Collecting practical cases of precast building demonstration cities (model cities) and industrial bases, promoting the industrialization of new buildings represented by precast buildings, and walking out of a new road of building industrialization with high scientific and technological content, good economic benefits, low resource consumption, less environmental pollution and full play of human resource advantages is the solution to the problem that China’s construction industry has been large but not strong for a long time Weak industrial foundation, low level of industrial chain coordination, fragmentation of industrial organization, extensive and backward construction methods and other prominent problems are the inevitable choice.

In November 2017, the Ministry of housing and urban rural development announced the first batch of 30 precast building demonstration cities and 195 industrial bases; In November 2018, in order to sort out the successful experience, analyze the existing problems, seek truth from facts and develop precast buildings according to local conditions, the Ministry of housing and urban rural development issued a notice and decided to evaluate the implementation of the first batch of precast building demonstration cities and industrial bases.

Cities and enterprises that passed the evaluation will continue to be recognized as demonstration cities and industrial bases, For cities and enterprises that fail to pass the assessment, the Ministry of housing and urban rural development shall revoke the recognition of demonstration cities and industrial bases; In September 2020, the Ministry of housing and urban rural development announced the second batch of 18 precast building model cities and 133 industrial bases.

Since the issuance and implementation of the guidance of the general office of the State Council on vigorously developing precast buildings (GBF [2016] No.

71) in 2016, China’s precast buildings have been promoted rapidly during the 13th Five Year Plan period, and the construction level and quality have been significantly improved.

However, compared with the requirements of developed countries and China’s green development, there are still great gaps and deficiencies.

In the “14th five year plan”, how to fully implement the new development concept of precast buildings, drive the comprehensive transformation and upgrading of the construction industry through the combination of “industry, University, research and application”, build a “built in China” brand with international competitiveness, and form the core competitiveness and first mover advantage of the enterprise has attracted the attention of all parties.

In order to explore the combination of “production, study, research and application” in the development of precast buildings, the group went to A26 architectural decoration Co., Ltd.

(hereinafter referred to as “A26”), China Academy of Architectural Sciences, Fujian Architectural Design Institute Co., Ltd.

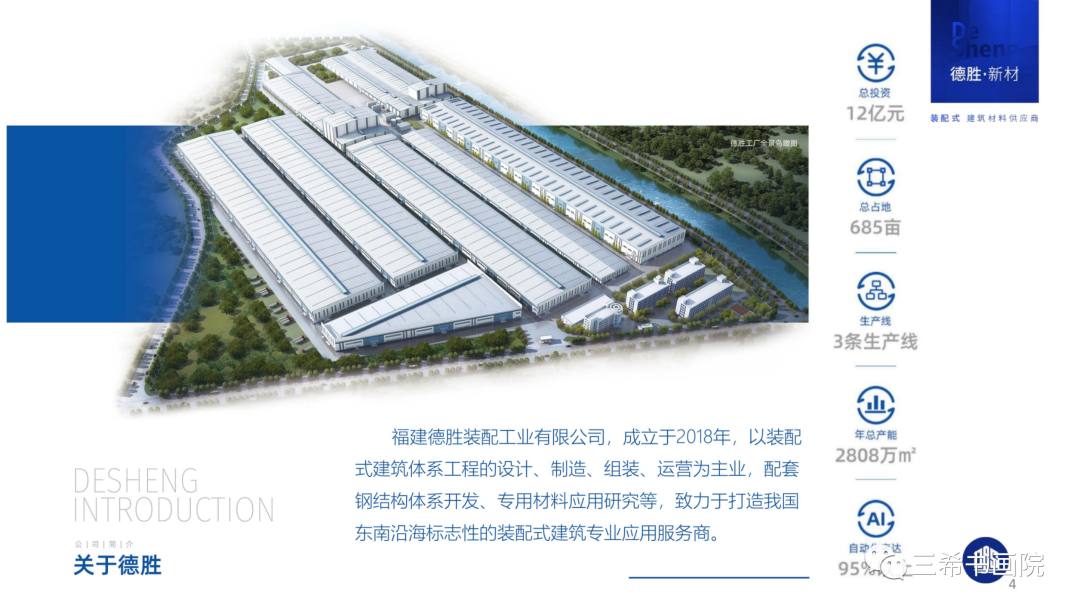

(hereinafter referred to as “Provincial Institute”), Fujian Academy of Architectural Sciences and Fujian Institute of precast buildings, Desheng precast construction industry base (hereinafter referred to as “Desheng”) carried out in-depth strategic cooperation planning and combined the practice of “industry, University, research and application” in the field of precast construction.

A26 will not be absent from the assembly construction track.

As early as 2013, A26 building put forward the concept of “factory production and assembly construction” in Hangzhou; In October 2015, A26 assembly R & D center was officially established.

Sinotech Hongde low carbon building (Hangzhou) R & D base is a joint venture between our A26 construction company Hongfeng Industrial Group Co., Ltd.

and China Construction Technology Group Co., Ltd., the largest holding subsidiary of China Academy of Building Sciences.

The total investment of the R & D base is 500 million yuan, and the first phase is planned to invest 100 million yuan.

Following the successful conclusion of the signing, unveiling and foundation laying ceremony between our company and China Academy of Building Sciences on November 1, 2015, our company has injected 80 million capital into this project.

On February 3, 2014, the production base was fully started, with a construction area of about 15000 square meters.

So far, the plant has been installed and entered the stage of equipment installation and commissioning.

According to the production capacity target planning of China Academy of Building Sciences, the R & D base will mainly develop a low-carbon building structure system integrating light steel and light concrete structure system, ground energy heat pump system technology, solar energy comprehensive utilization technology, energy-saving door and window technology and other low-carbon and green technologies.

The production capacity of low-carbon building structure with an annual output of 1 million square meters will be formed immediately, and the sales revenue will exceed 10 billion yuan.

At the same time, in the future, it will also become an important base for R & D, manufacturing, sales and training of production technicians of new equipment for low-carbon building system.

For A26, 2020 is a particularly critical year.

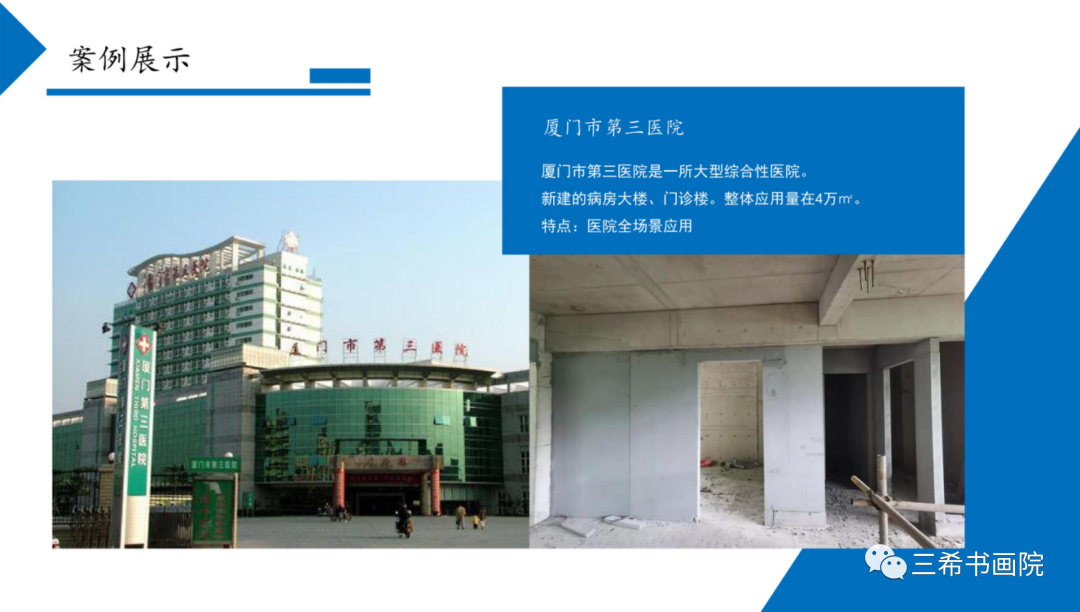

This year, changxiangrui Assembly Technology Co., Ltd., a subsidiary focusing on the integration of design and construction of precast interior decoration and full platform service, was officially established, marking the full development of A26 in the field of precast architecture.

At present, the company has established a new four-dimensional digital assembly system, and built a management system covering the whole life cycle of the project in terms of standardized design, industrial production, component assembly and digital integrated operation.

In the research and development of assembly technology, A26 has made some achievements.

It is reported that A26 adopts the dual track driving mode of independent originality and joint research and development, and integrates the traditional advantage projects of the company such as BIM Technology.

By the end of 2020, the company has applied for a number of assembly patents and edited 16 provincial and industrial standards (assembly interior decoration).

In order to strengthen the combination of “production, study, research and application”, A26 cooperated with Fuzhou University and Fuda architectural design and Research Institute where the headquarters is located as early as 2014 to jointly establish the “architectural assembly Research Institute of Fuzhou University” and explore a new mode of modern school enterprise cooperation in training design talents.

In January this year, A26 announced a strategic cooperation with the technology and industrialization development center.

The two sides will cooperate in the construction of Internet platform for assembly decoration industry, the establishment and scientific research of assembly decoration standards and specifications and major scientific research projects, the co construction of assembly decoration industry research cooperation platform, and the innovation and display of assembly decoration products.

Chen Min, vice president of A26, once said that the company has always paid attention to innovation and development.

In order to accelerate the high-quality development of assembly decoration, first, make every effort to increase technological innovation, technological integration and technological sharing; Second, carry out in-depth foresight on the market to realize rapid, reproducible and high-quality coverage of multiple product lines; Third, we are committed to improving the professional and in-depth service of the whole industrial chain..