much smaller than that of reinforcement (the peak strain is about 0.2% and the ultimate strain is about 0.33%), it can be judged only according to the compressive strain value of concrete; Concrete is allowed to crack in tension and does not control the tensile strain, so it can be judged only according to the tensile strain value of reinforcement.

In fact, the ductility of reinforcement is very good, and the bearing capacity will not be reduced when the strain reaches more than 10%.

Controlling the tensile strain of reinforcement is essentially to control the cracking degree of concrete.

After calculating the strain of each concrete fiber and reinforcement fiber of a beam, we can know the damage degree of the beam through comprehensive judgment, and then count the damage quantity and damage degree of all beams and columns to obtain the performance level and performance target grade of the overall structure.

So far, we have finished the damage discrimination methods at the macro, component and micro levels.

When judging the performance of the actual project, we can choose 1, 2 or 1, 3 combination, or 1, 2, 3 combination to judge.

The component level and micro level are realized by using software with different constitutive relations.

In article 01, we classify the importance of human organs from low to high into three categories: muscle, bone and organ.

Muscle plays the role of protecting bones and organs, but its own damage has no direct impact on maintaining life; Bones support the body and protect organs together with muscles.

After bone damage, organs will not be placed, which is more important than muscles; Organs play a direct role in maintaining vital signs, which is of the highest importance.

1.

In the building structure, energy dissipation components mainly refer to some horizontal components and special dampers, such as coupling beam, frame beam, buckling restrained brace, viscous damper, etc.

they do not affect the bearing of vertical load after failure, and they play the role of consuming seismic energy in the process of failure.

Their effect on the structure is equivalent to the fuse in the circuit, which not only protects the main structure, but also facilitates the maintenance after failure.

The following figure shows the schematic diagram and energy dissipation mechanism of the beam end forming the plastic hinge: in the left figure, the reinforcement at the crack of the plastic hinge at the beam end is repeatedly stretched and compressed with the reciprocating action of the earthquake, and the right figure shows the hysteretic curve of the reinforcement in this process, that is, the relationship curve between force and deformation under the reciprocating load.

The ordinate of the hysteretic curve is the force and the abscissa is the displacement.

The product of the force and displacement is the work done by the reinforcement.

When the reinforcement yields and enters the plastic section, the residual deformation will occur during unloading (the external force decreases), so that the reinforcement consumes part of the seismic energy.

The value of this energy consumption is equal to the area surrounded by the hysteretic curve and the x-axis.

The total energy input by an earthquake to the structure is roughly fixed.

The seismic energy can be consumed periodically through plastic hinges.

When the energy consumed by the structure per unit time is greater than the input energy, the kinetic energy becomes smaller and the structure gradually returns to rest, which is the principle of the action of energy consuming components.

To improve the energy dissipation capacity of energy dissipation members is to improve its ductility, that is, to extend the horizontal section of the hysteretic curve in the figure above, so that it can surround a larger area in a cycle.

For horizontal members, the height of the compression zone determines the elongation of the reinforcement.

The smaller the height of the compression zone, the greater the elongation of the reinforcement and the more energy it absorbs.

Increasing the reinforcement in the compression zone can reduce the height of the compression zone.

When the reinforcement in the tension compression zone is symmetrical, the height of the compression zone can be reduced to twice the thickness of the protective layer; Increasing the stirrup ratio can form the hoop effect, which can make the concrete form multiple longitudinal short columns under the action of large pressure.

The stirrup can effectively bind them together to avoid the compression instability of small short columns, so as to effectively increase the ultimate compressive strain and ultimate compressive stress of concrete.

Therefore, increasing the amount of longitudinal reinforcement in the compression area and increasing the stirrup ratio are the most effective methods to improve the ductility of beams.

When designing energy consuming components, because it is hoped that they will be destroyed first, the design internal force cannot be amplified.

Guangdong high standard even multiplies the internal force of energy consuming components by a reduction factor of 0.9, which is not only targeted to control the failure sequence, but also to protect other more important components.

Strong columns and weak beams are the concrete embodiment of this design concept..