Source: copyright of Zhulong forum belongs to the project overview of the original author.

The total construction area of the project is about 140000 M ²。 It includes a sales center, 6 residential buildings and underground garage.

The building form is reinforced concrete shear wall structure.

Among them, the board, staircase, air conditioning board and partition wall of the residential building.

It is completed in the form of cast structure.

Other structures are completed by cast-in-situ.

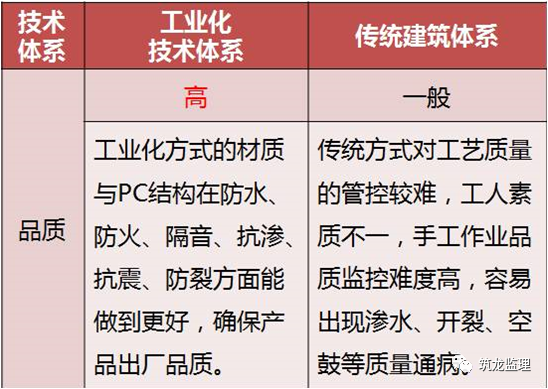

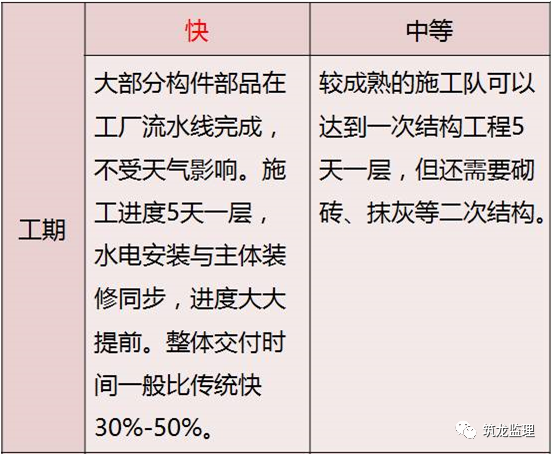

Features and advantages of precast buildings a large number of building components are produced and processed in the workshop.

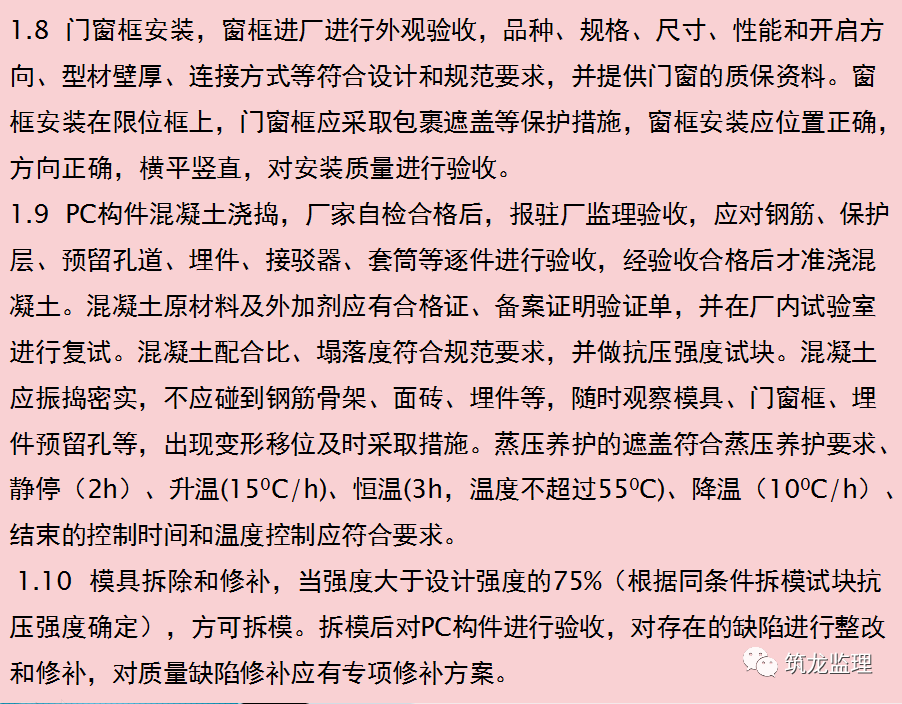

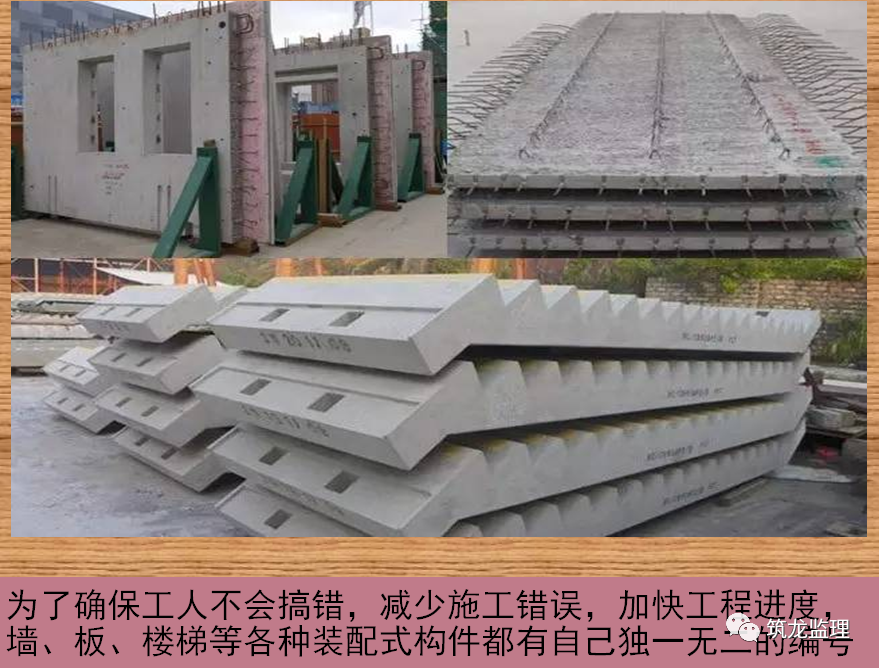

The main types of components include: exterior wall panels, interior wall panels, laminated plates, balconies, air conditioning panels, stairs, precast beams, precast columns, etc.

A large number of assembly operations on site are greatly reduced compared with the original cast-in-situ operation.

The integrated design and construction of architecture and decoration are adopted.

The ideal state is that the decoration can be carried out simultaneously with the main construction.

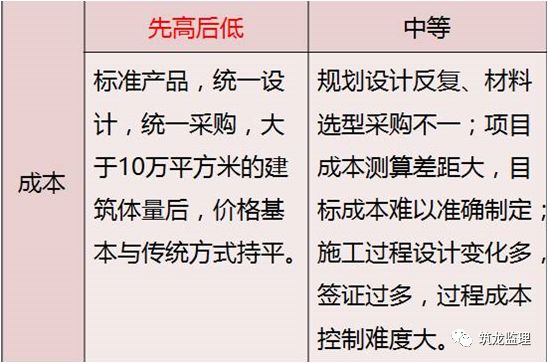

With the standardization of design and informatization of management, the more standard the components are, the higher the production efficiency will be, and the corresponding component cost will decrease.

With the digital management of the factory, the cost performance of the whole precast building will be higher and higher.

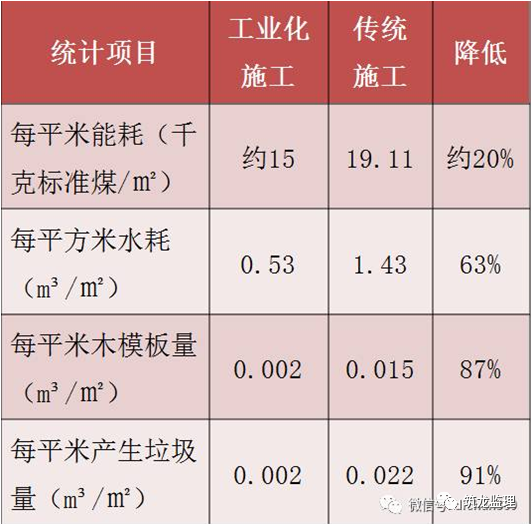

Meet the requirements of green building.

Disadvantages due to the low popularity and high cost, some cast structures can not shorten the construction period, require accurate setting out, accurate elevation measurement and small allowable error, and have high requirements for the position accuracy of reserved holes.

The gap at the bottom of the plate is in an eight shape, which may fall off easily after pointing, and the size of precast components also has a certain error.

Sometimes the gap is too large or uneven integrity during assembly, The seismic resistance is relatively weak.

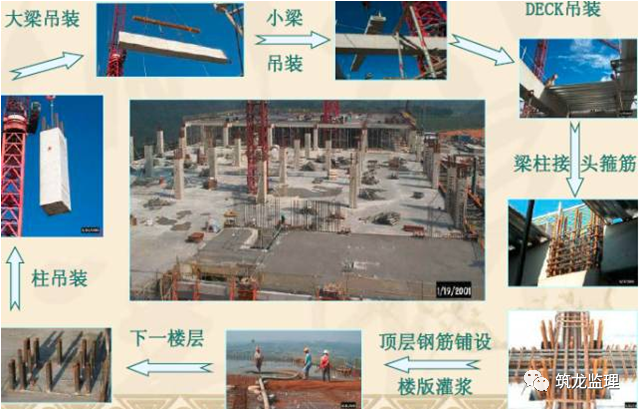

The characteristics of the cast structure in the ideal state are the construction process of the cast building.

The lower space of the cast column hoisting is narrow and inconvenient to observe.

Through the reflection principle of the small dressing mirror, it is convenient to plug the reserved reinforcement in the lower layer and the holes in the upper cast column, so as to increase the connection between the cast components and the cast-in-place layer and ensure the reliability and safety of the structure, The surface of cast components shall be provided with keyways or roughened.

There are various connection modes between cast components.

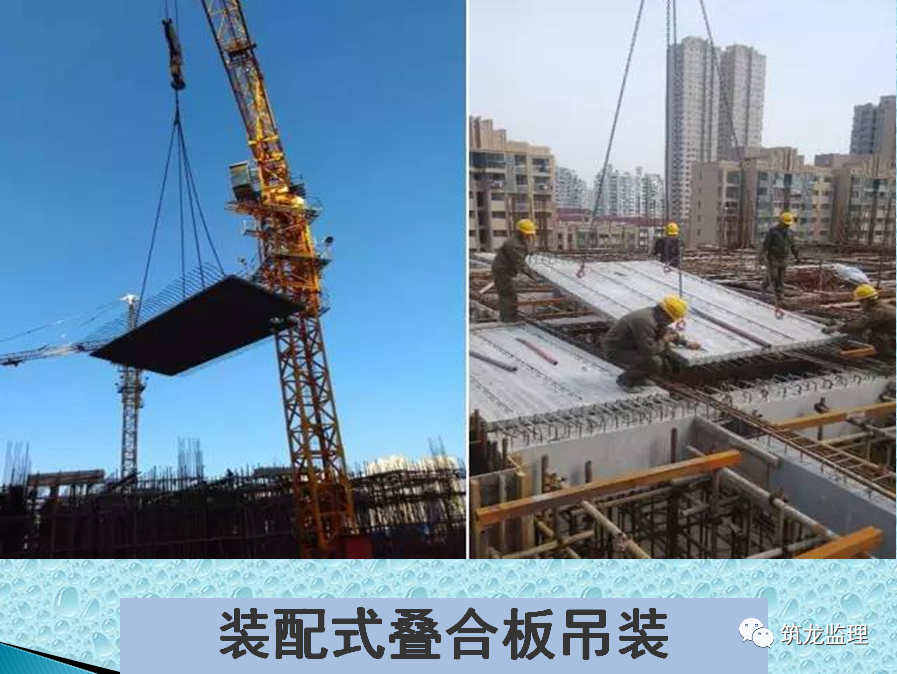

At present, the floor slab is usually in the form of 7 + 8 (70mm thick precast floor slab + 80mm thick cast-in-situ layer).

After hoisting, bind the reinforcement of the cast-in-situ layer and prepare to pour the concrete of the cast-in-situ layer.

Key points of supervision and control for the construction of assembled integral concrete structure 1.

Key points of PC component fabrication 2 Key points of PC component installation supervision work supervision work methods and measures 1.

PC component processing supervision work methods 2.

PC component installation control supervision work methods: 3.

Quality acceptance requirements of PC structure 4.

Supervision measures of PC processing and installation control 5.

PC construction supervision safety management of sub divisional works acceptance of PC assembled integral concrete structure 1.

General provisions of safety management 2 Safety protection points of PC component installation and construction 3.

Safety points of PC installation and construction 4.

Safety supervision measures and methods dust control points of supervision internal management Spring Festival benefits.