Source: after enterprise application, local recommendation and expert review, the Ministry of housing and urban rural development recently determined and released the first batch of 124 typical cases of innovative services of new technologies and new products for intelligent construction.

The purpose is to summarize and promote the replicable experience and practices of intelligent construction, and guide local competent housing and urban and rural construction departments and enterprises to comprehensively understand and scientifically select intelligent construction technologies and products.

Among the typical cases released this time, there are 20 innovation service cases of independent innovation digital design software, 29 innovation service cases of intelligent production line of parts and components, 42 innovation service cases of intelligent construction management system, 20 innovation service cases of Internet platform of construction industry, and 13 innovation service cases of intelligent construction equipment such as construction robot.

Now, 124 typical cases of intelligent construction new technology and new product innovation services are introduced in detail in batches.

This issue is part and component intelligent production line series (IV): Zhengzhou Baoye steel member production line, Shandong lvxia steel member production line, Zhejiang construction engineering H-beam production line, Guangdong Huizhou CSCEC steel member production line, Shanxi Xiaohe heavy H-beam Box girder and column production line Zhengzhou Baoye steel structure production line 01 case introduction Zhengzhou Baoye steel structure production line is composed of intelligent blanking center, component processing center, intelligent distribution center, intelligent H-section steel forming center, intelligent section steel processing center and intelligent assembly and welding center, which can realize automatic blanking, intelligent inspection, intelligent distribution of parts, assembly, welding and straightening of H-section steel, one-time forming The integration of intelligent processing and intelligent assembly and welding of H-beam.

The information management platform supporting the production line covers the functions of enterprise resource technology, product life cycle, supply chain management, warehouse management, manufacturing execution, energy management, data acquisition and monitoring and equipment physical layer management.

It can realize production simulation analysis, progress tracking, automatic production scheduling, process energy consumption analysis, real-time tracing of assembly components, optimal cost control Comprehensive visual operation and maintenance management such as real-time decision-making.

Compared with the traditional production line, the number of single line workers in the production line is reduced from 80 to 16, the employment is reduced by 80%, the unit area is increased from 1.2t/m2 to 1.5t/m2, the production efficiency is increased by 25% and the comprehensive cost is reduced by 20%.

02 case application scenarios and technical product features (I) key points of technical scheme the project aims at improving production capacity, reducing personnel and increasing efficiency, energy conservation and environmental protection and improving quality.

Based on intelligent production line and one-stop intelligent manufacturing information management platform, it creates a full life-cycle management mode covering steel structure design, procurement, manufacturing, installation, testing and other links, Realize the visualization, refinement and informatization management mode of the whole production and construction process of the steel structure industry, integrate the upstream and downstream resources of the industrial chain, and enhance the industry cooperation ability.

1.

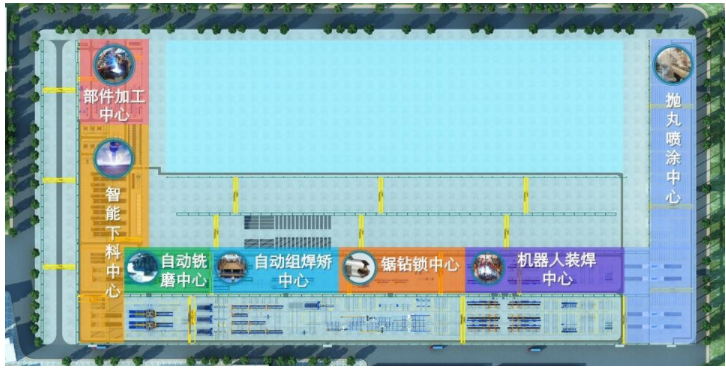

Intelligent production line Baoye steel structure intelligent production line (six intelligent manufacturing centers) is composed of intelligent blanking center, component processing center, intelligent distribution center, intelligent H-section steel forming center, intelligent section steel processing center and intelligent assembly and welding center (as shown in Figure 2).

It corresponds to each process of steel structure production and manufacturing to realize automatic blanking and intelligent inspection of parts, The integration of parts intelligent distribution, one-time forming of H-beam assembly, welding and straightening, intelligent processing of H-beam and intelligent assembly and welding can meet the intelligent manufacturing of 40% components of steel structure buildings.

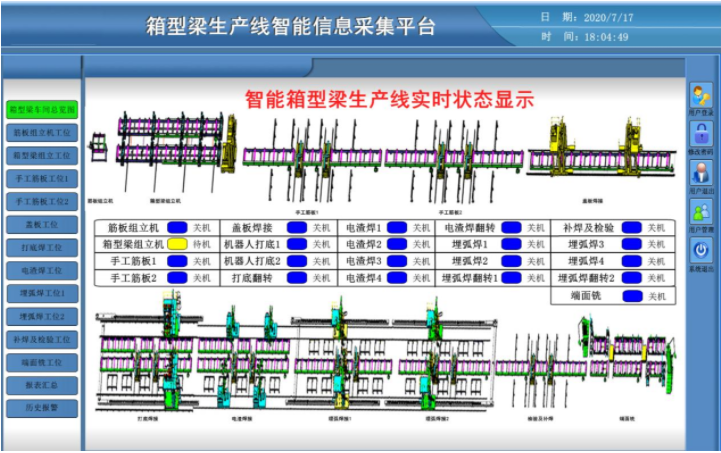

Figure 2 steel structure intelligent manufacturing six centers 2 One stop intelligent manufacturing information management platform one stop intelligent manufacturing information management platform takes “one platform, two levels, eight aspects and four types of data” as the construction idea of the platform (as shown in Figure 3), integrates OA, NC, e-commerce and financial systems, covering enterprise resource technology, product life cycle, supply chain management, warehouse management, manufacturing execution, energy management The functions of data acquisition and monitoring and equipment physical layer management integrate the four dispatching centers of visual management (as shown in Figure 4), realize the visualization and quality analysis of the whole life cycle from design, production and manufacturing to on-site installation, ensure the transparency of production data from the bottom to the top, and realize production simulation analysis, progress tracking, automatic production scheduling, process energy consumption analysis All round visual operation and maintenance management such as real-time traceability of assembly components, optimal cost control and real-time decision-making.

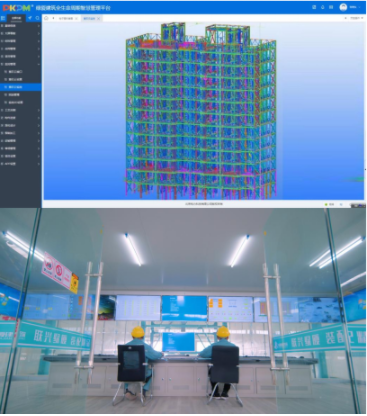

Figure 3 platform construction idea} Figure 4 four dispatching centers 3 Baoye steel structure intelligent control center Baoye steel structure intelligent control center (as shown in Figure 5) takes “data center, interaction center, general control center and decision center” as the construction concept, so that the company’s management can realize remote dispatching of “one-stop intelligent manufacturing information management platform” and know the real-time production status, equipment operation, project progress and production progress of the plant at any time, At the same time, 5g technology is integrated, 5g + UAV, 5g + smart helmet, 5g + ultra-high definition camera and other means are used to solve the problems of personnel, safety and quality management on the construction site, and finally realize the visual management of construction services covering the whole life cycle of supply chain production workshop and products, so as to improve the scientific decision-making ability of enterprises.

Figure 5 key technologies of Baoye steel structure intelligent control center (II) open up the data link of the whole process of steel structure design, manufacturing and installation through big data, Internet of things, BIM Technology and 5g technology, realize the interconnection of customers, suppliers and managers, realize the intellectualization of steel structure production, digitization of manufacturing, intelligent connection of equipment and visualization of management, and form a design standardization model Production process model, process model, quality control model, pre assembly model and intelligent service model, and finally complete the whole life cycle management of design, procurement, part processing, logistics transportation, installation and maintenance in the construction process.

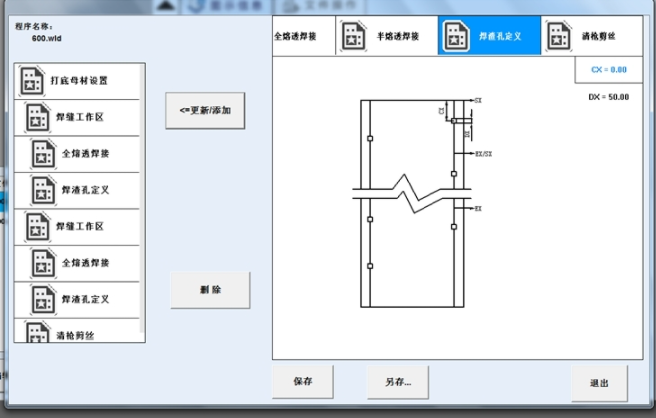

(III) innovation points 1 Based on the technological innovation of one-stop intelligent and information management platform of production process (1), an efficient data acquisition and interconnection system is established (as shown in Figure 6)..