This case analysis mainly introduces the problems and treatment methods that may be encountered in the design of steel structure.

1.

Use software sap2000v23 32.

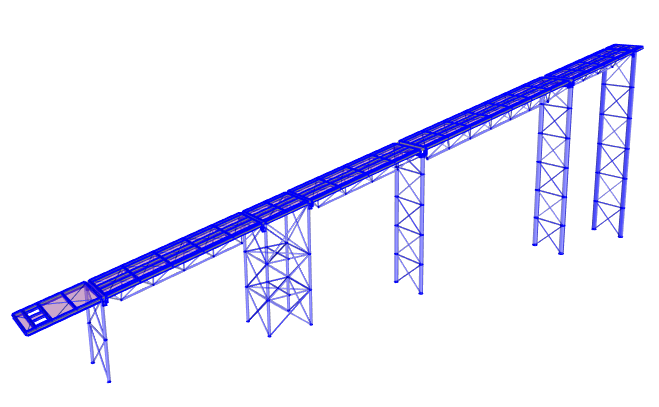

Model introduction the structure of a trestle is shown in Figure 1.

The member section adopts H-shaped section, and the steel structure is designed with new steel standard.

Figure 1 trestle 3 After the problem description design is completed, it is found that some members prompt “thin and flexible section” and some prompt “seismic thin and flexible”.

What are the meanings respectively? (a) thin and flexible section (b) seismic thin and flexible section figure 2 member overrun 4 Solution these two warning messages are related to the section width thickness ratio.

1.

The section is thin and flexible.

According to 3.5 of the new steel standard, the width thickness ratio of the section is divided into five grades: S1, S2, S3, S4 and S5.

For grade S5 sections, the web may buckle locally before the edge fibers yield, and the use of such sections should be avoided as far as possible.

When the width thickness ratio of the section plate is judged as S5, the program will give a warning of “thin and flexible section” and give a prompt of failure in the slendernesscheck item.

For H-section compression bending members, the checking calculation of web width thickness ratio and the stress ratio of web edge α About 0.

When α When 0 is taken as 2, it is the limit value of width thickness ratio of flexural members.

Fig.

3 when checking the width thickness ratio limit program, first judge the stress state of the member.

When the member is in tension (T), check it according to the flexural member.

At this time α 0 is always taken as 2, as shown in the section classificationparameters item.

When the member is compressed (c), press the bending member for checking calculation.

At this time, the program reads the stress value at the edge of the section (see table: elementstresses – frames for details) and calculates it according to 3.5.1 of the new steel standard α 0 and output relevant design details.

When the width thickness ratio exceeds the section limit of S4, the program judges the section grade as S5, as shown in Figure 6, and gives a warning.

Fig.

4 checking calculation of width thickness ratio of bending member Fig.

5 member stress diagram 6 checking calculation of width thickness ratio of bending member for this kind of warning, users can solve it from the following aspects: 1) select rolling section and check “rolling section” in the coverage item as “yes”.

At this time, the net height of web does not include the arc section at the transition of flange web plate, which can reduce the value of width thickness ratio; 2) Optimize the section by adjusting the section size and steel grade.

2.

Seismic thin and flexible section.

This information refers to that the width thickness ratio of the section exceeds the seismic limit.

For non seismic combinations, the program checks the width thickness ratio of various plates according to 7.3.1 of the new steel standard, and does not output the seismic limit value, as follows: Figure 7 checking the width thickness ratio of non seismic components.

For seismic combinations, the program will check whether the width thickness ratio of the section exceeds the seismic limit value, the beams and columns shall be implemented in accordance with 8.3.2 of the code of resistance, and the supports shall be implemented in accordance with the code of steel gb50011-2010 (2016 Edition).

This warning is given when the time limit is exceeded, and a prompt of failure is given in slendernesscheck.

Figure 8 checking calculation of width thickness ratio of seismic components if it is not necessary to judge the limit value of width thickness ratio for some components, check “ignore width thickness ratio checking” in the coverage item as “yes”, and the program will not judge such limit value at this time, The following figure: Figure 9 ignores the verification of width thickness ratio: Liu Huixuan recommends the stress averaging of [technical journal] shell element [technical journal] SAP2000 default steel plastic hinge verification example [technical journal] SAP2000 calculation scanning QR code of shrinkage and creep, Subscribe to technical journals review of previous issues [technical journal] SAP2000 API secondary development Python example [technical journal] comparison and analysis of normal section bearing capacity calculation of steel reinforced concrete members than [technical journal] steel members do not pass the stability check calculation.

Click to read the full text,.