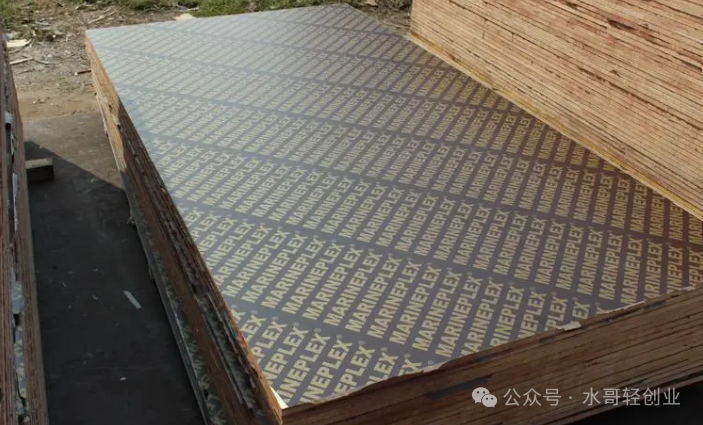

Hello everyone, today Shuige wants to talk about the wholesale of construction templates, which is a business opportunity filled industry. With the prosperity of the construction industry, we have seen a significant increase in demand for building templates, and many visionary entrepreneurs want to venture into this field..

So, what are the profits of this industry? Is it worth investing in? Next, Shuige will analyze each one for you..

The production process of building templates is not actually complicated, mainly including the development and design of aluminum profiles, mold matching, sawing and cutting, punching, welding correction, and pre assembly steps..

In this process, templates are finely divided into various types such as wall templates, floor templates, corner templates, and staircase templates to meet different building needs..

The mold matching process is a technical task, just like playing a puzzle game. It is necessary to use existing aluminum templates of various specifications to assemble the design according to the architectural drawings..

This link is very crucial as it directly affects subsequent production and assembly..

Different people have different assembly methods for the same building blueprint. We need to choose the one with the least number of templates, low processing difficulty, lowest cost, and simple and convenient assembly from various formwork schemes..

This approach can make as much use of standard templates as possible and reduce the use of special templates, as standard templates have relatively lower processing difficulty, faster assembly speed, and a higher possibility of subsequent reuse..

Cutting and punching are key steps in the production process. Aluminum templates need to be easily assembled and disassembled between different combinations, with a flat surface and tight seams..

This places high demands on the cutting size. When L>1800mm, the allowable range of error is 0~-1.5mm; When L ≤ 1800mm, the error range is 0~-1.0mm..

In addition, the cutting shape should be regular, and the cutting surface should be neat and free of burrs. At the same time, the accuracy of locking hole punching between templates is also crucial, which directly affects the smooth installation and installation speed..

Welding and calibration are also important production processes. Aluminum templates require a large number of end plates and reinforcing ribs for welding. Argon arc welding is a commonly used welding method with the characteristics of large welding volume and high requirements..

Full welding or intermittent welding (depending on the length of the edge) can be used during welding. The weld seam should be smooth and uniform, without defects such as porosity, welding penetration, cracks, undercutting, virtual welding, and missed welding..

At the same time, pay attention to the welding sequence and control welding deformation. Aluminum templates require a high level of flatness on the board surface, and during the welding process, deformation can only be controlled as much as possible but cannot be eliminated..

Only through correction can the flatness of the template be restored, ensuring the final flat effect of assembly. During the calibration process, special attention should be paid not to damage the surface of the template..

Finally, there is the template labeling and pre assembly process. When thousands of aluminum templates are stacked together, how to quickly identify their purpose and purpose relies entirely on labeling..

Pre assembly can detect problems in production in advance, thereby improving production efficiency..

Overall, the wholesale business of building templates has considerable profit margins and development prospects..

But successfully running this business is not easy, and it requires attention to various factors such as market dynamics, product quality, cost control, and customer relationships..

Only by continuously improving oneself.