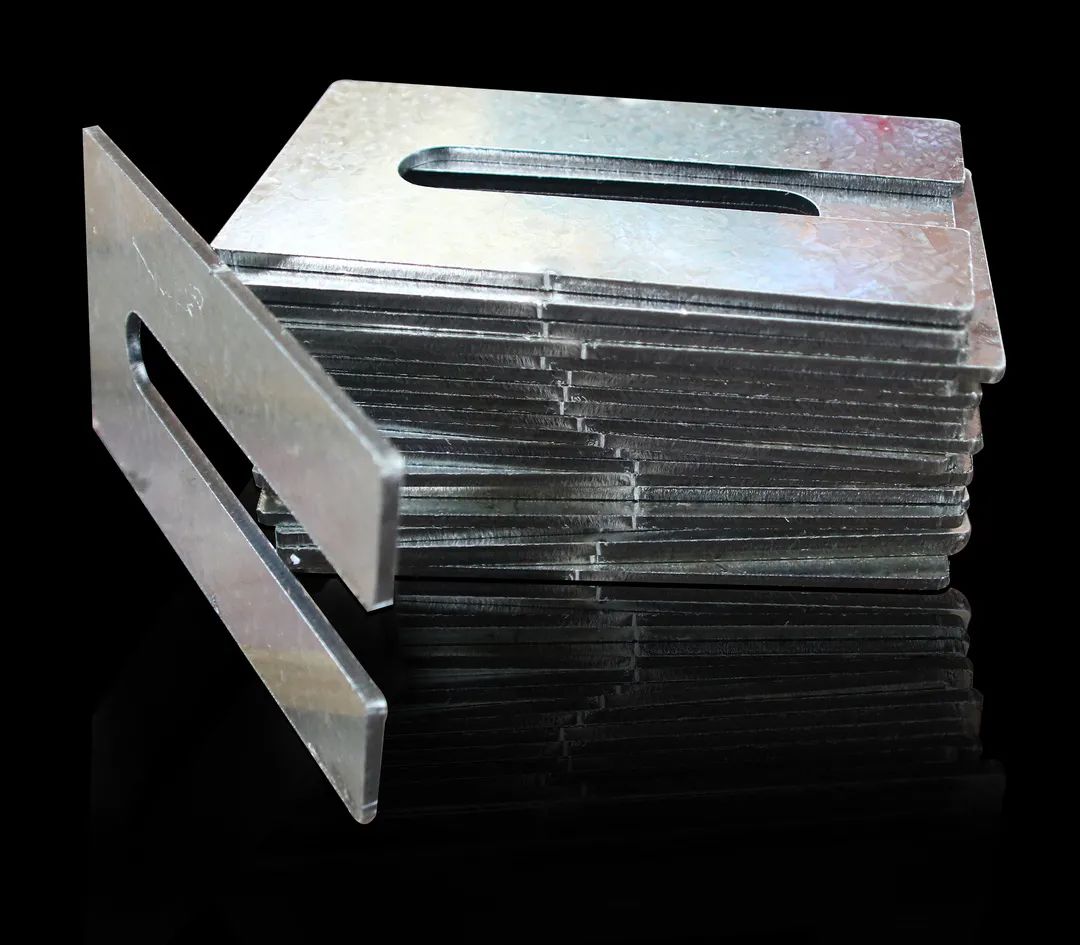

Before cutting, first understand the thickness category of the steel plate.

Secondly, we should adjust measures to local conditions and formulate cutting plans and methods in advance according to steel plates of different thicknesses.

In the actual operation, we should choose different cutting methods according to the thickness, material and other comprehensive conditions of the steel plate.

The last is water cutting, which has wide cutting range, high accuracy, not easy to deform and is more environmentally friendly, but it is slow and consumes a lot of energy.

If you want to become an excellent steel plate cutting master, you should carry out “specific problems and specific analysis” according to different situations and treat each steel plate cutting task seriously and efficiently! Shandong Sanwei Heavy Industry Co., Ltd.

However, when cutting steel sheet, it is easy to cause its deformation, the variety of cutting materials is limited, and the technical requirements are relatively higher.

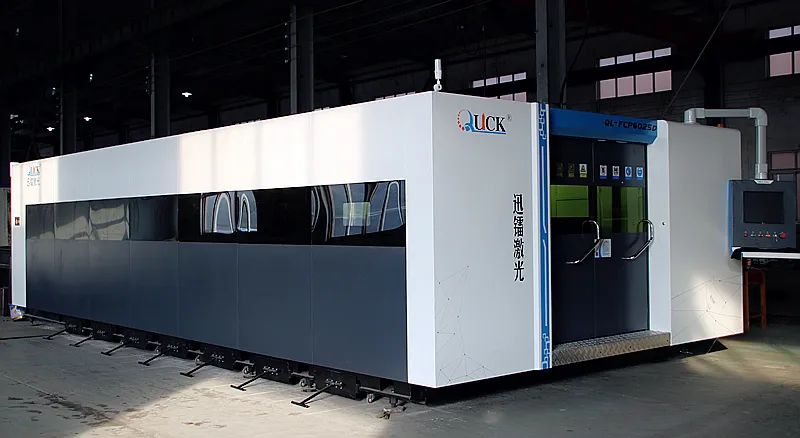

The machine runs stably and has high positioning accuracy; By using laser cutting, the laser pipe cutting machine can realize the cutting of metal components with high precision, multi process and high efficiency, and can carry out the cutting and drilling of square and round pipes, cutting and drilling of special-shaped pipes and other processing processes; Steel plate cutting is usually divided into two categories: cold cutting treatment and hot cutting treatment.

It is used for cutting large, medium and small plates of various special-shaped carbon steel, manganese steel, stainless steel and other metal materials.

In cold cutting, ordinary shear method or water flow cutting method is generally used; Flame cutting, plasma cutting or laser cutting can be used for thermal cutting treatment.

The thickness of steel plate is the main reason affecting the cutting of steel plate.

According to the different thickness, the steel plate can be divided into thin plate (0.2mm-4mm), medium plate (4mm-60mm) and thick plate (> 60mm).

has 80000 square meters of production workshops and more than 200 sets of intelligent production equipment.

We can choose to cut according to the situation.

At present, the commonly used cutting machines are: optical fiber NC cutting machine, NC plasma cutting machine, laser pipe cutting machine, etc; Optical fiber numerical control cutting machine has the characteristics of high speed, high precision and high adaptability.

However, the precision of laser cutting is very high, which can meet the needs of some customers with high accuracy requirements.

For example, when cutting these regular steel sheets into rectangles and triangles, you can choose the plate shear, which not only has high speed, guaranteed quality, but also low cost.

In short, several common methods of steel plate cutting, like the martial arts scripts of different sects, have their own advantages and disadvantages.

Pay attention to us , share more knowledge of steel structure processing , steel components in industrial production carry out a variety of cutting and processing of steel according to process needs.

In addition to cutting by plate shears, the cost of flame cutting is not high, and the operation is more flexible and free, and different shapes of steel plates can be cut.

It can cut special-shaped parts, blank parts, embedded plates, steel plate longitudinal cutting, cutting blocks, punching, bending and other processing processes according to the requirements of customers’ product drawings.

How to cut steel plates with different thickness.

It uses high-power density laser beam to irradiate the cut materials to realize thermal cutting of materials, and can accurately cut raw materials of various materials, specifications, thicknesses and fineness; CNC plasma cutting machine is an automatic equipment for thermal cutting of high-precision steel plate.

It can realize mass production, ensure product quality, save processing costs and realize rapid delivery…

The cost of laser cutting is relatively high, because the price of one laser cutting equipment is higher than that of other equipment, so the cost will be increased relatively.

In the case of oxygen addition, laser cutting can meet the cutting of steel plate with thickness of 20mm.