Zhou Yizhi, technical R & D member of national civil structure prefabrication and assembly engineering technology research center of Tongji University, master of mechanics and materials, structural engineering, University of California, Berkeley zephyrz@tongji.edu.cn Introduction: precast buildings are the main theme of the next stage in China’s construction field.

In 2016, the guiding opinions of the general office of the State Council on vigorously developing precast buildings (hereinafter referred to as the opinions) proposed to take Beijing, Tianjin and Hebei, the Yangtze River Delta The three major urban agglomerations in the Pearl River Delta are the key promotion areas, other cities with a permanent population of more than 3 million are the active promotion areas, and other cities are the encouraged promotion areas.

They develop precast buildings such as precast concrete structure, steel structure and modern wood structure according to local conditions.

Strive to use about 10 years to make the proportion of precast buildings in the new construction area reach 30%.

The development of precast buildings is a major change in the construction mode and an important measure to promote the supply side structural reform of the construction industry, which is conducive to saving resources, reducing construction pollution, improving labor production efficiency and quality safety level; It is conducive to promoting the deep integration of construction industry and information industrialization, cultivating new industries and new driving forces, and promoting the resolution of excess capacity.

With the gradual transformation of China’s economy from labor-intensive industry to capital and technology intensive industry, the technical development of China’s construction industry for more efficient construction methods, and the increasing expectation and confidence of the market for precast buildings, the development of precast buildings is full of vitality.

However, there are still many problems to be solved.

Especially in the seismic performance, the performance of the older generation of precast buildings is not satisfactory.

In the events of Mexico City earthquake in 1985, Beiling earthquake in 1994 and Izmit Earthquake in 1999, the poor seismic performance of the first generation precast buildings caused serious damage to these buildings.

Whether it is the structural damage of precast steel-concrete beam column joints or the overall damage of precast concrete floors, it shows that new technologies are needed to make up for the lack of seismic capacity of precast buildings.

In recent years, China has continuously deepened the policy reform and implemented in the field of disaster prevention and reduction.

On the issue of combating earthquake disasters, China has put forward important documents such as the regulations on the administration of earthquake resistance of construction projects and some opinions of the Ministry of housing and urban rural development on the popularization and application of vibration reduction and isolation technology in housing construction projects (Provisional).

Vibration reduction and isolation technology is more and more widely used in the field of construction.

In terms of isolation field, nearly 12000 isolation buildings have been completed in China, and the number is increasing.

Isolation technology can greatly reduce the effect of ground motion.

After proper design and construction, it can play a protective effect on its superstructure that is difficult for shock absorption products.

Considering the key indexes such as floor acceleration and inter story displacement angle, it can basically ensure that the superstructure is always in the stage of elastic deformation in the fortification earthquake.

In view of the excellent performance of isolation technology against ground motion and the demand for seismic capacity of precast buildings, it is a general trend to apply isolation technology to precast buildings.

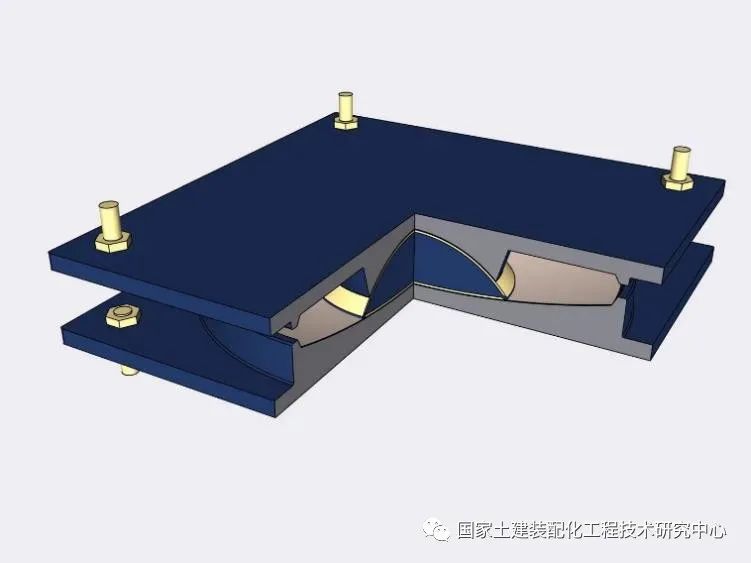

Isolation technology and its application scenario the application of isolation technology in a building is like installing rollers and springs at the bottom of a building.

When an earthquake occurs, the building will have plane displacement, and the force and energy of the main structure will be greatly reduced.

After displacement, the spring like device can restore the structure to its original position.

Compared with the traditional anti-seismic buildings, the advantage of isolation technology is “overcoming hardness with softness” (Fig.

1).

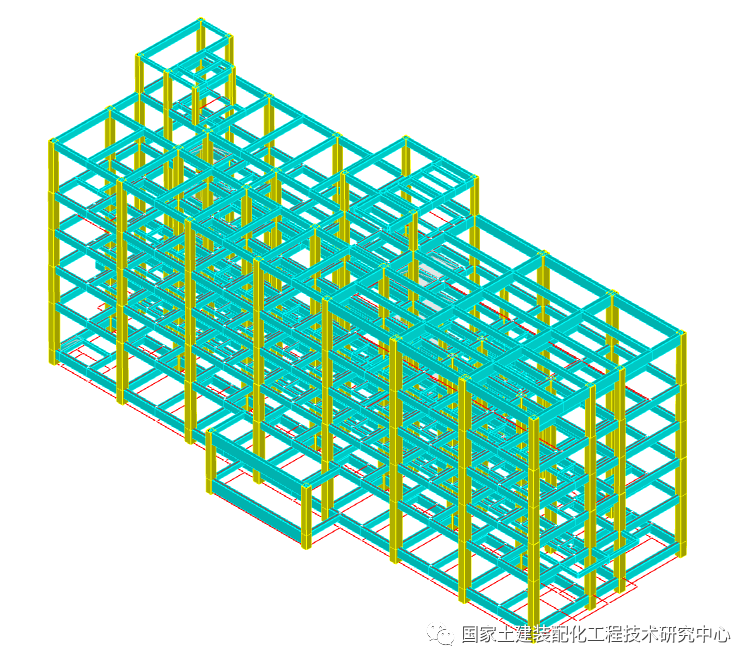

Figure 1 the two cornerstone elements of the isolation structure of the isolation building at the University of California, Berkeley are isolation bearing and damper.

The bearing is generally arranged directly below the structural column, and the damper is arranged freely.

The two together form an isolation layer to support the vertical load, provide the horizontal restoring force, and control the deformation under ground motion.

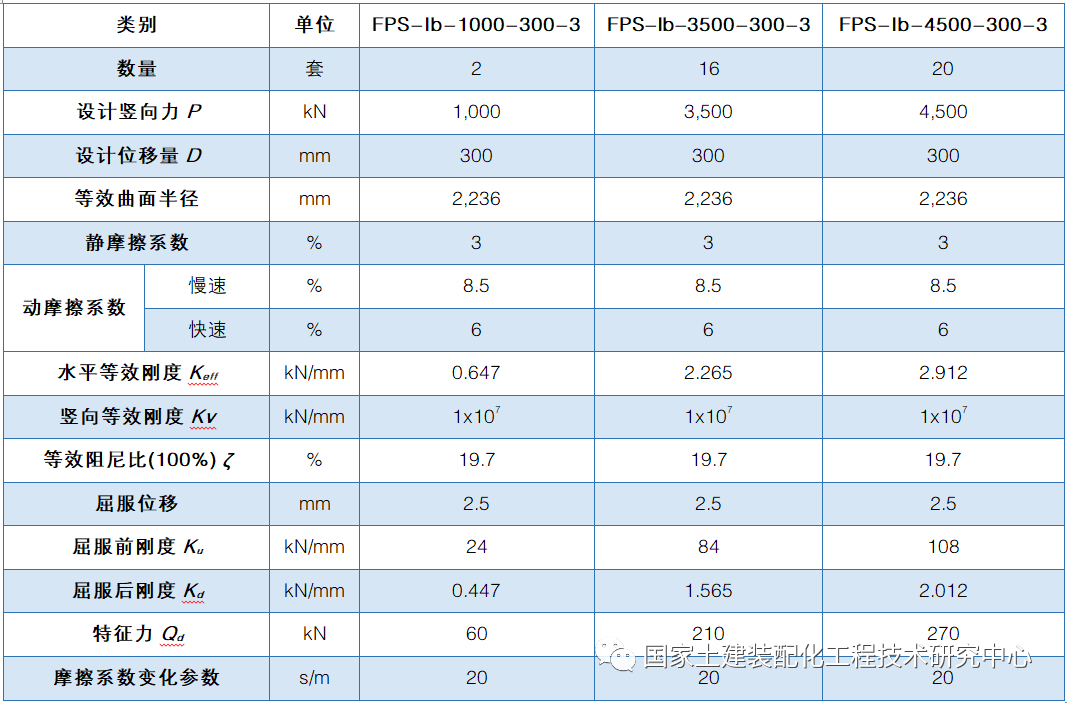

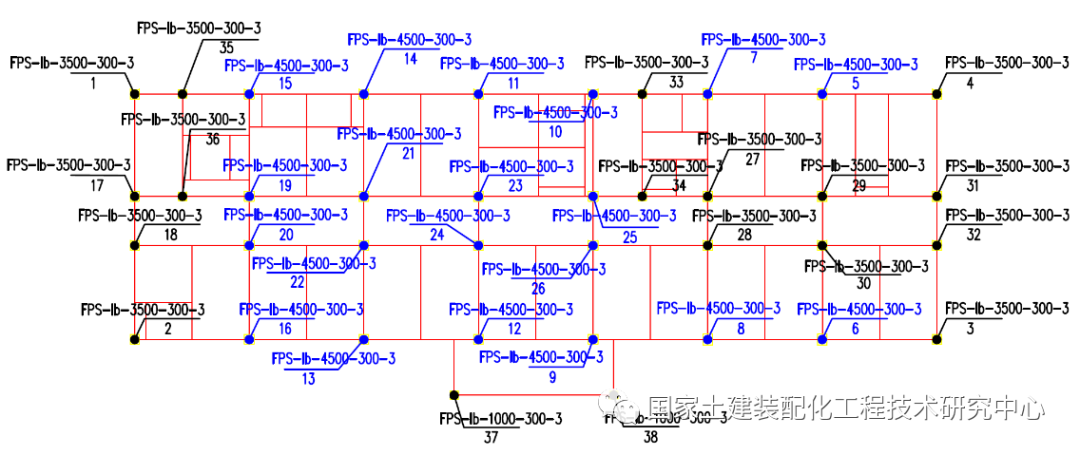

At present, common isolation bearings in the domestic market include laminated rubber isolation bearings (NRb or laminated natural rubber bearing, LNR), lead rubber isolation bearings (LRB), friction pendulum system (FPS or friction pendulum bearing, FPB), etc.

Common isolation layers in China include LRB + LNR combination or FPS only (FPS itself has vertical deformation and is not suitable for mixing with other bearings).

In the isolation building system in Japan, damper adjustment of isolation layer deformation effect is more emphasized.

The layout of common isolation bearings + oil damper / lead damper / metal damper is shown in Figure 2.

Figure 2 the common composite isolation layer of mild steel damper + laminated rubber isolation bearing in Japan.

It should be noted that the isolation bearing is not the panacea to solve the seismic problem of the structure.

Due to the poor tensile stress capacity of the isolation bearing itself, especially if the friction pendulum bearing has no energy dissipation in the tensile state, the base isolation is not suitable for super high-rise buildings.

For the base isolation of high-rise buildings, it is necessary to make a detailed analysis of the tensile stress that the structure may produce in the earthquake.

In addition, because the vibration of isolated buildings the first mock exam, the superstructure design should not be flexible.

The site should not be exposed to high liquefaction risk, that is, the isolation structure is on the low floor, the site conditions are I, II and III (IV class site design should take additional measures), and the upper structure has large rigidity, which can maximize the role of the seismic energy of the isolated buildings..