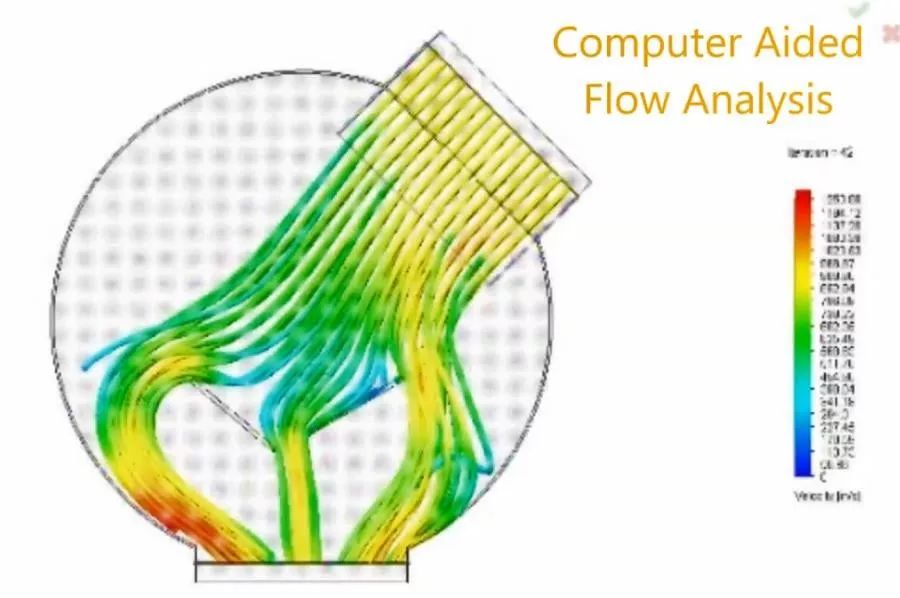

The silo feeding has great impact on the conveying pipeline and rapid wear.

Material leakage and ash leakage after wear involves high-altitude operation and difficult maintenance, which is the pain point of production and maintenance.

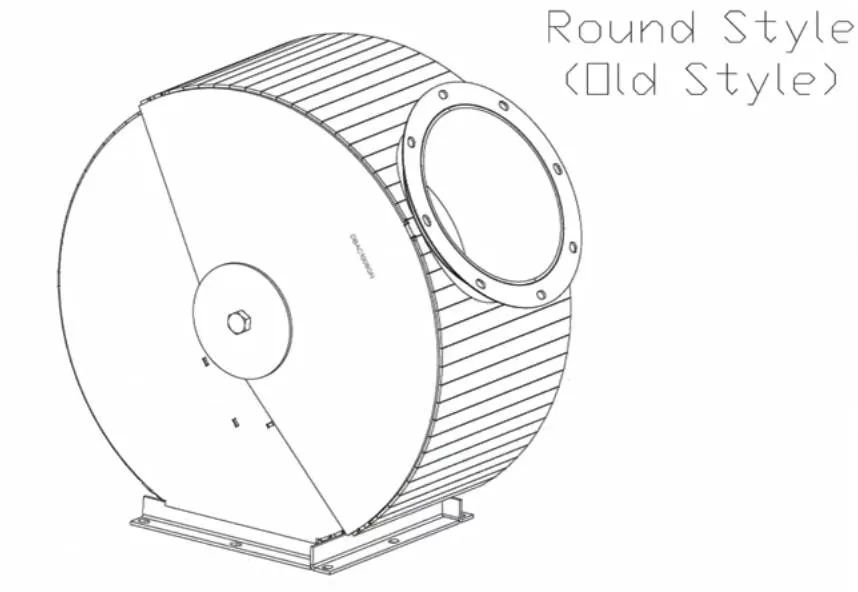

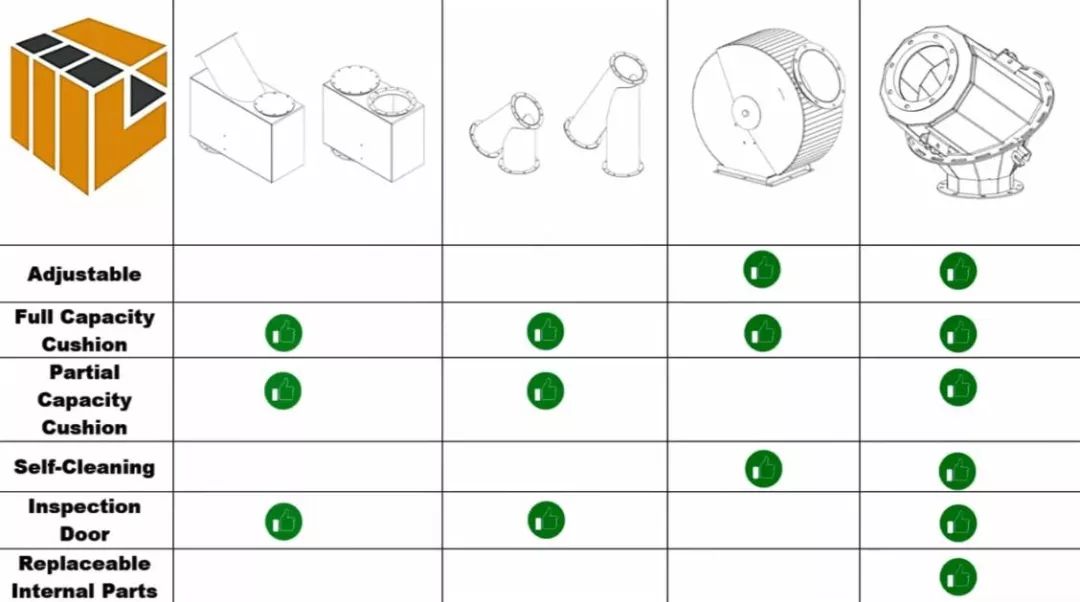

The following describes the methods of several common buffer sections, which are easy to use.

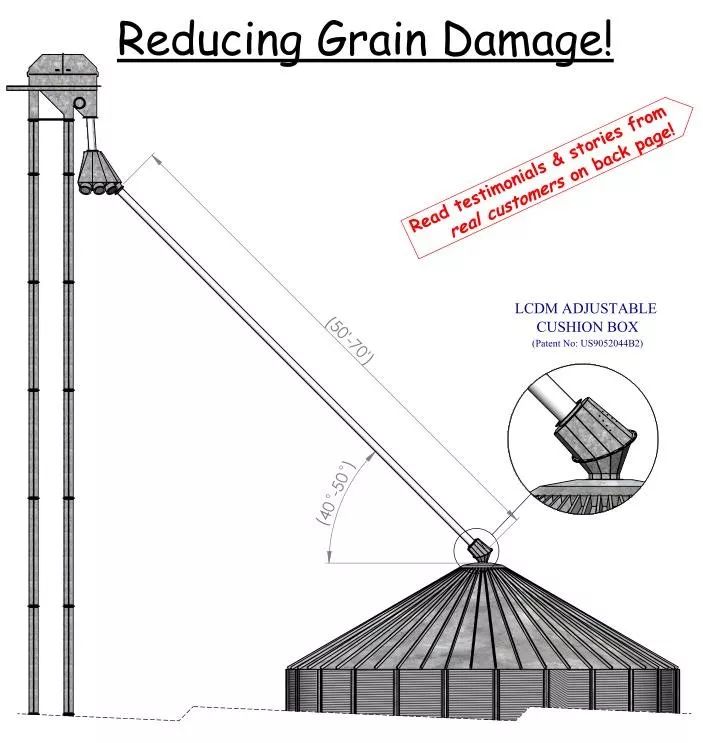

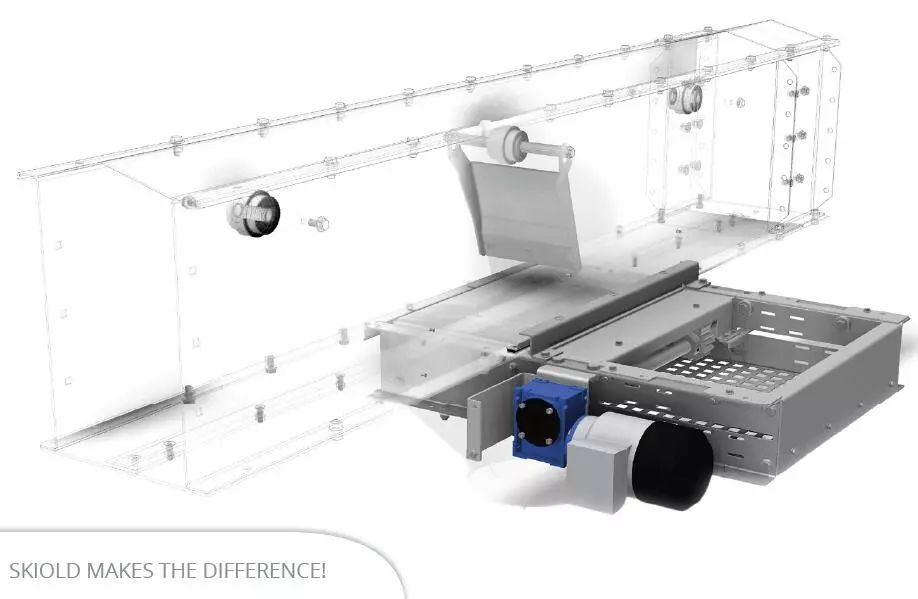

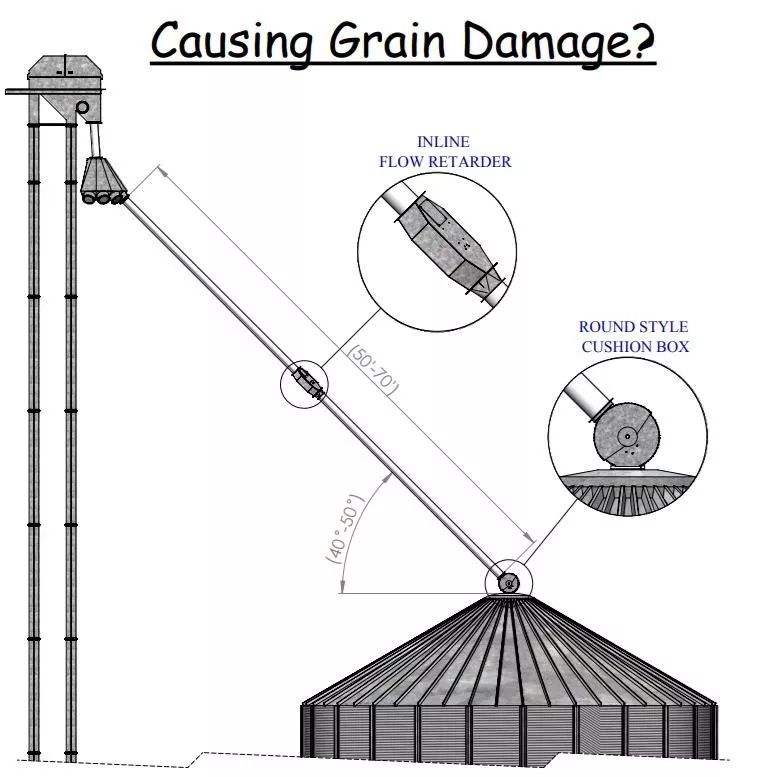

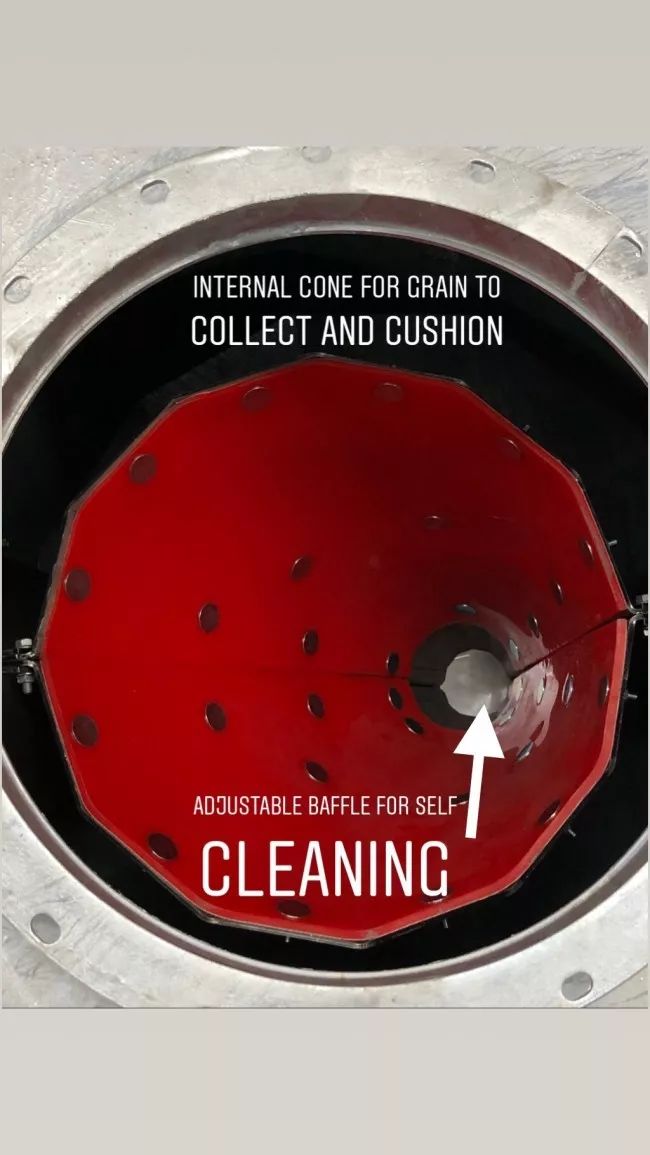

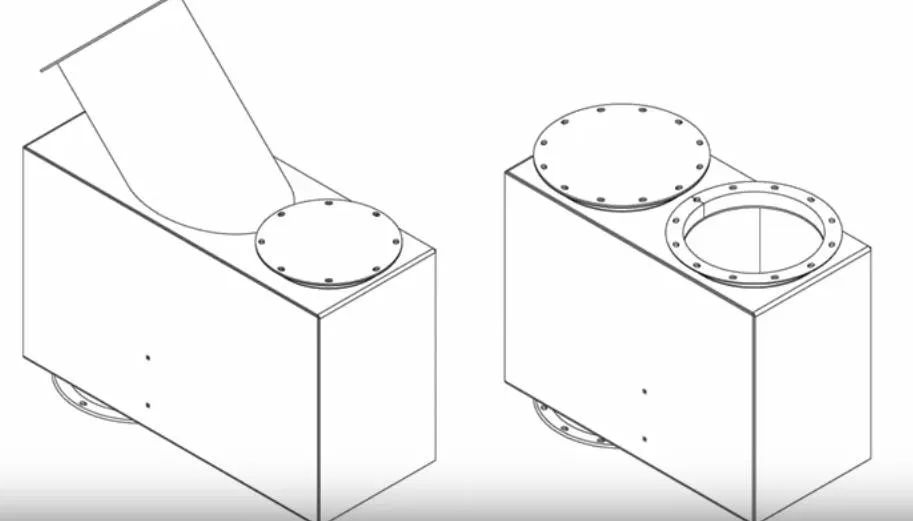

Remember the internal structure of the buffer section of the collection ~ square box 👇 Side plate angle adjustable 👇, To regulate the overflow flow.

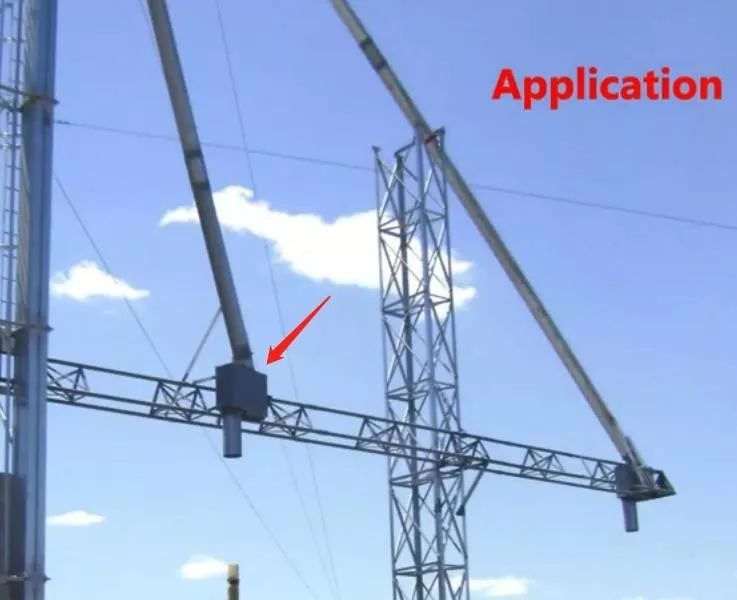

Advantages of round head buffer section: the installation angle is adjustable.

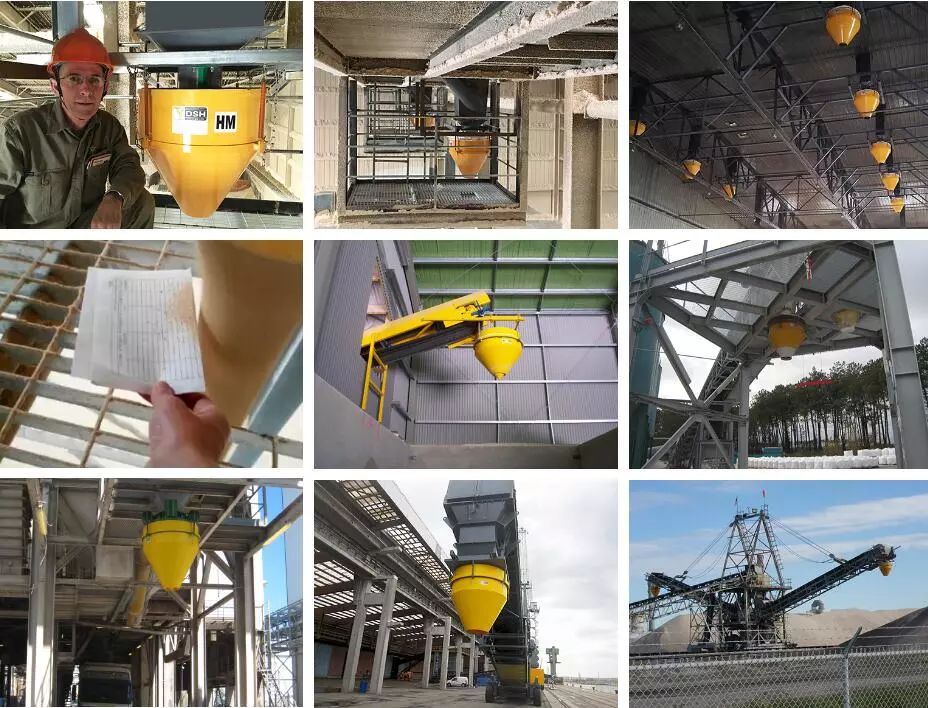

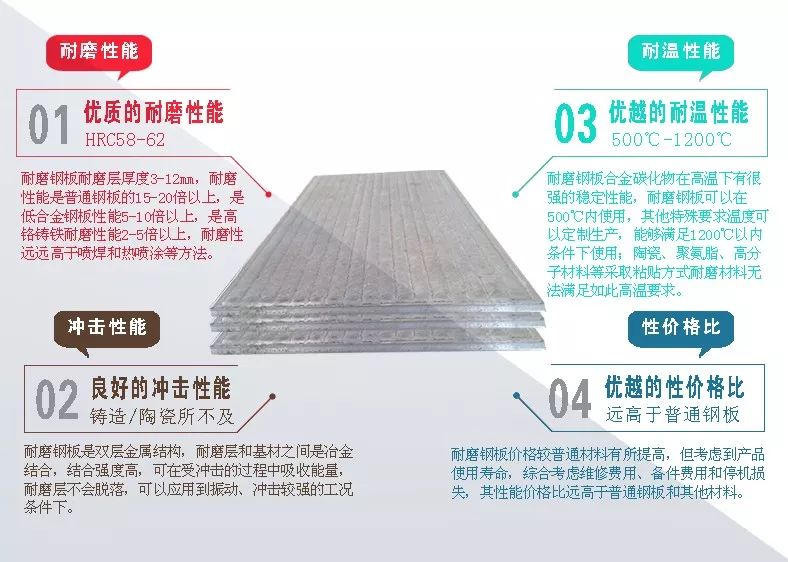

Principle: internal V-baffle 👇 Dbar # adjustable buffer section LCDM patented product 👇 Square chute wear plate ceramic plate patch 👇 Polymer wear resistant plate 👇 Summary and comparative analysis of other common practices https://lcdmcorp.com/PENNSYLVANIA871RangeEndRoadDillsburg ,PA17019INDIANA1611NorthBinkleyRoadLarwill,IN46764Telephone: 888-963-9145Text:717-514- 4321contact@LCDMcorp.com Refer to the angle adjustable design of blind end joint of granular chute | prefabricated parts 👇 So far, the most effective solution for bulk falling dust: application progress of DSH dust suppression system (dust hopper) | dust 👇 Low stress abrasive wear resistant hard faced wear resistant steel plate | wear resistant 👇 Selection of wear-resistant lining plate at the bottom of scraper conveyor | scraper 👇 Let the scraper no longer carry material| transportation 👇>> Modern feed engineering and machinery < < committed to becoming the most professional media tool with industry insight and promoting industry application-oriented innovation.

> > ModernFeedEngineeringAndMachinery<