In construction projects, before pouring concrete components, it is necessary to make a model that matches the shape and size specified in the design drawings. The material used to enclose the model is the template. There are many specifications for construction templates, but the types of templates are only wood templates, steel templates, aluminum templates, plastic templates, large templates, etc. Below, we will provide a detailed introduction to the types and characteristics of building templates..

1. Building formwork is a temporary support structure made according to design requirements, which forms concrete structures and components according to specified positions and geometric dimensions, maintains their correct positions, and bears the weight of the building formwork and external loads acting on it. The purpose of template engineering is to ensure the quality and safety of concrete engineering, accelerate construction progress, and reduce project costs..

2. The building formwork structure used in the construction of cast-in-place concrete structures mainly consists of three parts: panels, support structures, and connectors. The panel is a load-bearing plate that directly contacts the newly poured concrete; The supporting structure is a temporary structure that supports the panels, concrete, and construction loads, ensuring that the building formwork structure is firmly combined without deformation or damage; A connector is a component that connects a panel to a supporting structure as a whole..

1. Building formwork is the shell and support formed by concrete pouring, which can be divided into steel formwork, aluminum formwork, wood formwork, plastic formwork, large formwork, etc..

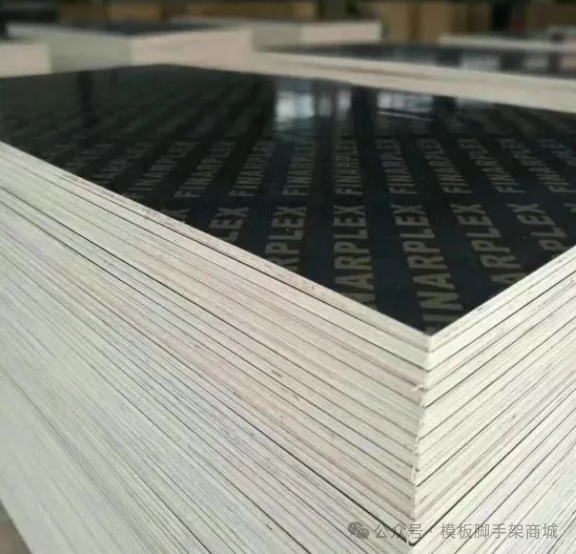

2. Building wooden formwork can be divided into building wooden plywood, laminated board, multi-layer board, double-sided adhesive, double-sided laminated building formwork, etc. according to the properties of the materials..

3. Building formwork can be divided into cast-in-place concrete formwork, pre assembled formwork, large formwork, and elevated formwork according to construction process conditions..

1. The main specifications of building wooden formwork include: 915X1830mm, 1220x2440mm, 1250x2500mm, etc. General building wood formwork specifications: 1220 * 2440, also known as large red board; 1830 * 915, also known as small red board, is commonly used and can be customized for special specifications..

2. Thickness of building wooden formwork: 9mm, 12mm, 15mm, 18mm, 21mm, 24mm.

3. Materials of building wood formwork: poplar, pine, eucalyptus, birch, hardwood, mixed wood, etc..

4. Types of building wood template adhesives: phenolic adhesive, melamine adhesive, urine adhesive, etc..

5. Architectural wood template film paper: Teal brown film, domestic brown film, black film, etc..

1. The construction template has a large area and a smooth surface, which not only reduces a lot of workload and shortens the construction time during construction, but also eliminates the need for too many workers to carry out formwork support, pouring, dismantling and other construction operations. Even the cost of decorating the exposed surface of concrete and grinding edges and joints is saved, saving a lot of cost..

2. It has a large bearing capacity and can withstand the pressure of pouring construction and the lateral pressure of concrete. The surface has been coated with film, making it smooth and wear-resistant, and can be reused multiple times..

3. A lightweight and thick base, made of multi-layer plywood with a thickness of over ten millimeters, for building formwork. The weight per unit area is only 50 kilograms. One or two construction workers can easily move building templates without the need for mechanical assistance, thereby saving costs. Moreover, storage and use are much more convenient than steel building templates. Template width.