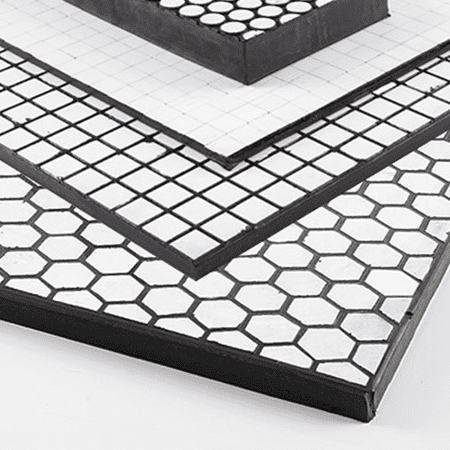

Ceramic wear liners as a leader in the field of ceramic tile lining, LCDM company provides many choices for projects using ceramic tile lining kit, which is one of the most wear-resistant and durable materials at present.

The most common products lined with this material are transition chute, adjustable elbow, square buffer section, valve, hopper and other components.

LCDM can also provide brown and pink tile linings for the rice industry.

In order to save time on site, LCDM tile lining will customize the cutting pieces to any required size.

Application Industry: > > agriculture: feed processing plants and grain processing plants use ceramic lining to protect their stored products (such as corn, wheat, barley, oats, rice, etc.) in the process of entering and leaving the silo.

> > Oil and gas: in oil, gas and refining, ceramic linings protect pipes and chutes from abrasives used in the manufacturing process.

> > Mining: in mining applications, ceramics can resist the abrasion of crushed ore, fine sand and mud.

> > Concrete: during the production of concrete and cement, ceramics can protect equipment from friction caused by materials.

> > Construction and heavy equipment industry: industries that use trucks in operation can lay ceramics on some means of transport to control damage.

Advantages of ceramic lining LCDM company can provide ceramic lining to meet the needs of users.

LCDM’s knowledge of the material handling industry enables it to develop products and systems to improve and improve users’ demand for grain or other material handling efficiency.

Simple and reliable ceramic lining is a cost-effective lining solution.

The manufacturing team of LCDM company focuses on the power of high-quality design and materials without redundant decoration.

LCDM will obtain ceramics with reliable performance at a reasonable price.

> > Enjoy the following benefits: durability and reliability, prevent corrosion and wear, so as to prolong the service life of the system and improve the grain quality.

Through the reliable system, provide the smoothness and speed of materials to maintain a high level of grain quality.

Due to the natural corrosion resistance of ceramics, it can provide impact protection under high flow conditions.

LCDM ceramics can reduce noise and vibration during operation.

> > Reliable epoxy bonding in addition to our ceramic lining bricks, LCDM also sells adhesives and epoxy kits for bonding them to your system.

Siliconeandepoxykit is selected from two options: > two-part epoxy Kit: it has a formula that can firmly bond ceramics to the valley logistics system.

It is suitable for most ceramic, metal, concrete, fiberglass and wood surfaces.

> Two part epoxy kit with ceramic beads: if you need to repair part of the system before lining the system, please use LCDM’s two-part epoxy kit with ceramic beads.

This special formula includes ceramic beads that maintain the life of the product.

> > Longer service life LCDM ceramics extend the service life of the system, thus saving long-term costs.

The combination of natural and durable ceramics and firmly bonded epoxy resin can provide reliable system protection.

With LCDM ceramics, you can also replace some at a time without a complete replacement.

Strategically replacing LCDM ceramics can help you prolong the service life of your equipment for a longer time.

Comparison of ceramic and polyurethane lining in grain flow system, you can use a variety of lining materials, including ceramic and polyurethane.

In LCDM, we also specialize in the production of polyurethane lining.

We welcome your decision to seek advice from our friendly and knowledgeable experts.

Polyurethane has greater flexibility than ceramics and is a valuable investment in lining.

On the other hand, ceramics have the following advantages: > > wear resistance LCDM ceramics are one of the most abrasion resistant lining options available.

The price of ceramics will be higher, but the service life is longer than that of polyurethane liner (it can save you money in the future).

On average, the service life of ceramics is about 40 times that of polyurethane.

> > Simple installation and maintenance the installation process of ceramic lining on site consists of two parts: ceramic and epoxy resin.

Please follow LCDM’s epoxy kit or expert’s instructions to paste the ceramics onto your system.

When you need to repair part of the system, you can replace the required ceramics.

LCDM’s two-part epoxy resin and ceramic beads can also enable you to repair damaged parts in parts.

For a stronger bond, ask our team for vacuum bonding.

> > Natural firmness in contrast to the flexibility of polyurethane, ceramics have firmness.

LCDM’s ceramic lining system uses the natural durability of ceramics to protect the components of the flow system.

Each option has different types of wear resistance to keep the parts in good shape.

> > Environmental protection ceramics as a natural material.

LCDM pays attention to ecological customers and can regard ceramics as a green substitute for synthetic linings such as polyurethane.

Vacuum bonded ceramic wear-resistant lining LCDM team can use vacuum bonding to attach the ceramic lining to the user’s system.

LCDM uses the most advanced equipment to install ceramic wear-resistant bricks through vacuum bonding technology.

Through the vacuum bonding process, we can connect the ceramic lining to various custom designs.

Benefits of vacuum bonded lining > > improved performance: the vacuum bonding process can create one of the strongest ceramic bonding that can be obtained by Valley logistics dynamic equipment.

Through reliable engineering design, the impact resistance and wear resistance of the system can be enhanced..