3D printing technology can easily and quickly manufacture components with complex geometry.

It has been widely used in aerospace, automobile, biomedicine and other fields.

Due to the printing mode of layer by layer deposition, the printing interval between adjacent layers is long.

When depositing the next layer of wire, the upper layer of wire has cooled, resulting in a low degree of wire entanglement on the interlayer interface of the formed component.

The strength of interlaminar interface is much lower than that of wire and interlaminar interface, and the formed components show high anisotropy in mechanical properties as a whole.

When printing large components, the printing time between layers is further increased, which is particularly prominent.

In order to reduce the anisotropic defects in the mechanical properties of printing materials, there are a lot of discussions on how to improve the interlayer bonding strength in the deposition process.

Andrzejnycz team of Oak Ridge National Laboratory successfully improved the interlayer bonding strength of carbon fiber reinforced ABS materials through infrared heating.

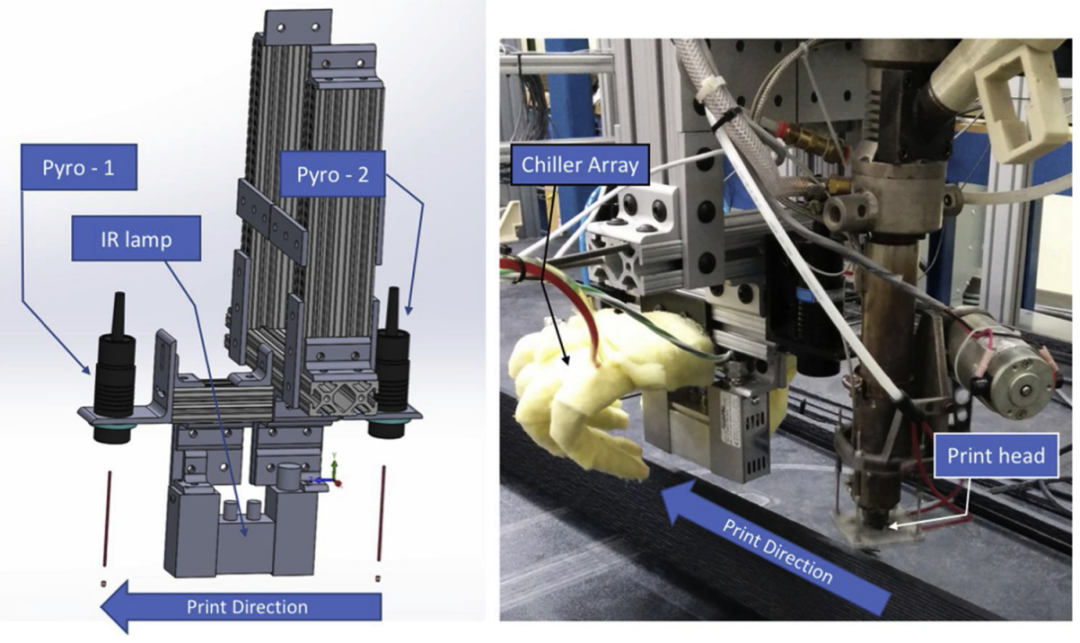

Firstly, the researchers developed a set of infrared heating device for the large-area additive manufacturing system.

The device is installed in front of the nozzle (as shown in Figure 1).

Its function principle is to preheat the cooled deposited layer surface before the nozzle extrudes the next layer of material, so as to improve the interlayer bonding quality.

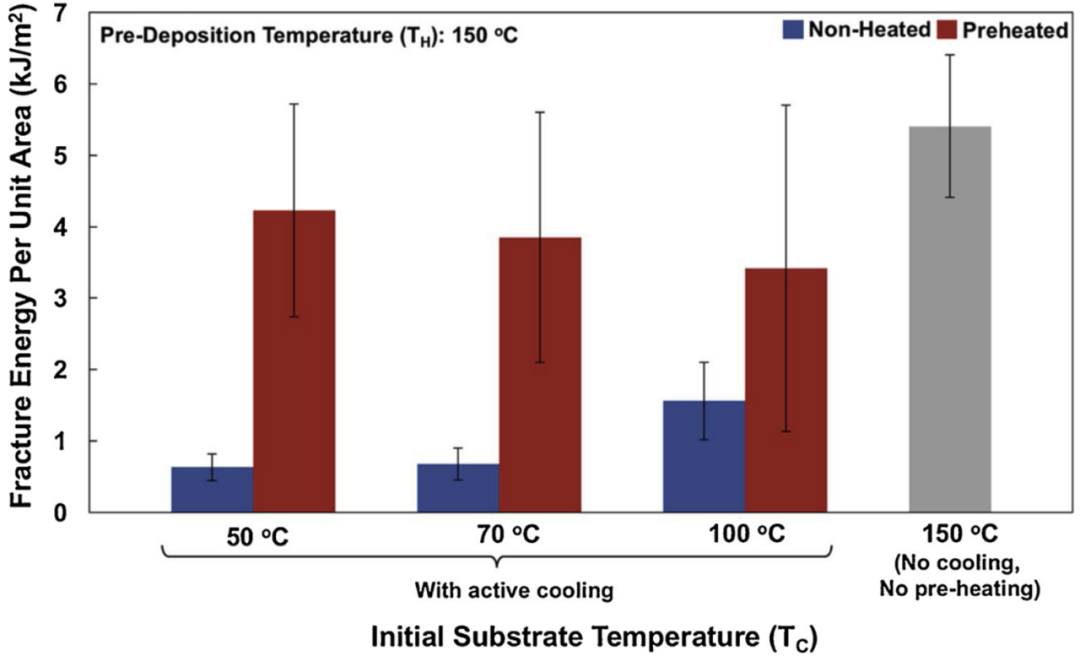

In order to discuss the effect of preheating at different initial substrate temperatures (TC), the researchers kept the preheating temperature (th=150 ° C) unchanged and set TC in the range of 50 ° C to 150 ° C for printing.

In addition, keeping TC (150 ° C) unchanged, th in the range of 150 ° C to 220 ° C was set to discuss the effect of preheating temperature on interlayer bonding quality.

In order to determine the interlaminar tensile strength and fracture toughness, tensile and double cantilever experiments were carried out on the printing materials under each working condition.

The experimental results show that after infrared preheating of the significantly cooled bottom layer (TC = 50 ° C), the interlaminar tensile strength and interlaminar fracture toughness of the printed component are doubled compared with those without preheating (as shown in Figure 2), which shows that infrared heating can effectively improve the interlaminar bonding quality of large components with very long interlaminar interval.

When the initial bottom layer temperature is high, continuous preheating has no significant effect on the interlayer bonding quality (Fig.

3).

Only when the temperature is too high (220 ° C), the interlayer fracture toughness decreases to a certain extent due to polymer degradation.

This paper shows an effective method to improve the bonding quality between layers of 3D printing materials, which is of great significance to reduce the anisotropy of mechanical properties of large printing components.

From the perspective of 3D printing ambient temperature, this study uses infrared heating to regulate the temperature of deposition layer, but the fixed infrared device can only preheat in one direction.

In actual printing, the extrusion path of nozzle is often complex, which requires a wider range of temperature regulation, which can be improved in future research.

In the printing process of large components, not only the strength of the interlayer interface is affected, but also the combination of the interlayer interface will experience a long interval.

The influence of the change of ambient temperature on the interlayer interface should also be clarified.

Fig.

1 infrared heating design of the printing system Fig.

2 keep the preheating temperature unchanged and the fracture energy of different initial bottom layer temperatures Fig.

3 the initial bottom layer temperature unchanged and the fracture energy of different preheating temperatures.

This research paper is published in additional manufacturing under the title of “controlling substratetemperature with frared heating to improve mechanical properties of large-scale printed parts”.

Full text link: 10.1016/j.addma 2020.101068。.