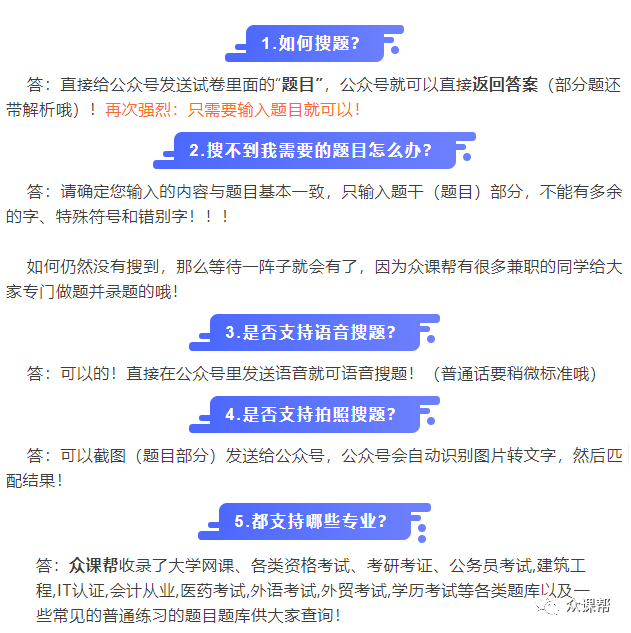

Failure analysis of metal components (Shandong alliance) – Wisdom Tree – knowledge – online course answers help you get full marks in all kinds of exams! Duplicate your question “long” by identifying the two-dimensional code, and send it to the “public class assistance” official account.

Simple and convenient, the answers are basically seconds back! In case of a large number of queries, the maximum delay is 1-2 seconds.

Please understand.

The tutorial for finding answers is as follows: 1.

If a technical index of a failed component does not meet the technical requirements, it can be determined as the cause of component failure.

Answer: wrong ——————————– 2.

The differences between failure analysis and waste analysis are: A.

different analysis objects B.

different analysis methods C.

different analysis purposes D.

different basis for judging right and wrong answer: different analysis objects; The purpose of analysis is different; The basis for judging right and wrong is different ——————————— 3.

The significance of failure analysis is: A.

it helps to improve the management level and product quality of the enterprise B.

it helps to distinguish responsibilities and protect the interests of users C.

It is the basis for revising product technical specifications and standards D Promote the development of materials science and engineering answer: help to improve the management level and product quality of enterprises, help to distinguish responsibilities and protect the interests of users, is the basis for revising product technical specifications and standards, and promote the development of materials science and engineering ——————————– 4.

Precautions for failure analysis are: A.

conduct in-depth investigation and research B Carefully formulate failure analysis procedures to avoid blindness and one sidedness C.

pay full attention to the complexity and comprehensiveness of failure analysis and avoid technical limitations D.

respect objective facts, adhere to seeking truth from facts and eliminate human interference answer: conduct in-depth investigation and research, seriously formulate failure analysis procedures to avoid blindness and one sidedness, and pay full attention to the complexity and comprehensiveness of failure analysis, Avoid technical limitations, respect objective facts, adhere to seeking truth from facts, and eliminate human interference ——————————– 5.

Due to the backwardness of technical means, modern failure analysis failed to reveal the essence of component failure from the micro level.

Answer: 1.

The characteristics of failure process are: A.

irreversibility B.

disorder C.

instability D.

cumulative answer: ABC ——————————————– 2.

Which of the following are the ideas and methods of correlation analysis: A.

analysis according to the whole manufacturing process and service conditions of failed components B, “four M” analysis method C, fault tree analysis method D Analyze according to the failure form of failed components answer: fault tree analysis method; Characteristic factor diagram analysis method ——————————– 3.

The principles to be followed in collecting the background materials of failed components are: A.

practicability B.

timeliness C.

subjectivity D.

objectivity answer: practicability timeliness objectivity ————————– 4.

The specific failure process of components can be reproduced through simulation reproduction test, It can completely replace the actual failure process of components.

Answer: wrong ——————————– 5.

Reasoning in failure analysis is a logical means.

Reasoning can only provide reference, clue and direction for failure analysis, not as evidence.

Answer: Yes ——————————– 1.

Bright white structure appears on the casting section and it is difficult to carry out machining.

This defect is called white mouth defect.

Its main constituent phases are: A, ferrite B, austenite C, graphite D and cementite answer: cementite ——————————– 2.

In the traditional strength theory, Which plastic yield criteria are applicable to plastic materials: A, first strength theory B, second strength theory C, third strength theory D, fourth strength theory answer: third strength theory; Fourth strength theory ——————————— 3.

The existence of Widmanstatten structure in forgings will reduce the strength and toughness of forgings.

Answer: Yes ——————————– 4.

The steel has overburning during heat treatment.

Its metallographic characteristics are: A.

coarse grain B.

increased strength C.

oxidation or melting of grain boundary D.

increase of carbide at grain boundary answer: oxidation or melting of grain boundary ————————– 5.

Most of the casting cold cracks expand along the grain boundary microscopically..