The official account of the assembly building practitioners should be concerned about the public numbers.

Today is the seventh day of the first month.

I’m officially at work.

Good luck! A new year, a new journey, accompanied by zhuao.com on the long march ~ let’s move on to today’s topic: first, the scale of precast buildings is insufficient, and the loss in 2021 is expected to be 2.5-3.6 billion.

A few days ago, I saw a news on the finance and economics channel that on January 29, 2021, a listed company engaged in real estate development and precast construction issued an annual performance forecast for 2021, The expected performance changes from profit to loss.

During the reporting period, the net profit loss attributable to the shareholders of the listed company was 2.5 – 3.6 billion yuan, changing from profit to loss over the same period of the previous year; Note → according to the report, the main reason for the change of performance profit to loss is that the company’s cast construction business has not reached the corresponding business scale, and the operating loss is about 900 million yuan due to the impact of fixed expenses such as factory depreciation and capital cost; Affected by the development cycle of real estate projects, the settlement area and settlement income of real estate projects are less this year, resulting in an operating loss of about 400 million yuan in the current period of real estate business.

2、 The cost of precast construction is the lifeline of enterprises, and the prospect of precast technology that can save costs is bright.

In previous articles of zhuao.com, we have also shared many reasons for the rise of the cost of precast construction.

Compared with the traditional cast-in-situ concrete, the rise of the cost is related to the specific precast design scheme, prefabrication rate and assembly rate, which can not be generalized, However, the overall construction and installation cost has a growth rate of about 10-15% compared with the traditional cast-in-place.

In addition to the increase in cost, according to the special inspection results of dozens of precast buildings published by Shanghai and Beijing Construction Commission in their respective jurisdictions, there are still many problems in precast buildings.

Moreover, according to the precast projects I have inspected, the quality of precast projects is better than that of sleeve connection grouting, improper waterproof and leakage of precast external walls The design depth of precast shear wall and cast-in-situ section joints is insufficient and wrong, the insulation design of precast sandwich exterior wall is unreasonable, the insulation layer is discontinuous, resulting in condensation and peeling of cold bridge exterior wall, and so on.

1.

Then, someone asked: since the precast construction cost is high and the quality is not as good as expected, why should we do the precast construction? If you still have such questions, you can refer to the previous article of zhuao.com: an explanation: why should China develop precast buildings? 2.

What are the main crux of the rise in the cost of precast (PC)? You can refer to the previous articles of zhuao.com: the construction and installation cost of precast buildings is higher than that of cast-in-situ.

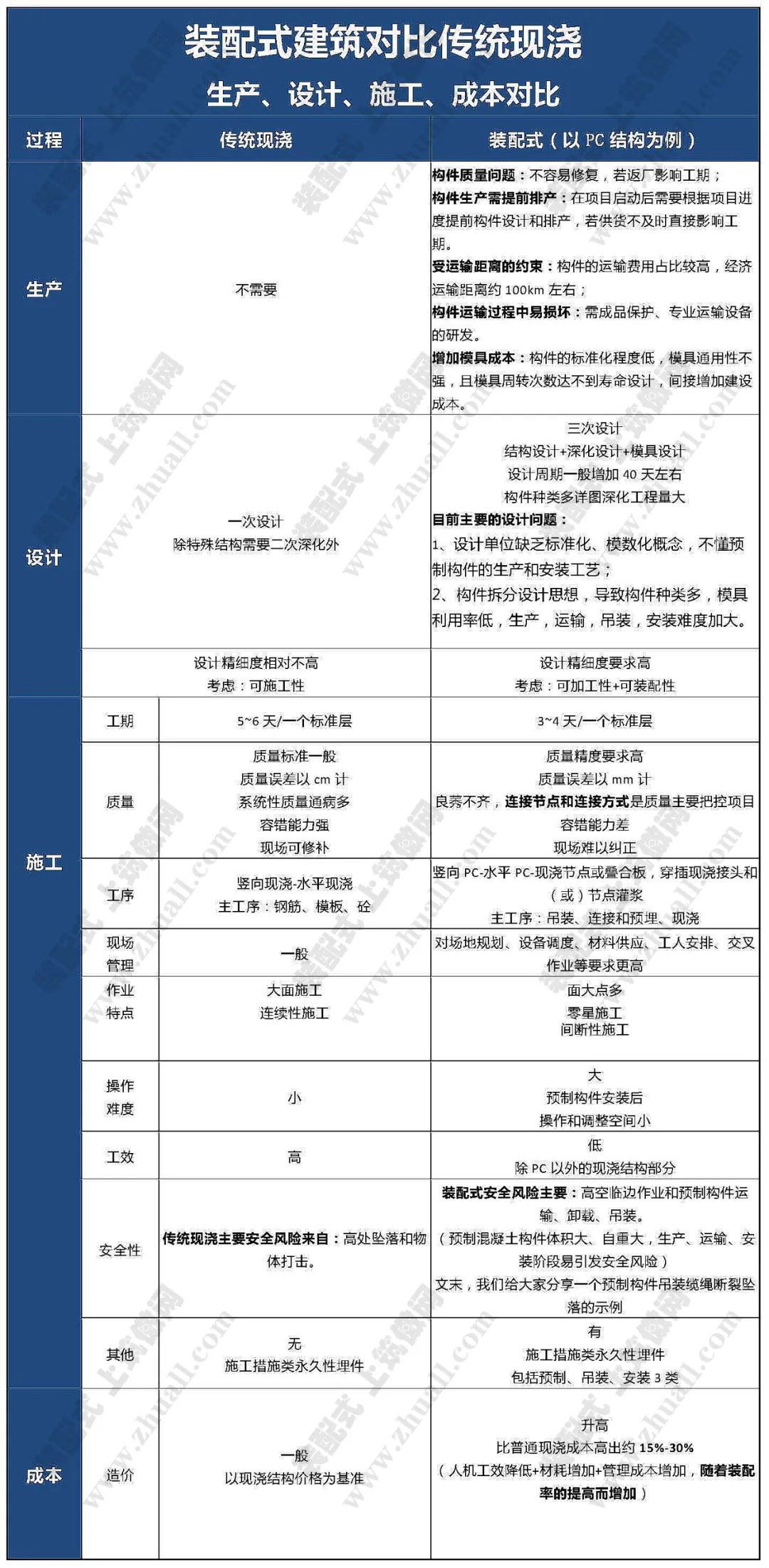

Where is the crux? We have also summarized the comparison table of precast building and traditional cast-in-place in production, design and construction cost before: ▲ precast building vs traditional cast-in-place in production, design, construction and cost comparison III.

trace the source of cost reduction of precast building, fill medicine according to prescription → standardization and scale of precast building Marketization # from the first part above, the reason for the huge loss announced in the financial report of a listed company is the insufficient scale of assembled projects, as well as production depreciation and operating expenses.

The increment of construction and installation cost of precast buildings is mainly reflected in component production, component transportation and component construction and installation.

The rise of this cost should be regarded as the superficial embodiment of the increase of construction cost.

From the development history of precast buildings in China, it is not difficult to see that precast buildings in China are still in the primary stage.

For the implementation subjects of precast projects, whether from developers, design institutes, general contracting units, supervision units, component factories, deepening design units, main material suppliers and other participating units, they are still in the exploratory stage, In other words, the “two pulse of Ren and Du” of the whole industrial chain of precast buildings has not been opened up.

For the control units of many precast projects, the cost contract principals of developers still maintain the cost awareness of precast projects in the stage of strictly controlling the “steel consumption” (i.e.

limiting the concrete and steel content indicators in a single square meter in the contract), and the degree of integration is low.

Modular building standardization: the most important thing in building industrialization is design standardization, and the most fundamental to realize design standardization is modular coordination, that is, dimensional coordination.

Standardization actually includes design, production and engineering construction.

The purpose is to solve the connection between the standardized design of precast buildings and the application of standardized components and parts; Implement the design of “less specifications and more combinations”, guide the transformation of customized and small-scale production mode to standardization and socialization by clarifying the specific dimensions of general standardized components and parts, and guide the component factory, design institute and construction unit to carry out “modular coordination” on the common dimensions of components and parts, Modularization is carried out in each stage according to the regulations, so that there are fewer types of components, and the production molds, transportation and installation will be unified, so as to fundamentally improve the production, design and construction efficiency, so as to reduce the cost.

Large scale of precast buildings: the components of precast buildings are relatively special, and at present, most of the popular household allocation of developers in local projects are non standardized, which is related to the demand of buyers and consumer groups..