During the maintenance and reinforcement of the wooden frame, the following seven situations will usually be encountered (frame deflection, member fracture, beam tenon pulling, column heel decay, wing angle sagging, cornice folding, Dougong outward inclination).

When the frame deflection, member fracture and local collapse of the building occur, the rescue and reinforcement measures shall be taken immediately after the investigation and identification of the dangerous situation.

The maintenance construction shall be carried out after the detailed maintenance scheme is determined.

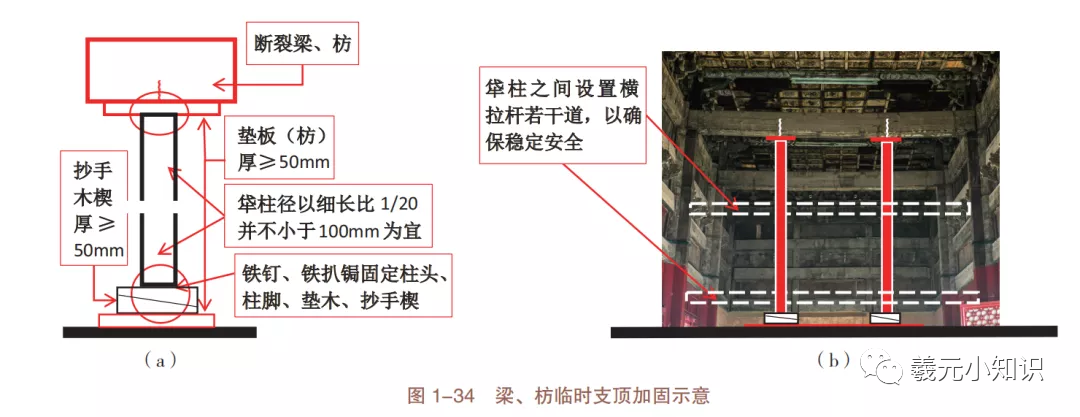

Component fracture when the building beam, brace, purlin and other components have transverse fracture, measures such as roof support and reinforcement must be taken at the fracture immediately to avoid greater damage to the main body of the building.

1: The procedure is to determine the roof support reinforcement scheme → site leveling and cleaning → preparation of reinforcement tools and materials → component protection → roof support installation.

2: Method (1) determine the roof support reinforcement scheme and comprehensively determine the reinforcement party according to the actual situation on site ① determine the roof support method according to the fracture position and degree of the component.

② Whether the strength of the ground at the supporting part of the site is sufficient to meet the load-bearing requirements.

If not, the method of paving wood plates to disperse and concentrate the load can be adopted.

③ Remove the obstacles affecting the roof support construction.

If there are immovable animals with cultural relics value, they shall be preserved and protected.

④ set several transverse tie rods according to the height of the supporting column to avoid instability.

(2) The site shall be leveled and the supporting part shall be cleaned to confirm that the strength of the ground at the supporting part can meet the bearing requirements.

(3) reinforcement tools and materials preparation ① tools: axe, sledgehammer, nail hammer, saw, wrench, crowbar, Jack, etc.

② materials and facilities: supporting column, pull rod (wood brace or steel pipe), base plate (brace), hand reading wedge, steel wire rope, supporting bolts, lead wire, iron nails, iron raking curium and mobile shelf used for operation.

(4) for component protection, the supporting part shall be padded with cotton blanket materials and wood (brace) to avoid damaging the original components and the paint paintings on the components.

(5) roof support installation 牮 ① the roof support column can be made of Chinese fir pole or pine; The pull rod shall be pine brace or steel pipe; Red and white pine should be used as the cushion wood (brace), and larch should be used as the hand reading wedge; The diameter of the column should not be too thin or too thick, and the slenderness ratio is about 1 / 20.

See the following figure for details.

Schematic diagram of temporary top support reinforcement of beams and braces reference case of temporary top support reinforcement reference case of temporary top support reinforcement reference case of temporary top support reinforcement ② the ground of the top support is paved with skids, and the skids on the bottom of beams (braces) are fastened with iron nails.

③ put the column in place, firmly back the hand reading wooden wedge, and fasten the column head, column base and hand reading wooden wedge with iron raking curium, iron nail and wood pad to prevent the introduction of knowledge – repair of cultural relics buildings, wood carving, and 12 wooden works of traditional Chinese buildings from sliding.

④ Tie rods are set between the columns and building components for fixation.

⑤ Since it is only the temporary reinforcement of the building for emergency rescue, as long as the condition of the broken parts of the beam and brace does not continue to increase, it is not necessary to jack up and return the columns supporting the roof.

(the content comes from the Internet)..