On December 25, China Railway 22nd Bureau Group Construction Component Co., Ltd.

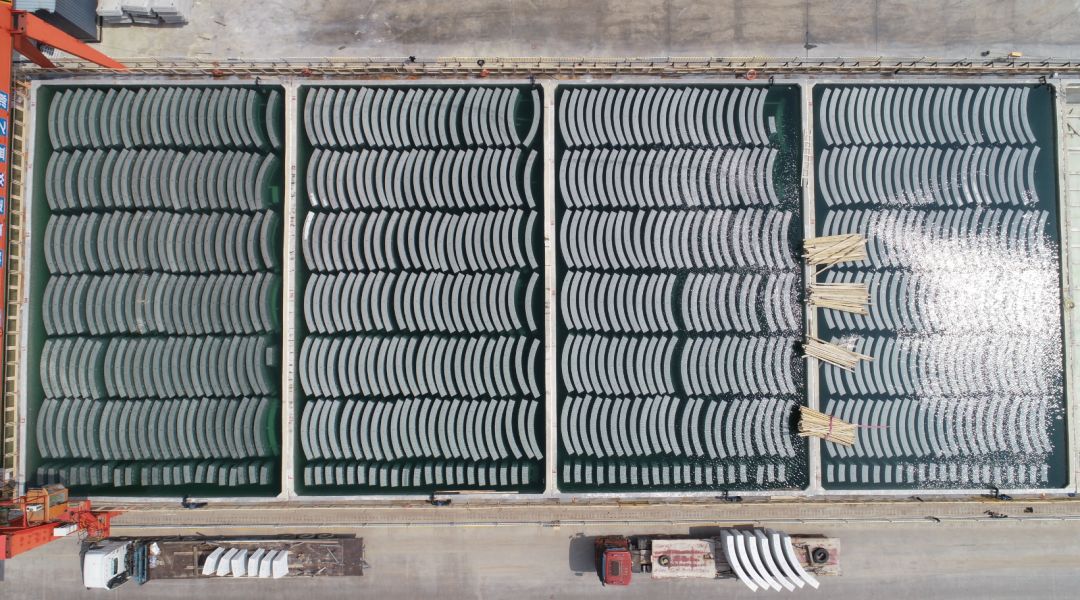

(hereinafter referred to as the component company) successfully broke through the 2000 ring pass in monthly production on the premise of ensuring safety and quality, which is another new milestone in monthly production since the establishment of the component company.

The production of 2000 rings of 8.5 m diameter segments means that about 13000 tons of cement, 1250 tons of fly ash, 150 tons of water-reducing agent, 1100 tons of mineral powder, 23000 tons of river sand, 38000 tons of crushed stone, and 6800 tons of reinforcement are required.

The use of steel alone is equivalent to the construction of an Eiffel Tower.

In the middle of November, Han Zhen, the deputy general manager of the company, Guo Jianbo, the first-level project manager, Sun Minjun, the director of the safety and quality department, Zhang Li, the deputy director of the science and technology department, and other relevant leaders reorganized the production, safety, quality and other aspects of the component company and put forward a series of rectification suggestions.

In December, in accordance with the deployment and arrangement proposed by the company’s working group, the component company, in the face of the shortage of cement resources and the tight supply of ground materials, planned ahead and worked together to overcome many difficulties to provide continuous power for segment production, creating a new record of 8.5 meters of segment production in Guangzhou.

During December, the daily average production of segments of the component company reached 67 rings, 14 rings higher than that of November.

How can such a yield be achieved? In terms of process and method, the test personnel of the segment factory optimize the concrete mix proportion to ensure that the concrete performance is good during the period affected by cement, and at the same time, the two-shift shift takes turns to control to prevent the unstable concrete performance from causing a decline in output; The technical personnel improved the pouring and vibration technology and adopted mechanical vibration.

Compared with the original pouring and vibration technology, this technology can shorten the working time to 6 minutes and improve the efficiency of segment production; The mechanical maintenance personnel shall strengthen the equipment inspection and maintenance, reduce the equipment failure rate to the minimum, and ensure the continuous and efficient production of segments.

In terms of personnel, the leading group of the segment factory regularly held special production meetings with the labor service principals, and increased the corresponding measures such as daily assessment and incentive, so as to fully mobilize the enthusiasm of workers.

At the same time, strengthen the education and training of new and old workers, carry out a series of quality improvement activities such as standard publicity and implementation, benchmarking, exchange meetings, and third-party testing, improve the quality awareness of all staff, and ensure the stability of the quality of the safekeeping film while increasing production.

At present, the company’s two workshops, four assembly lines and eight segment production teams have been in place, with sufficient and stable personnel.

In terms of working methods, departments actively interact and react quickly.

All business departments went deep into the front-line workshops, strengthened communication and coordination, and made every effort to ensure the production of segments.

Compared with the past, the cumbersome communication process has been abandoned and the idea of “finding problems and solving problems at the first time” has penetrated into everyone.

It has strengthened the team awareness, service awareness and organization and coordination ability of all members of the component company, laying a solid foundation for meeting greater challenges in the future.

As of December 25 this year, the component company has produced 15713 segments of Guangzhou Metro Line 18 and Line 22, completed 54.36% of the output of signed contracts, and shipped 11376 segments in total.

At the same time, the component company also serves the construction of the new inter-city rail transit project in the Pearl River Delta, and undertakes the tasks of partial segment production and concrete supply of the inter-city Pazhou branch line in the Pearl River Delta.

At present, the component company has passed the acceptance of the trial production conditions of the Pazhou branch line segment and produced 10 8.8-meter segments.

The year 2019 has come to an end, and the new year is coming.

All members of the component company will work together to work hard in personnel, materials, equipment, safety, quality and other aspects, forge ahead, and continue to strive for the company’s reputation and efficiency.

Text: Wang Yun Picture: Gui Tianqi Editor: Gui Tianqi Editor in Chief: Song Qiang WeChat: China Railway 22nd Bureau Group Rail Engineering Co., Ltd., innovative development, cohesion, unity of knowledge and practice, and perfection.

.