>>>Taking the indoor electrical design of a fine decorated residence as an example, this paper introduces the design method of reducing the embedded electrical junction box in the precast concrete structure by using the internal distributor products and the technology of wireless control of indoor lighting lamps.

Key words: precast building , power distributor , wireless control lighting , precast concrete components , laminated floor > > > Introduction: the country is vigorously promoting the industrialized construction industry, and local governments are actively implementing it to increase the construction and development of pre supported precast buildings.

At present, the industrialization rate of civil engineering of precast buildings is gradually increasing, but the system integration of pipelines has not been followed up synchronously.

It is basically maintained at the original construction process level or less considered by the design unit.

The connection between factory prefabrication and on-site embedding is easy to make mistakes, which hinders the development of precast buildings to a certain extent, The number and location of embedded pipes and embedded junction boxes in precast PC components are prone to problems, and the problem of pipeline system integration needs to be studied and solved as soon as possible.

Taking the indoor electrical design of a fine decorated residence as an example, this paper introduces the design method of reducing the embedded electrical pipeline in the precast concrete structure by using the internal distributor products and the technology of wireless control of indoor lighting lamps.

1 current situation of electrical wiring in precast buildings precast concrete structure buildings, some internal and external wall panels, stair slabs and laminated floors are precast concrete components.

The structural components of the laminated floor slab are divided into two parts: industrialized prefabrication and on-site pouring.

The electrical equipment installed on the top of the household, such as the lighting lamp cap box, the reserved box for infrared curtain, the reserved box for indoor unit power supply of central air conditioner, the reserved box for fresh air fan power supply, etc., are set in the laminated floor slab and shall be reserved and embedded during the production of precast components.

At present, the electrical wiring principles of most residential indoor cast buildings are as follows: 1) the lighting lamp cap box, infrared curtain reservation box, central air conditioning indoor unit power reservation box and fresh air fan power reservation box installed on the laminated floor shall be embedded with deep junction box and connecting pipe at the corresponding position, and the junction box in the precast component shall be reserved and embedded at the time of component production.

The electrical pipeline led out from the junction box is laid on site in the cast-in-situ layer of the laminated floor slab.

2) The horizontal pipelines in the cast-in-situ layer of the composite floor slab shall be reasonably arranged to avoid the intersection of three layers.

Although the above electrical pipeline laying principles can deal with the intersection between lighting and socket pipelines to a certain extent, in residential households with fine decoration design, in recent years, some electrical manufacturers have developed a distributor product, which is used to reduce the design method of embedded electrical pipelines in precast concrete structures through the technology of wireless control of indoor lighting lamps.

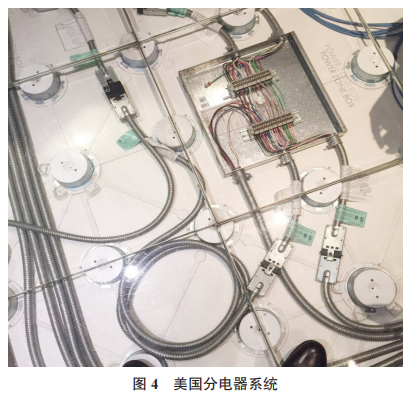

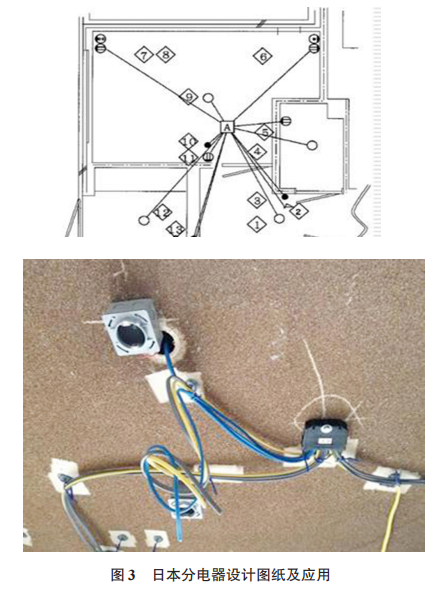

2 Introduction to distributor products 1) foreign development: the precedent of adopting such electrical products in Japan, Europe and the United States and other countries: such products are adopted abroad to realize the integrated control of indoor lighting.

In recent years, some domestic electrical manufacturers have developed such new distributor products in combination with foreign experience.

2) Domestic distributor products: in recent years, some electrical manufacturers have developed a distributor product, which is an integrated product of strong and weak current.

It is installed in the ceiling of finely decorated residential buildings.

It is connected by the ~ 220V power supply of indoor mains power, and the branch circuit is led radially to each lamp control circuit in each room.

Each lamp control circuit is connected with the distributor by wireless switch, Wirelessly control each lighting control loop.

Lighting distributor products are integrated wireless control.

The indoor lighting circuit is integrated, which can simply realize complex circuits such as double control and multi control, and realize intelligent memory switch.

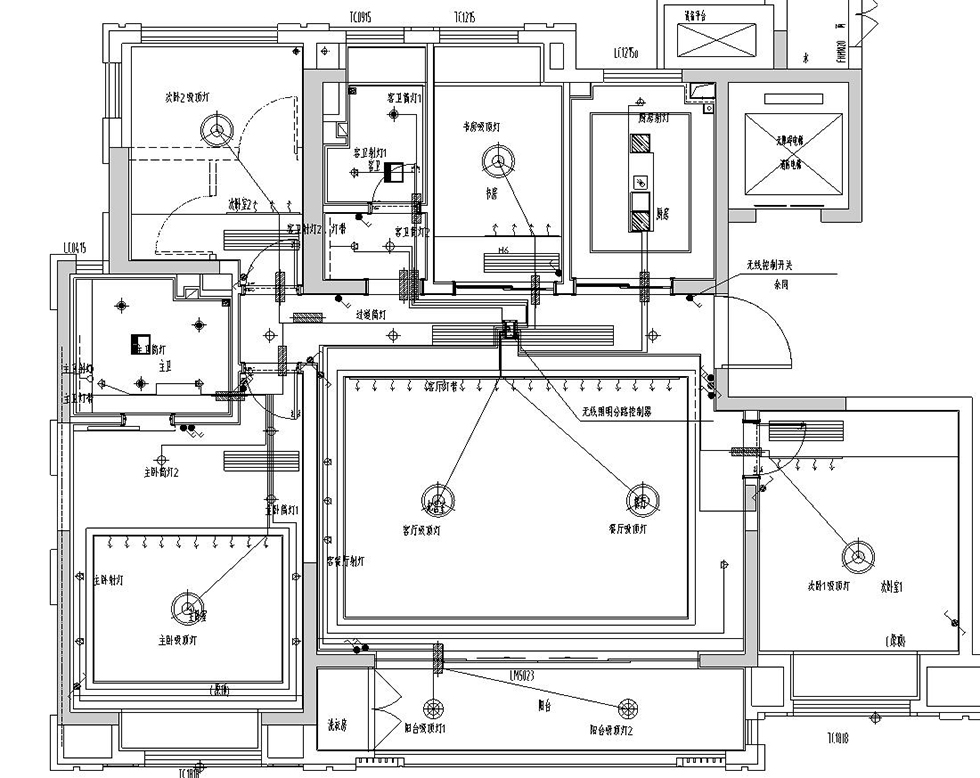

3 application example of residential project the author participated in the indoor electrical design of a fine decoration residence.

The indoor distributor products are as follows: in the fine decoration design residence, a distributor is installed in the ceiling of each residence (with lightning protection circuit, which can effectively prevent potential safety hazards caused by lightning stroke, short circuit, overload and leakage of household appliances), which is connected to a strong current incoming line of the indoor distribution box, Connect all lighting control lines in the house (the control circuit of each lamp is counted as one, and the maximum rated current of each wiring terminal is 10a), Wireless panel switches are installed in each room (movable or wall mounted; wireless switches are used instead of traditional wired switches.

Compared with the traditional wall chiseling installation method, it not only saves the installation time, but also protects the strength and integrity of the wall structure).

868.35mhz frequency connection is adopted between the wall wireless switch and the distributor in the ceiling (with the advantages of strong wall penetration ability, strong anti-interference ability and low power).

The distributor can realize the factory control logic with the wireless switch.

At the same time, the wireless switch can also be dialed and adjusted by the user later, Finally, the control relationship between lamps and wireless control switches in the room is realized.

The distributor and its incoming and outgoing lines are set in the ceiling, which does not affect the beauty of the user’s ceiling.

At the same time, there is no need to embed horizontal lighting pipelines in the concrete roof, which can reduce the thickness of the laminated plate by 1 cm.

There is no need to embed pipelines in the vertical PC components between the wireless switch and the lamps, so as to minimize the number of embedded electrical pipelines in the cast concrete structure, Ensure the safety of the cast structure system.

Embedded pipelines and junction boxes are only required in the laminated plate area that cannot be covered by the ceiling.

The wireless switch is powered by solar energy and lithium battery without replacing the battery, and the service life is more than 5 years.

The traditional wired switch is replaced by wireless switch.

Compared with the traditional wall chiseling installation method, it not only saves the installation time, but also protects the strength and integrity of the wall structure.

The wireless switch adopts RF wireless module.

The switch does not need wiring, so there is no need to slot the wall.

It is easy to install.

It can realize the single, double and multiple control of any lamp in the room, so that the control can be easily reached..