Click the blue words above to pay attention to us.

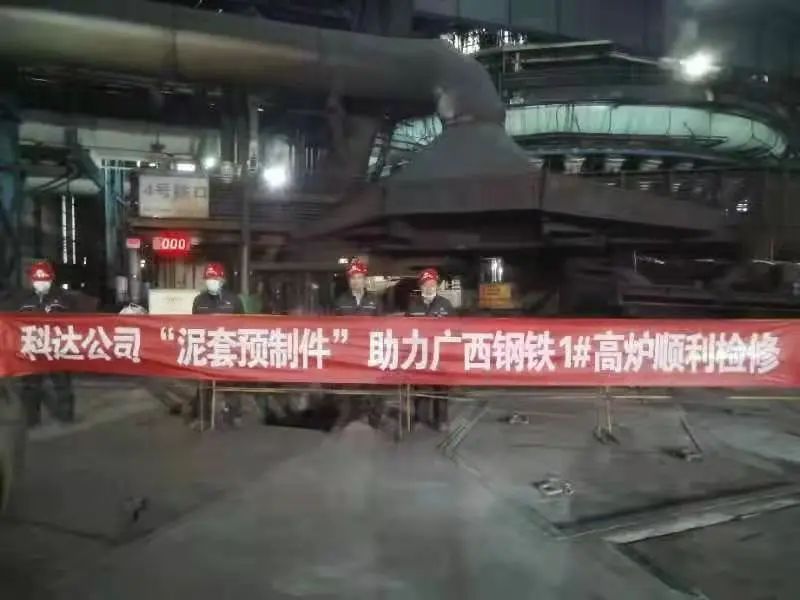

Recently, the “mud jacket prefabricated parts” produced by Anyang Keda metallurgical pouring materials Co., Ltd.

were successfully applied in Guangxi iron and steel 1# blast furnace, helping the blast furnace to complete the maintenance smoothly.

Patent name: an integral molding mud sleeve device with the function of controlling the splashing of blast furnace iron mouth patent number: 202020517396.8 patentee (unit): Anyang Keda metallurgical pouring material Co., Ltd.

It is reported that the hydraulic mud gun for blocking the iron mouth of blast furnace needs to be in close contact with the iron mouth mud sleeve, and the refractory mud is driven into the iron mouth through the high pressure of the hydraulic gun to block the iron mouth, So as to complete the process of iron port plugging.

Due to the high pressure of the hydraulic clay gun, when contacting with the iron mouth clay sleeve, it will cause huge impact force on the iron mouth clay sleeve.

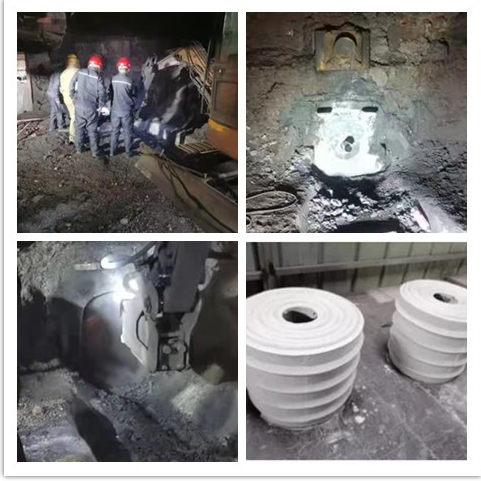

Therefore, in order to maintain the integrity of the iron mouth clay sleeve and the flatness of the contact surface, and successfully complete the plugging operation of the hydraulic clay gun, it is necessary to repair the integrity of the iron mouth clay sleeve and the flatness of the contact surface between the clay sleeve and the hydraulic clay gun regularly.

The traditional iron mouth mud sleeve needs to be repaired and made manually and frequently.

The current situation of the use of the artificial mud sleeve is as follows: 1.

The use time of the artificial mud sleeve is relatively short and the labor intensity of the workers is high.

Making a new iron mouth mud sleeve can take about 20-30 days, or even less.

Workers need to repair and make the mud sleeve regularly, and the labor intensity of workers is high.

2.

The quality of the artificial mud sleeve is unstable and the reliability is poor.

The quality of the manually made iron mouth mud sleeve is unstable, and the integrity and flatness of the mud sleeve are completely made by manpower and experience.

In the process of use, it is very easy to cause the damage and incompleteness of the mud sleeve, so that the contact between the hydraulic mud gun and the iron mouth mud sleeve is not tight, resulting in the failure of the blast furnace to block the iron mouth, resulting in major production accidents.

The maintenance free iron mouth mud sleeve of blast furnace produced by Anyang Keda metallurgical pouring materials Co., Ltd.

is formed by firing special refractory and installed at the part of iron mouth mud sleeve to replace the mud sleeve that needs to be made regularly.

The service life of the mud sleeve preform is at least one year, which not only saves the refractory material for making the mud sleeve, but also greatly reduces the labor intensity of workers and improves the success rate of safe plugging of blast furnace.

The installation position of maintenance free taphole mud sleeve of blast furnace is the place where cracks are most likely to occur at the taphole of blast furnace, resulting in splashing and gas leakage at the taphole.

By installing the maintenance free iron mouth mud sleeve, refilling the castable in this part and controlling the cracks in the internal refractory, it has the function of controlling and alleviating the splashing of the iron mouth in the process of tapping.

Exchange hotline: Zhang Wen’an 13703466832..