▲ Click the card above to follow the “Prefabricated Building Network” Source: Haitian Electromechanical Technology China Concrete and Cement Products Association (CCPA) Prefabricated Concrete Member Branch Vice Chairman Unit | Haitian Electromechanical Technology Co., Ltd.

Dezhou Haitian Electromechanical Technology Co., Ltd.

and its predecessor, founded in 1997, is the leading enterprise in the domestic “assembled building intelligent equipment” industry, and the enterprise with the most complete product lines in the industry.

In 2020, the company identified its brand as “the pioneer of PC+smart equipment super factory”, and defined the development plan for listing within five years.

The company is in the new green building industry, aiming to promote the industrialization of new buildings.

The 13th Five Year Plan clearly proposed the requirements for the development of prefabricated buildings: the national average assembly rate will reach 15% in 2020, and 30% in 2025 (more than 70% in developed countries in Europe and America) 。 According to the requirements of national strategic development, it is estimated that the scale of China’s prefabricated construction equipment industry will reach 100 billion yuan in 2025, with strong sustainability in the future.

The company is the vice chairman unit of the Precast Concrete Components Branch of China Concrete and Cement Products Association (CCPA), the vice chairman unit of the Concrete Products Machinery Branch of China Construction Machinery Industry Association, the vice chairman unit of the Light Aggregate and Light Aggregate Concrete Branch of China Concrete and Cement Products Association, the specialized and new small giant enterprise of the Ministry of Industry and Information Technology of China, the gazelle enterprise of Shandong Province, the prefabricated building industry base of Shandong Province Provincial fabricated building intelligent equipment engineering laboratory, provincial enterprise technology center and provincial “invisible champion” enterprise.

The company is the first enterprise in the industry to introduce European technologies and standards in Asia.

As early as 2008, it set up the “Haitian European Intelligent Equipment Research Center” in Italy, which was led by four foreign experts.

At present, the company has three major production and research bases in Dezhou, Ningjin and Xuchang.

At the same time, it has established an industry university research partnership with China Academy of Building Sciences, China Metallurgical Construction Research Institute, School of Architecture of Tsinghua University, Shandong University, Xi’an University of Architecture and Technology, and jointly established “Intelligent Equipment Control Institute”, “Innovation Technology Institute”, “Prestressing Technology Institute”, and “Green Building Materials Institute”.

The company is the only unit in the industry to undertake the national 13th Five Year Major R&D Program; Participated in the compilation of more than 10 national building standards; It has 114 patents, including 40 inventions and 74 utility models.

Industry leading products and cases 1.

Relying on years of cooperation experience with Italian expert team and advanced European technology, the production line of sliding multi-functional prestressed components has successfully created the first domestic production line of sliding multi-functional prestressed components with one machine and multiple uses after years of research, development and practice.

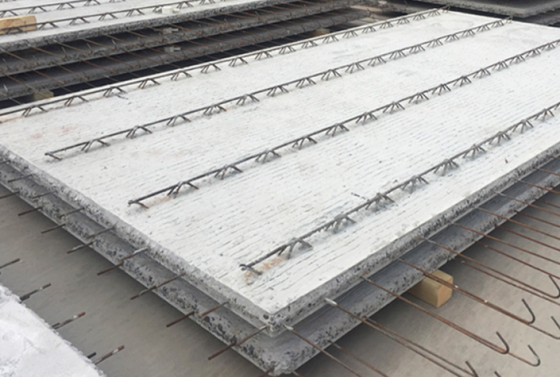

It can produce prestressed composite slabs, prestressed hollow slabs and prestressed beams at the same time.

The production line covers a number of national invention patent products, including sliding multi-function pre-stressed member forming machine, multi-function cutting machine, film covering and roughening integrated machine and gantry distribution machine.

The production line equipment is manufactured in strict accordance with European standards, and the products reach the international leading level.

The case shows the production line site of sliding multi-functional prestressed components for Sichuan customers; the production line site of sliding multi-functional prestressed components for Chongqing customers; the production line site of sliding multi-functional prestressed components for Hebei customers; the production line site of multifunctional prestressed prefabricated components for Liaoning customers; the production line site of sliding multi-functional prestressed components for Malaysia customers; the production line site of sliding multi-functional prestressed components for Uzbekistan customers; the production line site of sliding multi-functional prestressed components for Uzbekistan customers 2.

Prestressed long line platform production line Haitian prestressed long line platform production line combines European long line platform technology with the current situation of domestic components, and successfully realizes the production of prestressed composite slabs, prestressed composite beams, non prestressed composite slabs, interior and exterior walls and other prefabricated components.

The production line is composed of gantry spreader, prestressed tensioning system, automatic feeder, cleaning and spraying joist, automatic vibrator, film covering and roughening machine, production platform, maintenance system and other equipment.

High degree of automation (automatic operation of equipment), high utilization rate of formwork (up to 70%), and high production efficiency (single shift composite plate components of daily production ≥ 60m ³)、 It has the advantages of diversified production, small floor area, low investment cost and low labor consumption.

The case shows the production line site of prestressed long line platform for Shandong customers The production line site of prestressed long line platform for Sichuan customers The production line site of prestressed long line platform for Jiangsu customers The production line site components and application of prestressed long line platform for Shandong customers, Its product advantages mainly include the following points: First, the mold supports the tensioning force through its own structural strength, reducing the investment cost of the tensioning pedestal.

2、 The rib height, width and length of double T plates are adjustable; The same set of mold can produce double T-plate products with different spans and sizes, realizing multiple uses of the first mock examination.

Sectional design, according to the customer’s site conditions, can be freely combined into any length of mold for production.

3、 There is no need to make a high cost foundation, and the component production is flexible and efficient.

The mold can be quickly disassembled and assembled to the next construction site, reducing the transportation cost of components.

4、 The product can be used independently, or it can be combined with tensioning system, cloth distribution system, maintenance system to form a complete production line.

The case shows that the Shanghai customer prestressed double T plate production line site components and application company adheres to the business philosophy of “being an enterprise trusted by customers”, and keeps in mind the enterprise mission of “creating value for customers with intelligent manufacturing”.

It has not only won customers’ praise with its products, but also won the mutual long-term cooperation and development with its services..