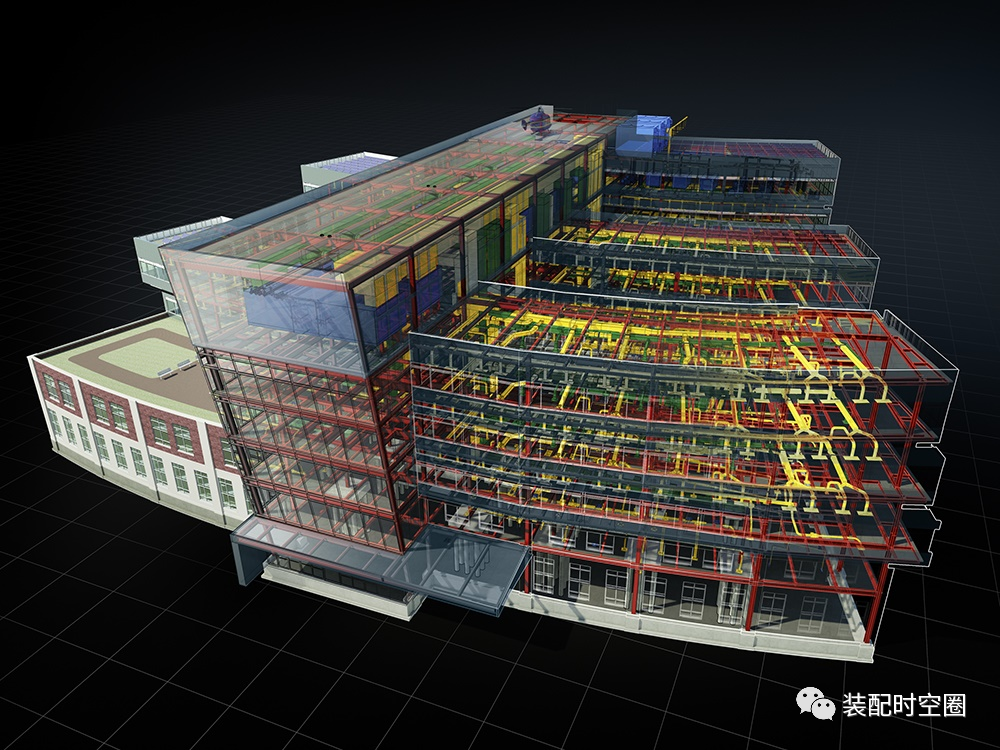

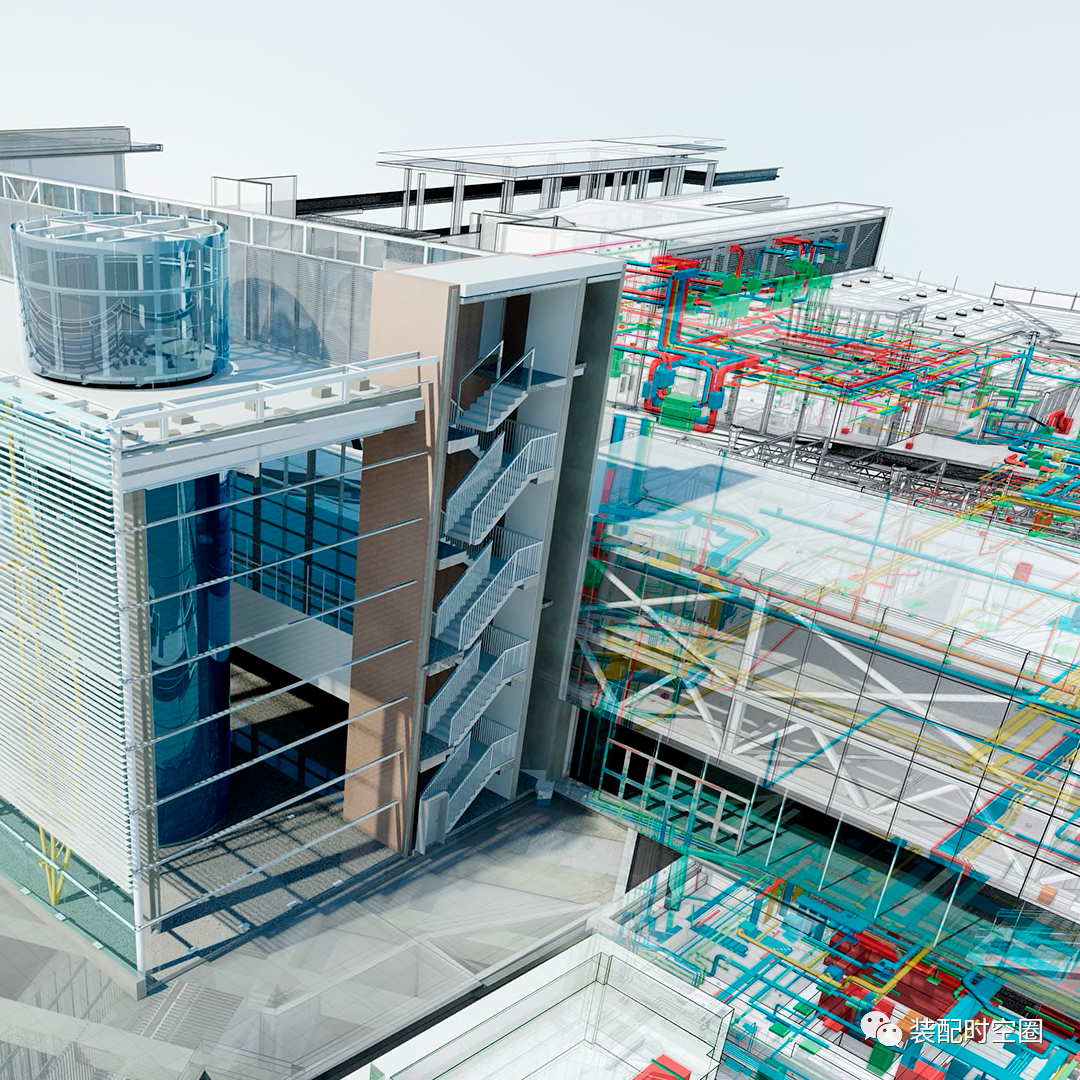

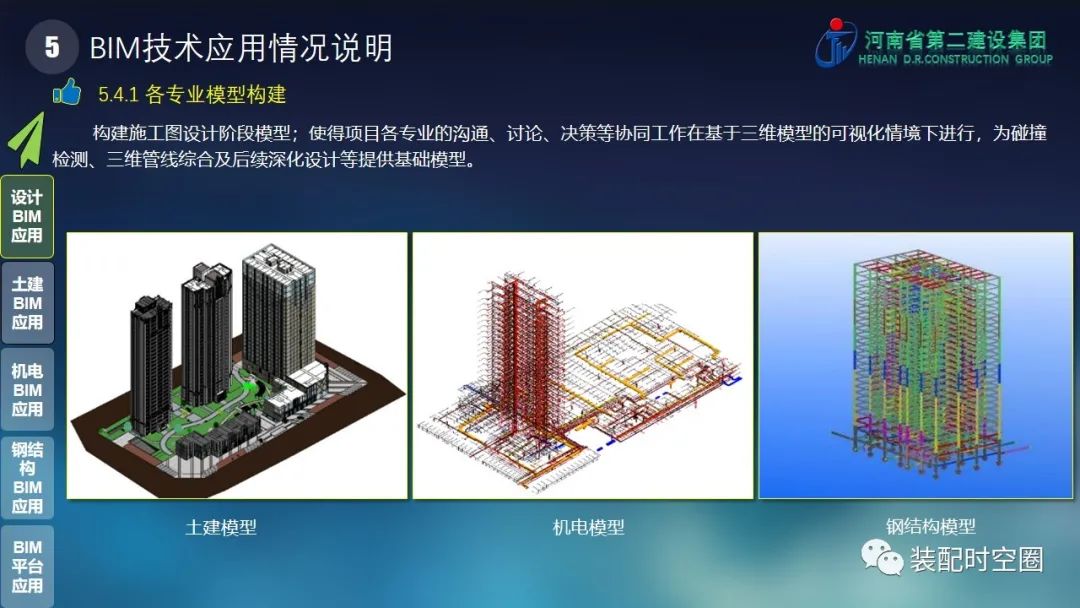

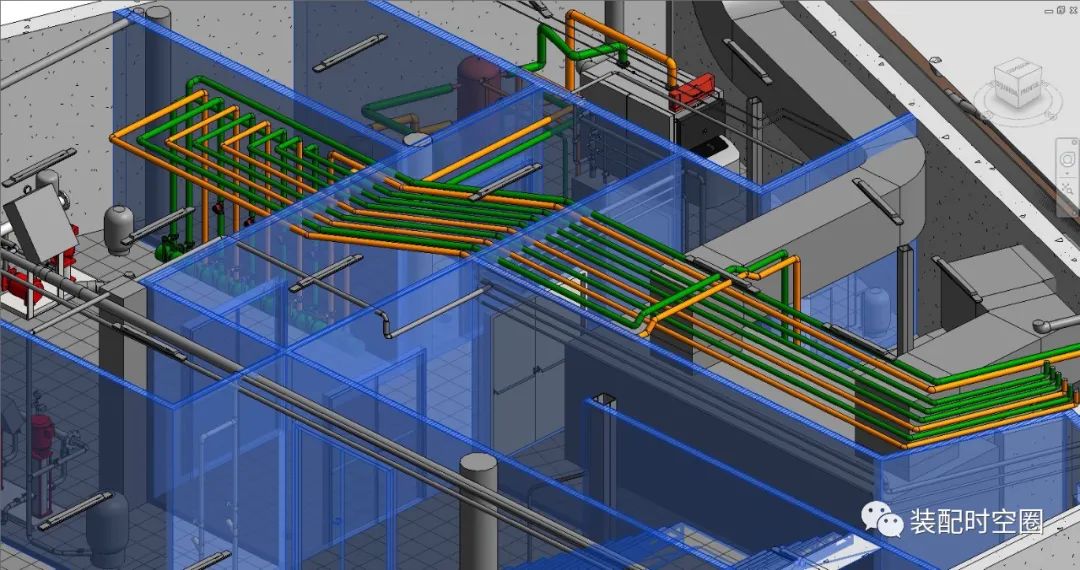

Hanging plate connector design and construction drawing design stage model; Make the communication, discussion, decision-making and other collaborative work of various disciplines of the project be carried out in the visual context based on the three-dimensional model, so as to provide a basic model for collision detection, three-dimensional pipeline synthesis and subsequent deepening design.

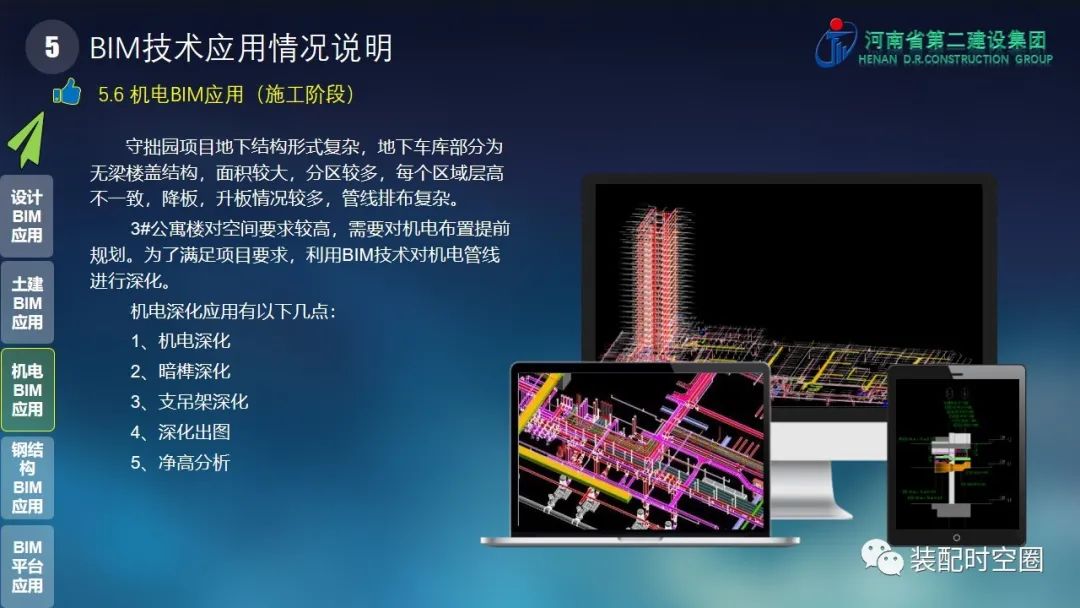

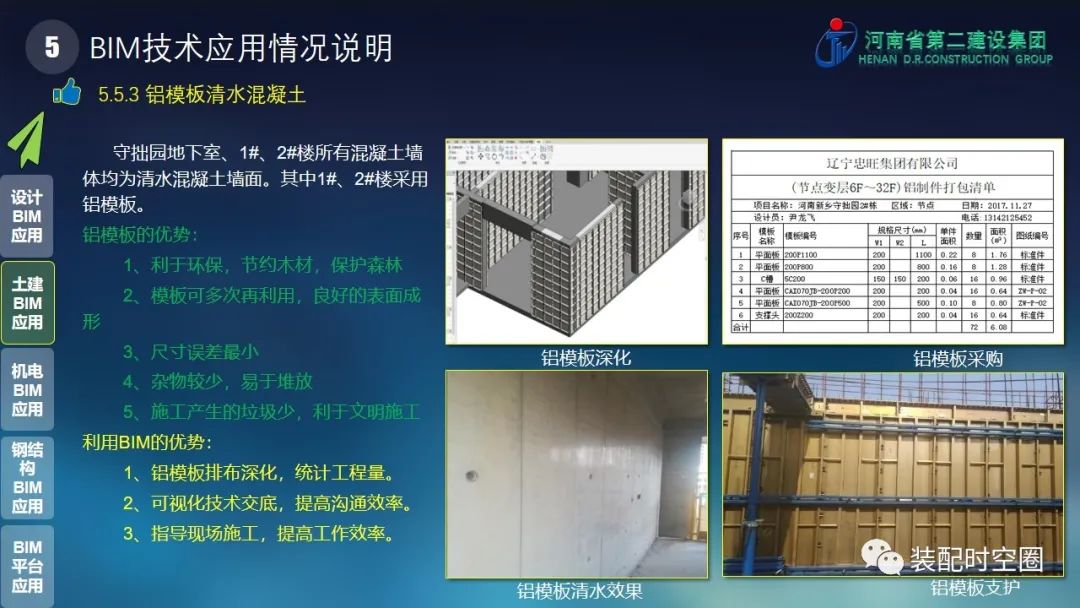

All management should play a demonstration and leading role in Henan and even the whole country; A variety of new technologies are adopted in the project, including fair faced concrete, aluminum formwork, concrete assembly and steel structure assembly; The underground garage adopts beamless floor, with many elevations and complex electromechanical pipelines; The construction period of the project is tight, there are many participants, there are many cross information among disciplines, and it is difficult to coordinate; Fair faced concrete is used in the project, and the formwork layout is complex.

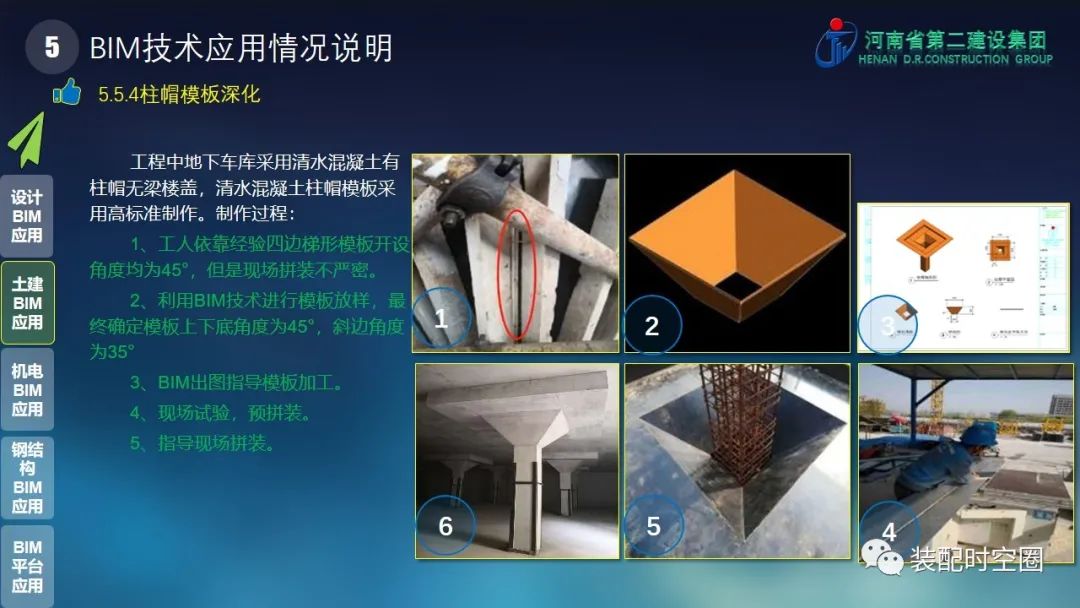

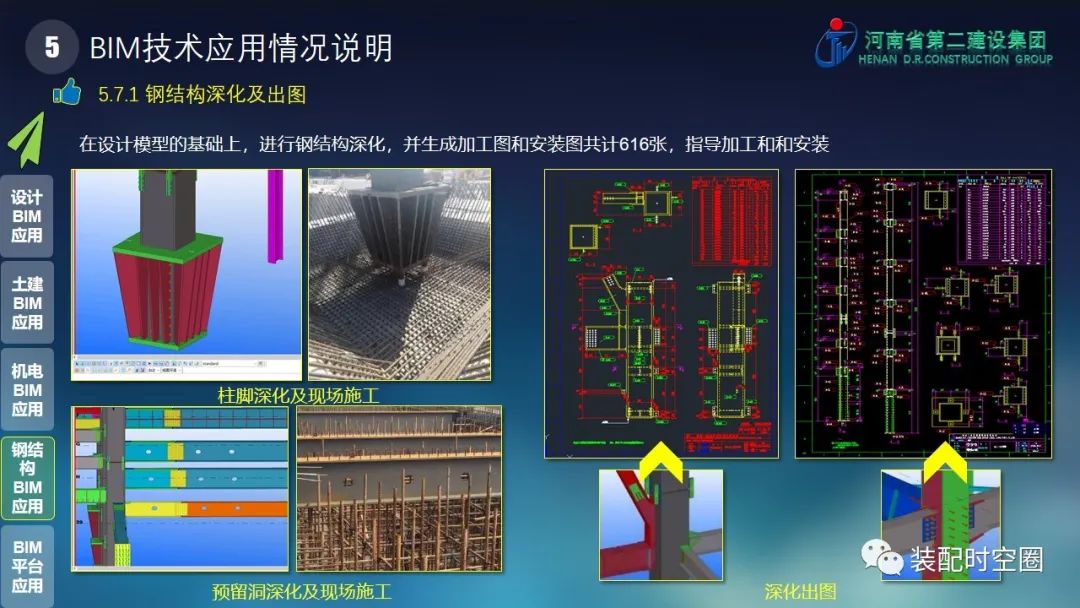

Column cap formwork deepening 5.

Floor tile layout 9.

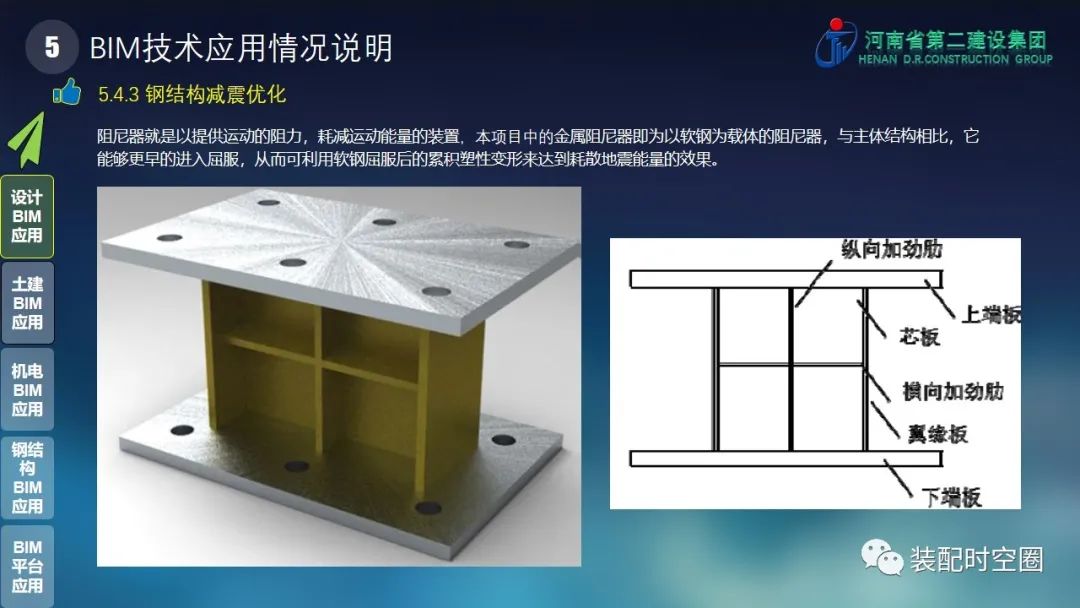

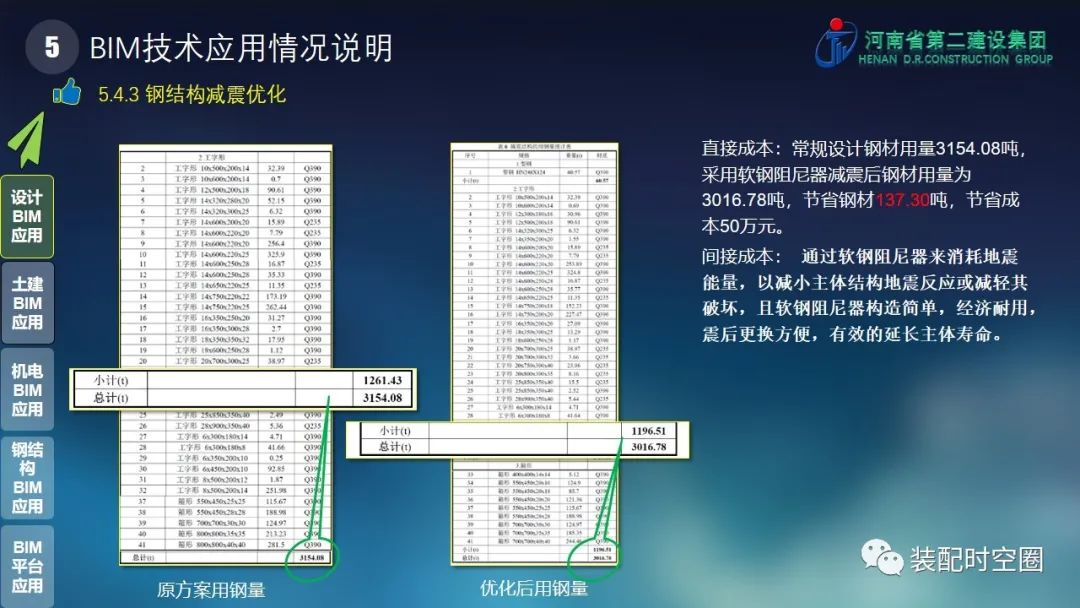

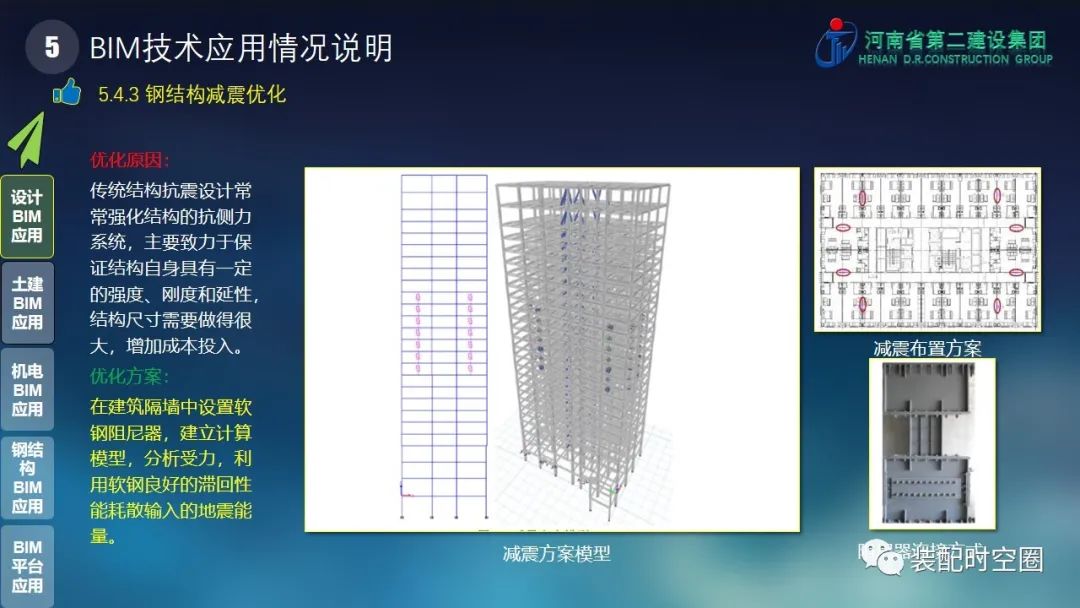

Optimization scheme: set mild steel damper in the building partition wall, establish the calculation model, analyze the stress, and use the good hysteretic performance of mild steel to dissipate the input seismic energy.

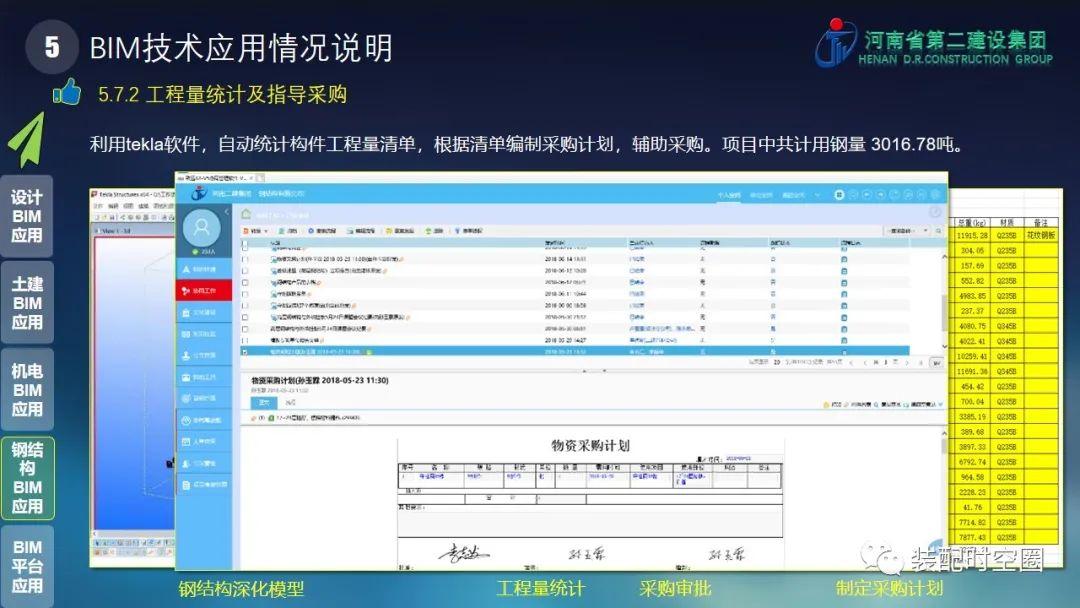

The participating units mainly include 5 units: Design Institute, steel structure company, Jingmei curtain wall company, Qingshui technology company and construction general contractor.

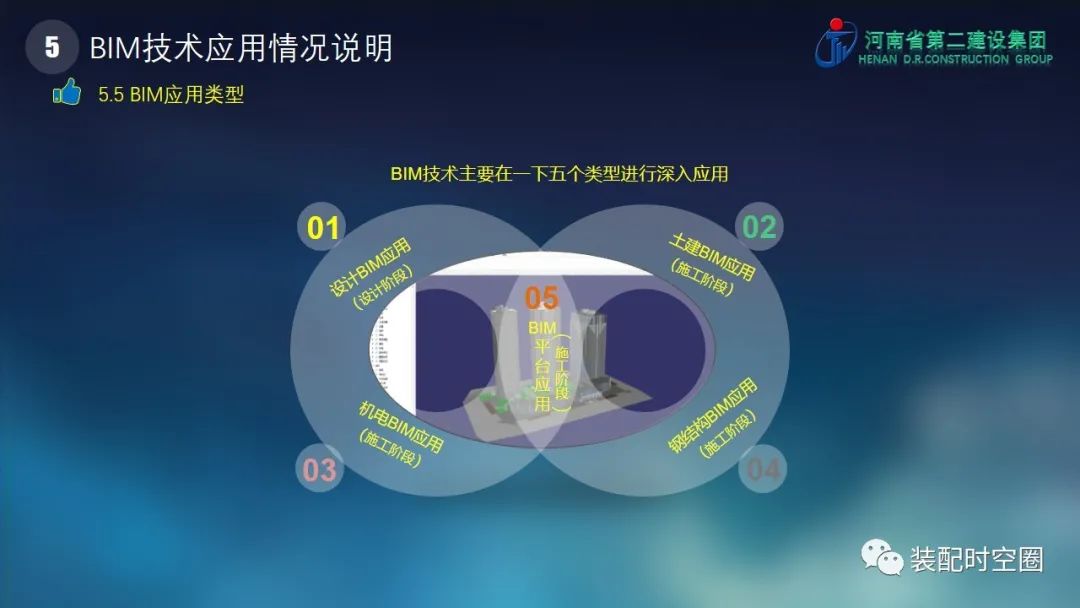

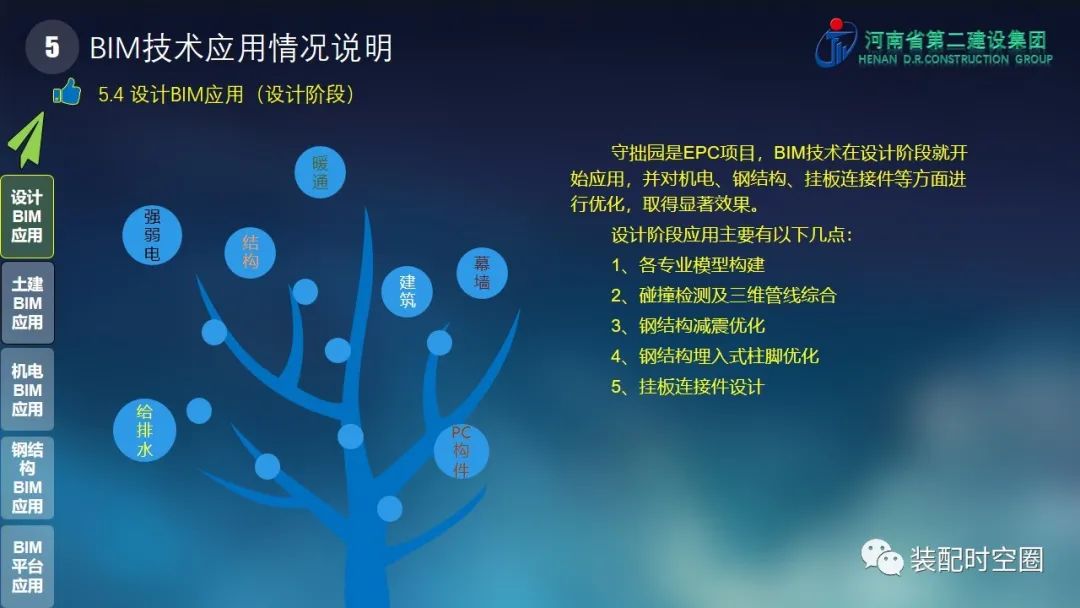

The main applications in the design stage are as follows: 1.

By setting up corresponding processes, the process dynamics can be monitored from time to time, and the dynamic process can be checked.

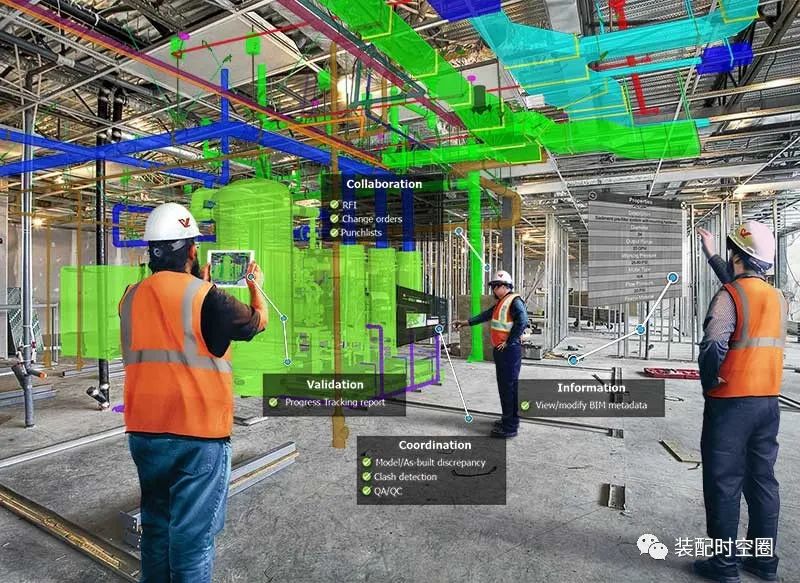

After receiving the problem message, the engineering problem docking personnel enter the site to deal with the problems to be solved, and then reply on the Yunping platform.

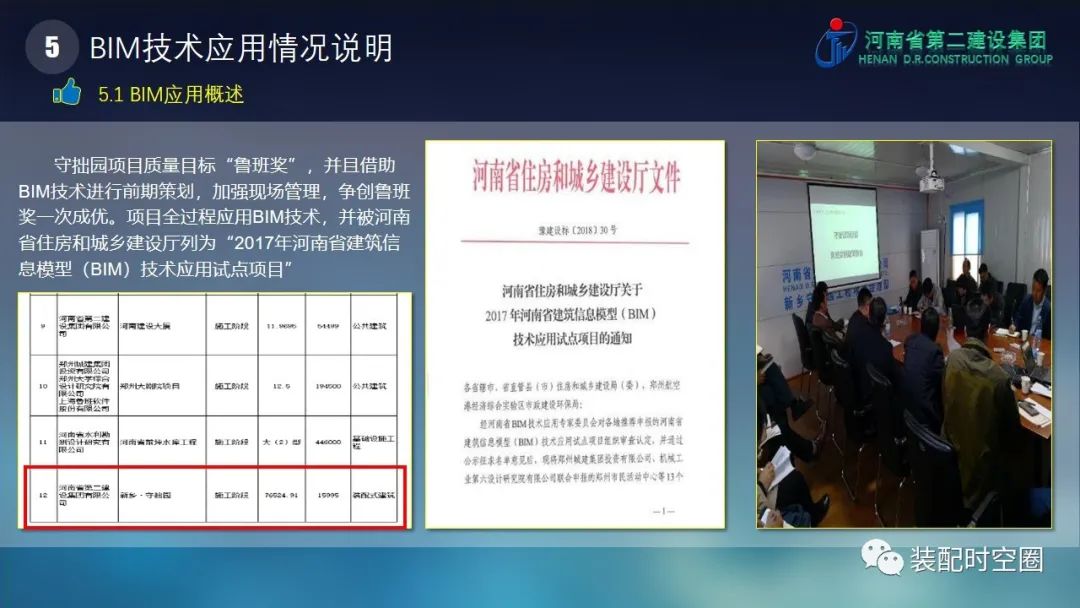

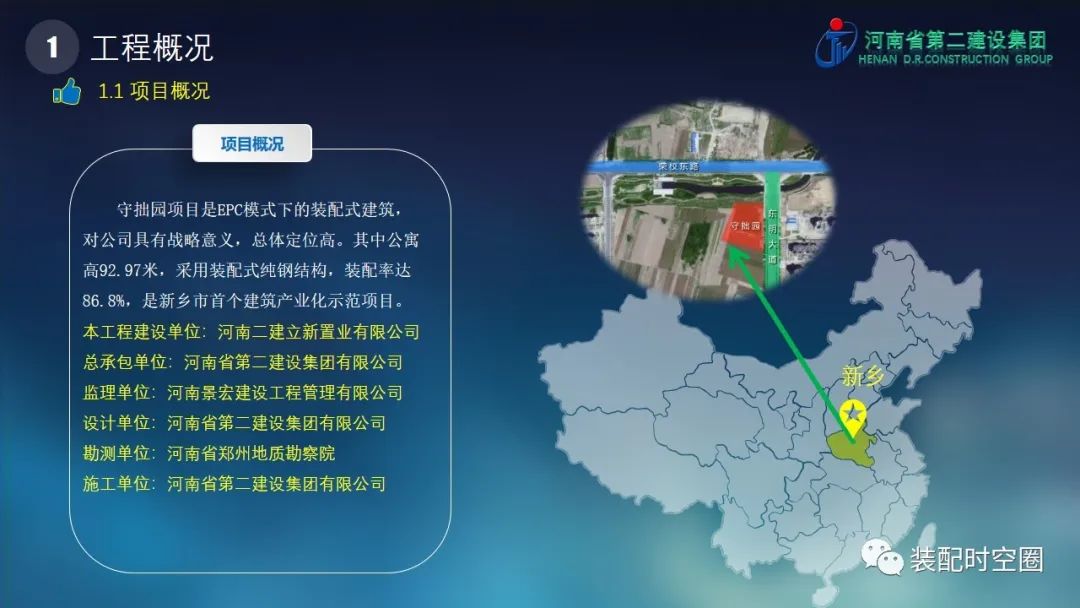

Shouzhuoyuan is an EPC project.

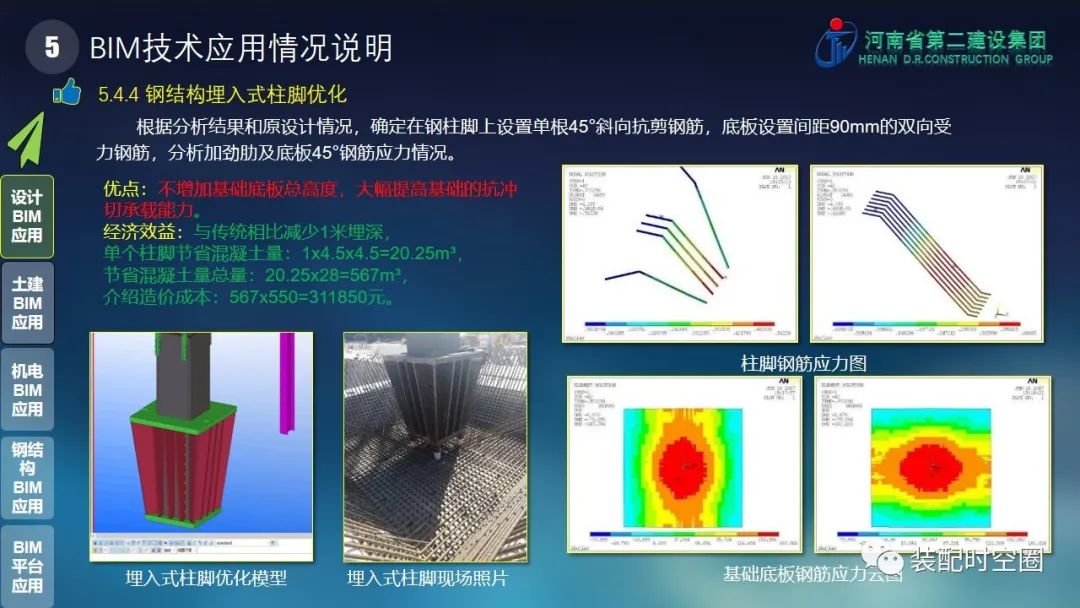

5=20.25m ³, Total amount of concrete saved: 20.25×28 = 567m ³, Introduction cost: 567×550 = 311850 yuan.

BIM technical difficulties and key analysis of the project: the project goal is high and the project positioning is high.

According to the analysis results and the original design, it is determined to set a single 45 ° oblique shear reinforcement on the steel column base, and set two-way stressed reinforcement with a spacing of 90mm on the bottom plate, and analyze the stress of stiffener and 45 ° reinforcement on the bottom plate.

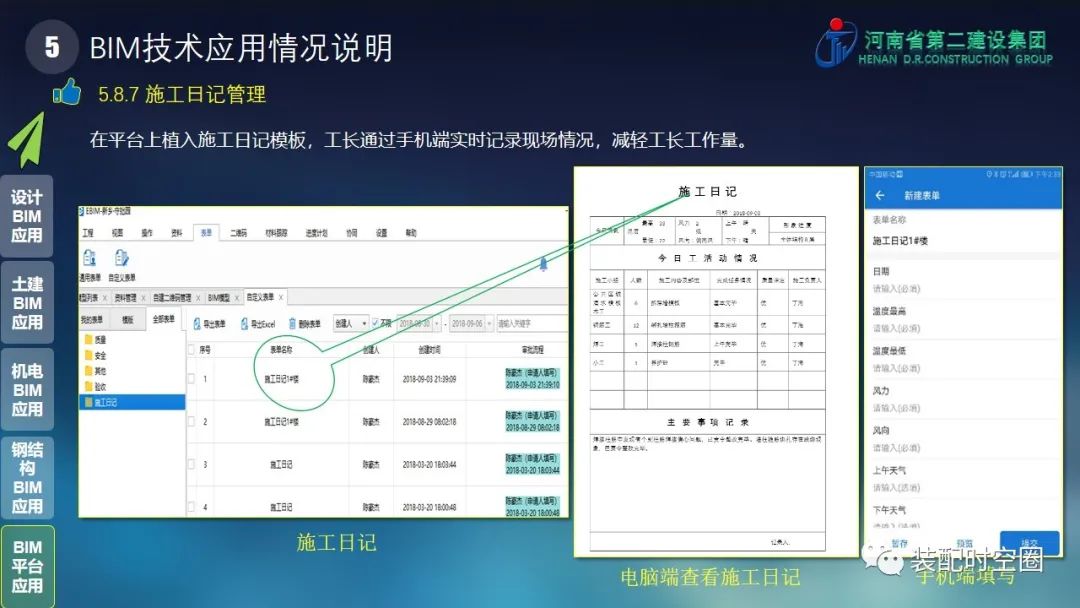

The construction diary template is implanted on the platform, and the foreman records the site situation in real time through the mobile terminal to reduce the workload of the foreman.

Advantages: the total height of the foundation slab is not increased, and the punching bearing capacity of the foundation is greatly improved.

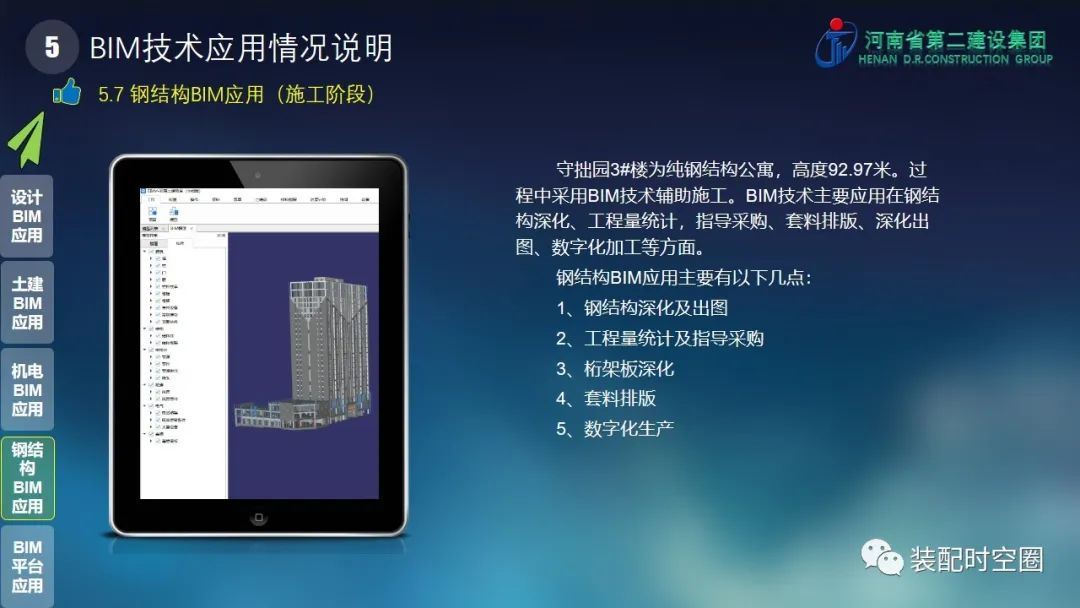

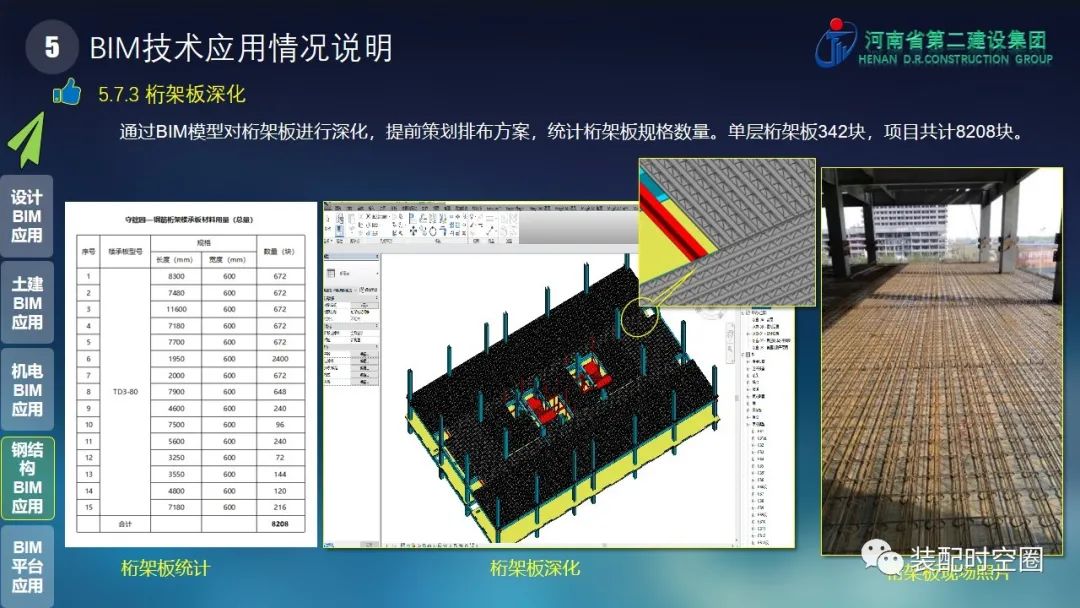

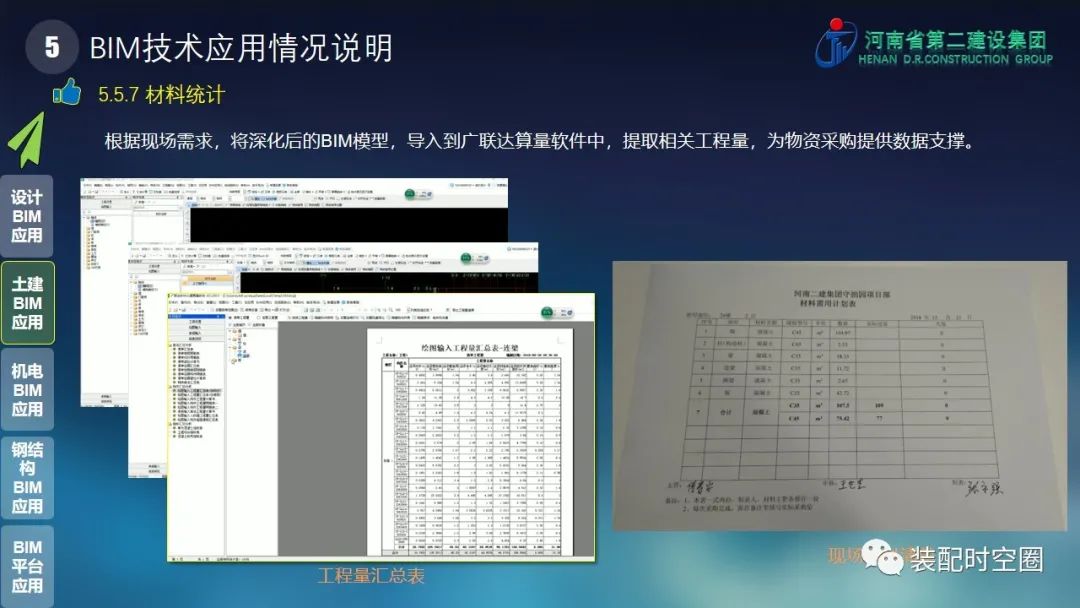

Material statistics 8.

The mild steel damper has the advantages of simple structure, economy and durability, convenient replacement after earthquake, and effectively prolongs the service life of the main structure.

Finally, big data analysis can be carried out through the platform.

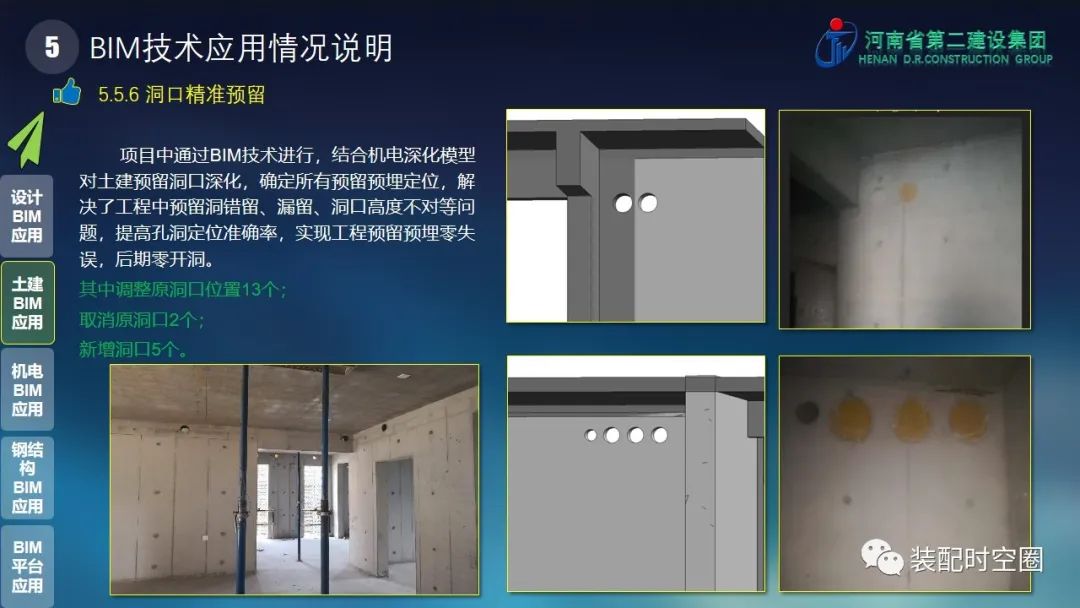

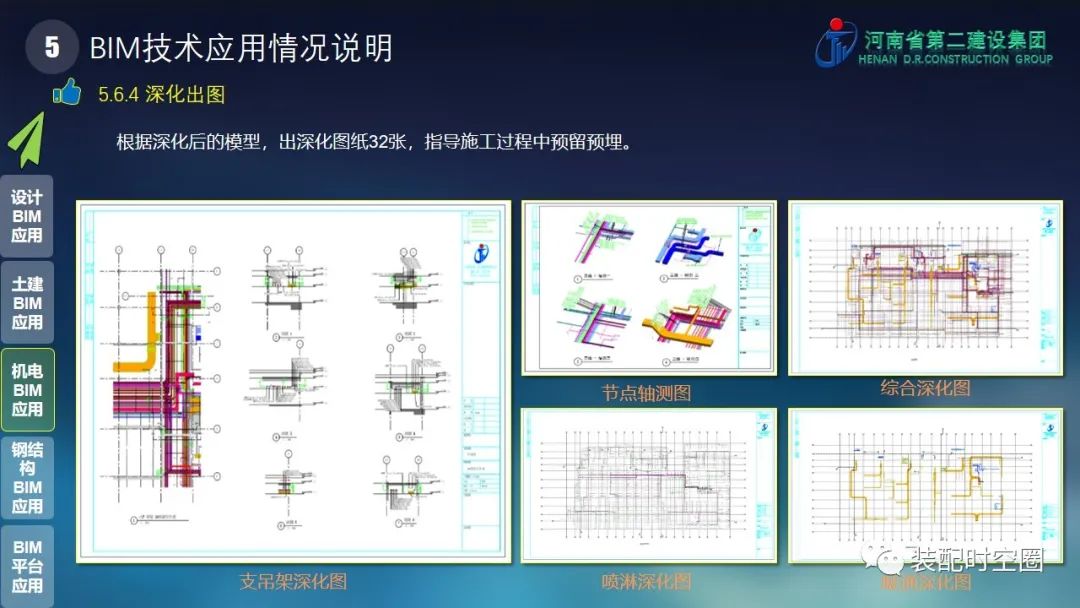

Accurate reservation of openings 7.

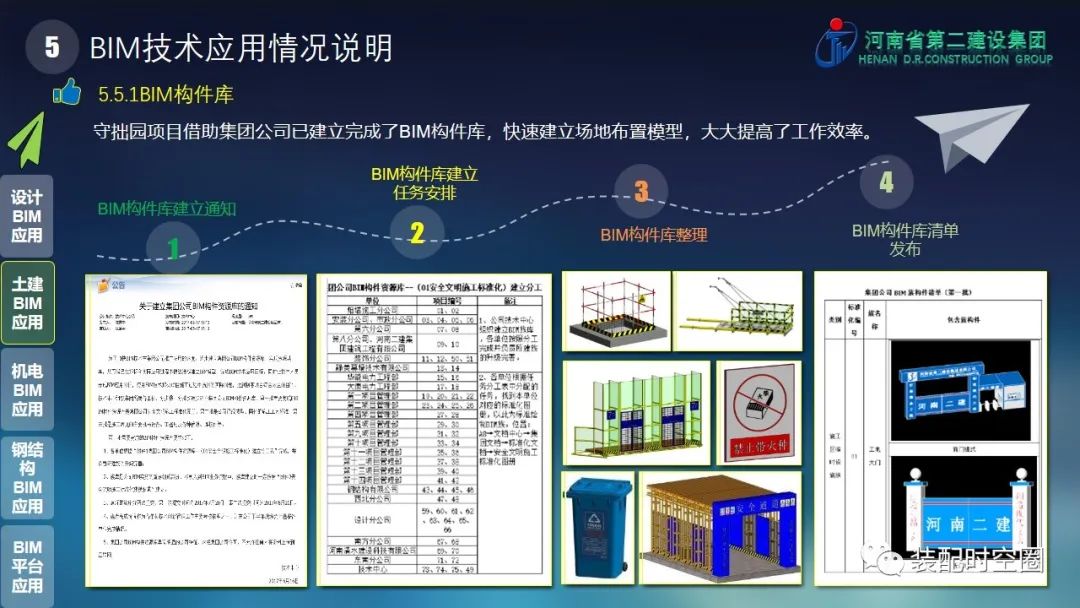

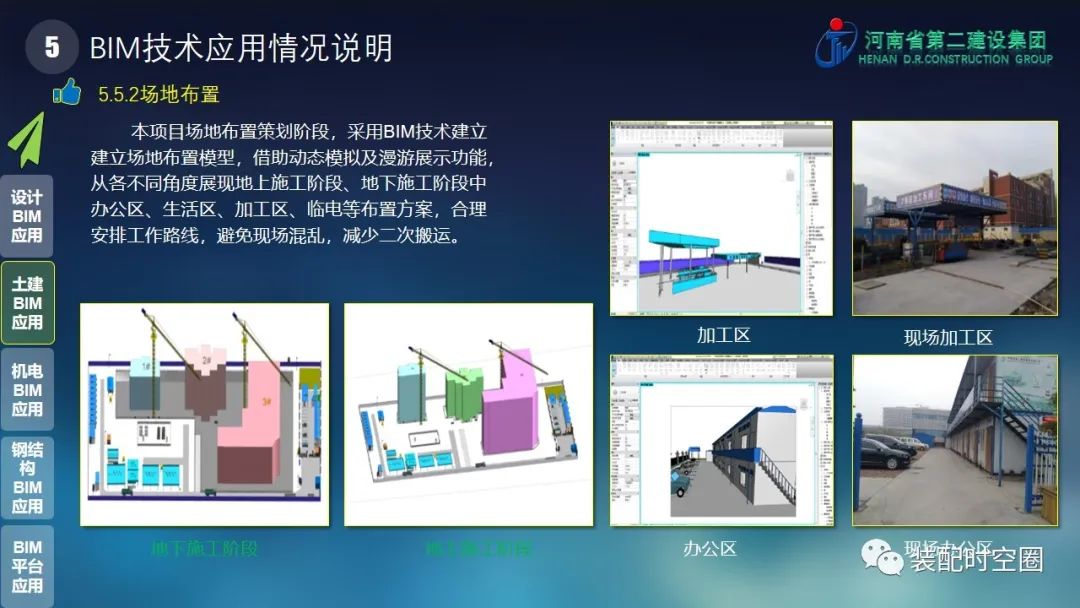

In the site layout planning stage of the project, BIM Technology is used to establish the site layout model, With the help of dynamic simulation and roaming display function, the layout schemes of office area, living area, processing area and temporary power supply in the above ground construction stage and underground construction stage are displayed from different angles, and the work route is reasonably arranged to avoid on-site confusion and reduce secondary handling.

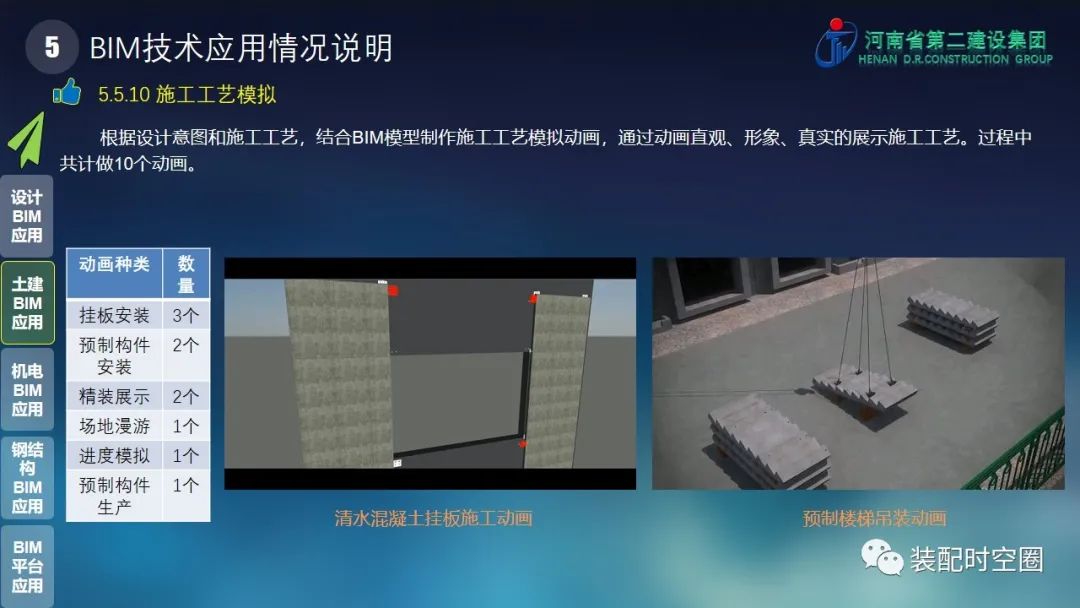

Construction process simulation.

Economic benefits: compared with the traditional construction method, the buried depth is reduced by 1m, and the concrete quantity of a single column base is saved: 1×4 5×4.

Shock absorption optimization of steel structure 4.

The structural size needs to be made very large and the cost investment needs to be increased.

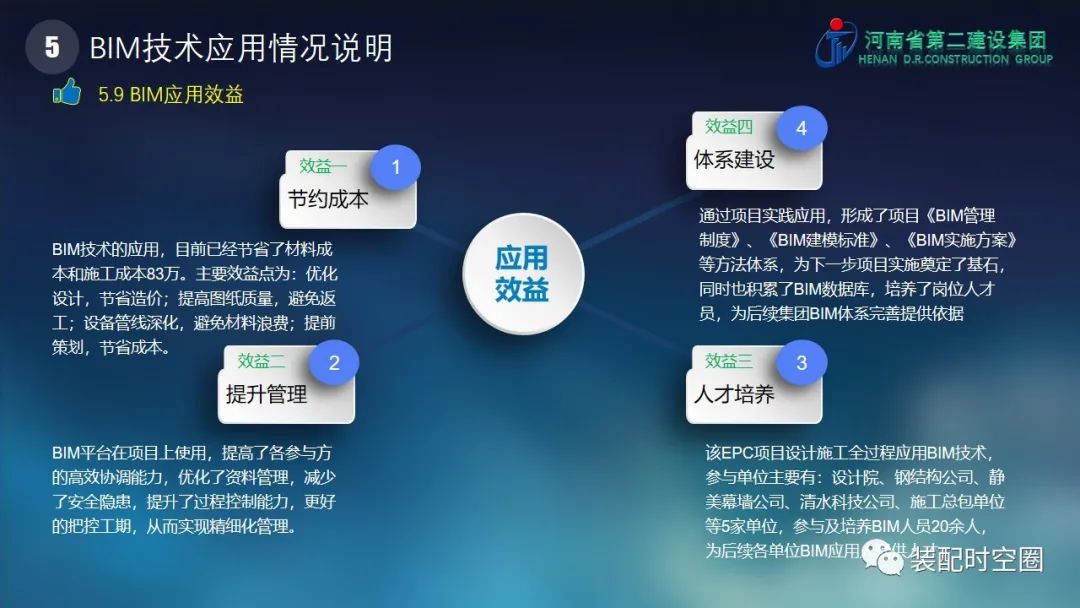

At the same time, it has also accumulated the BIM database and trained post talents, so as to provide the basis for the improvement of the BIM system of the follow-up group…

Model construction of various disciplines 2.

Decoration model room planning 10.

The application of BIM Technology has saved 830000 material costs and construction costs.

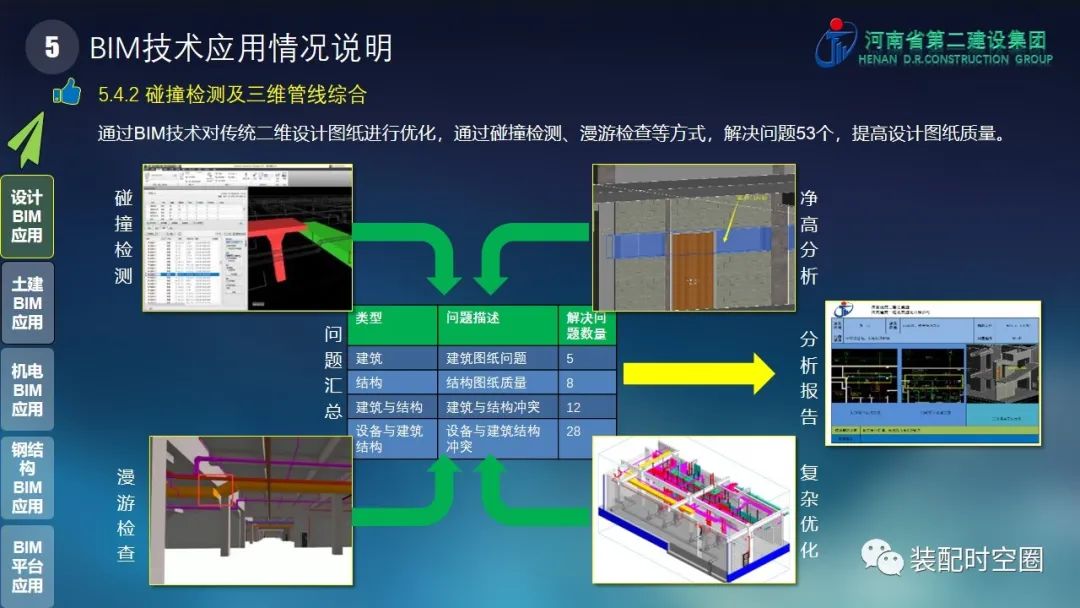

The traditional two-dimensional design drawings are optimized through BIM Technology, 53 problems are solved through collision detection and roaming inspection, and the quality of design drawings is improved.

Aluminum formwork fair faced concrete 4.

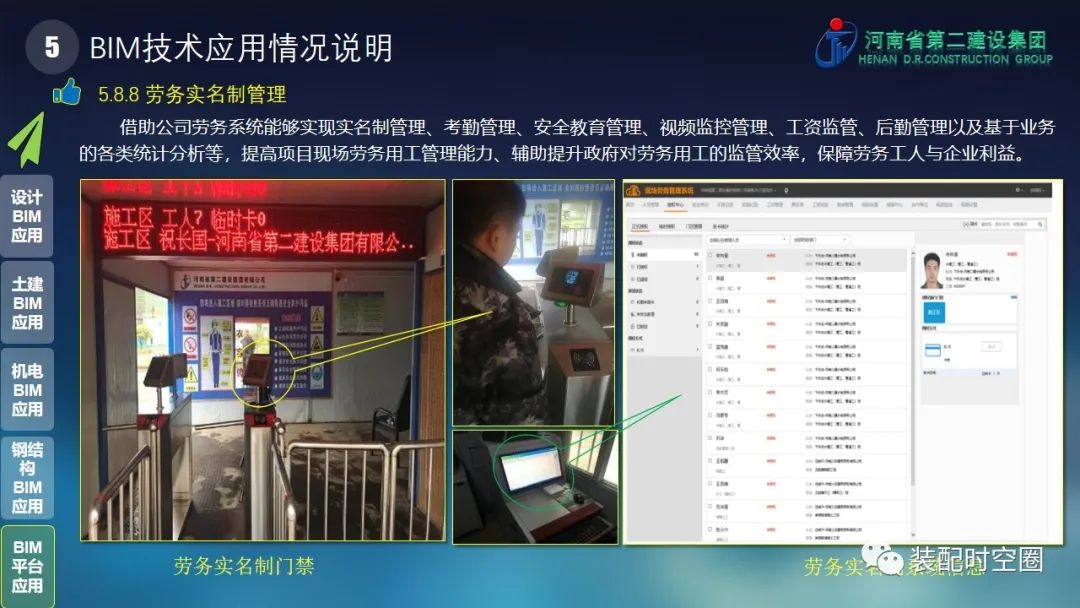

With the help of the company’s labor system, it can realize real name management, attendance management, safety education management, video monitoring management, wage supervision, logistics management and various statistical analysis based on business, improve the management ability of labor employment on the project site, assist in improving the government’s supervision efficiency of labor employment, and protect the interests of labor workers and enterprises.

The quality and safety of the site is managed through the BIM platform.

BIM construction library 2.

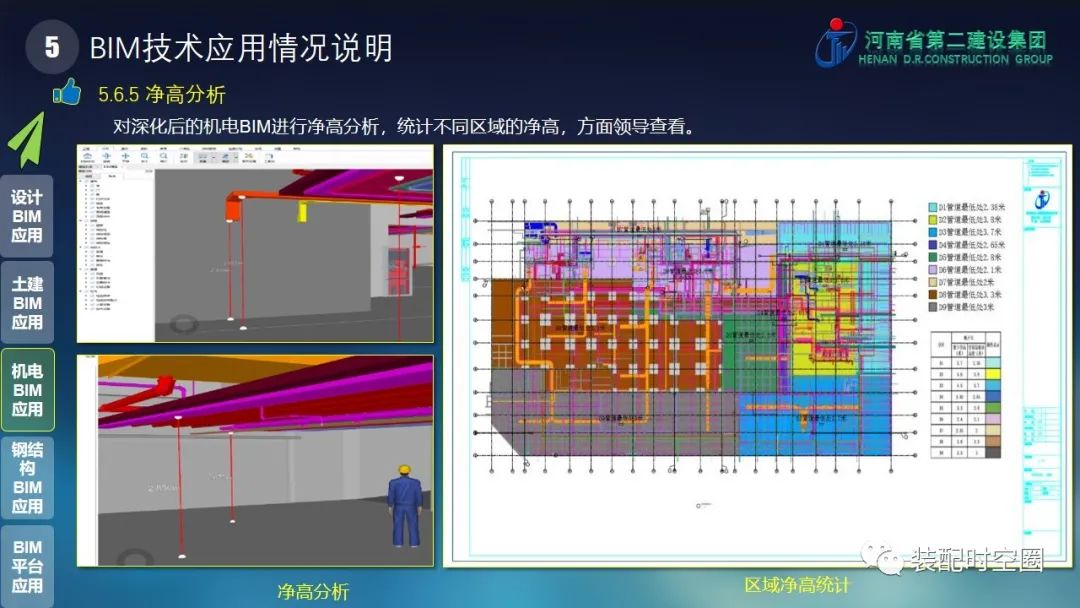

BIM Technology has been applied in the design stage, and has optimized Electromechanical, steel structure, hanging plate connectors and other aspects, and achieved remarkable results.

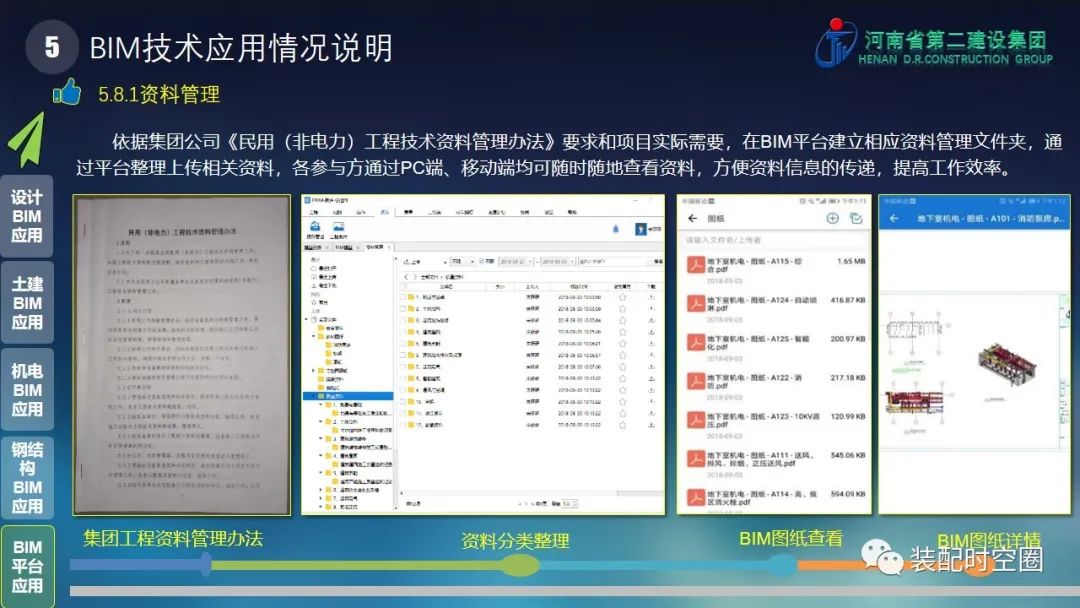

Establish a project dynamic circle through the platform, and all participants can understand the project situation in time.

More than 20 BIM personnel are involved and trained to provide talents for BIM applications of subsequent units.

The problem can be traced back to the specific person in charge, avoiding prevarication in the later stage.

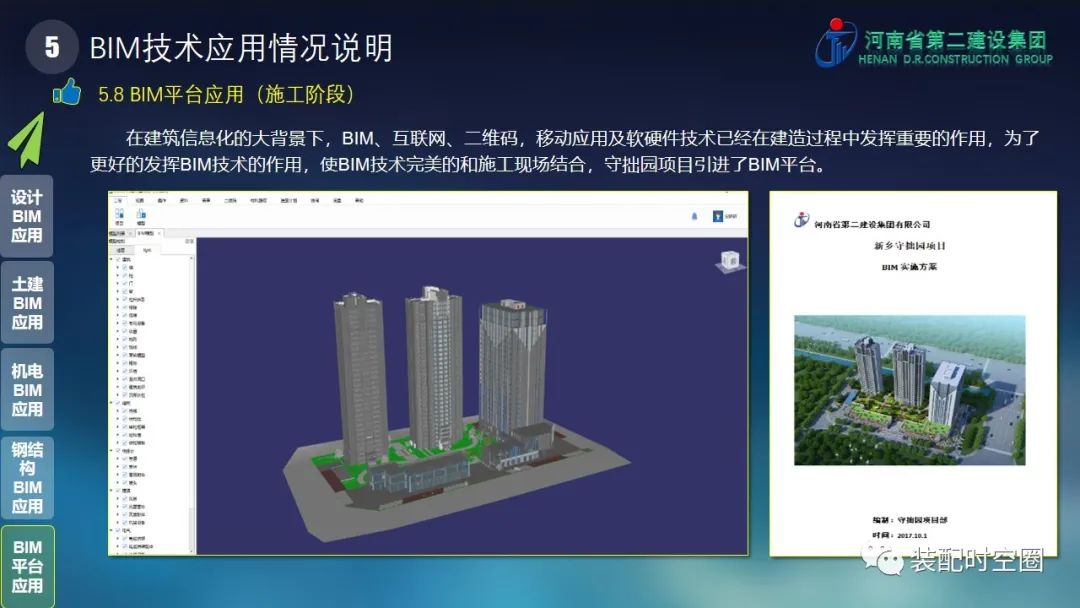

The use of BIM platform in the project improves the efficient coordination ability of all participants, optimizes data management, reduces potential safety hazards, improves process control ability, and better controls the construction period, so as to realize fine management.

Optimization reason: the traditional structural seismic design often strengthens the lateral force resistance system of the structure, which is mainly committed to ensuring that the structure itself has certain strength, stiffness and ductility.

The main benefit points are: optimize the design and save the cost; Improve drawing quality and avoid rework; Deepening of equipment and pipelines to avoid material waste; Plan in advance to save costs.

Civil BIM application mainly includes the following points: 1.

Embedded column base optimization of steel structure 5.

BIM Technology is applied in the whole process of design and construction of the EPC project.

Site layout 3.

Direct cost: the conventional design steel consumption is 3154.08 tons, and the steel consumption after damping with mild steel damper is 3016.78 tons, saving 137.30 tons of steel and 500000 yuan.

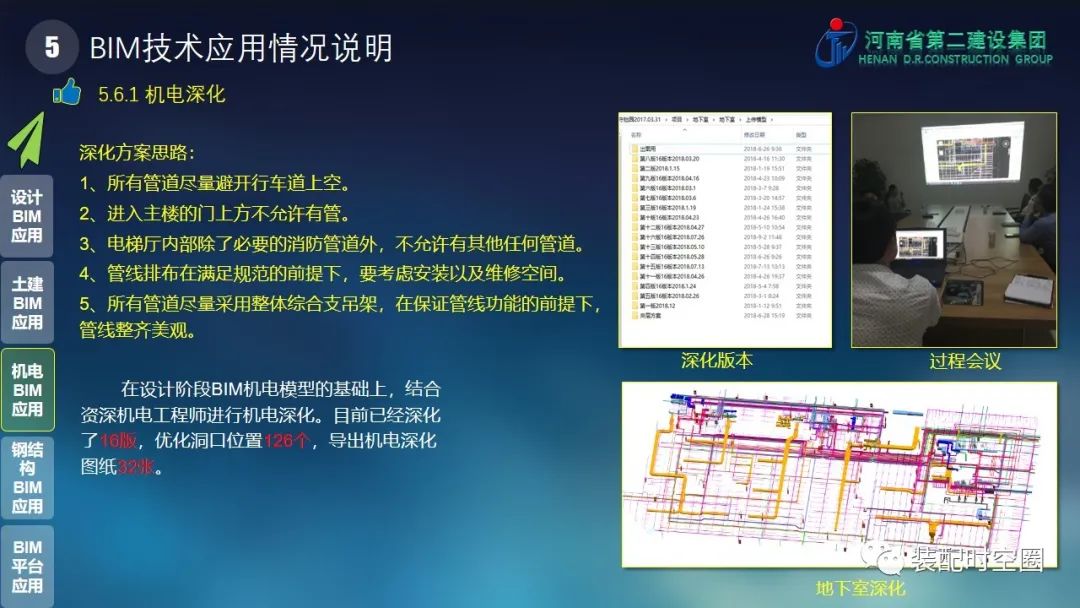

Collision detection and three-dimensional pipeline synthesis 3.

Through the practical application of the project, the project has formed the BIM management system, BIM modeling standard, BIM implementation scheme and other method systems, which has laid the foundation for the next project implementation.

Manage on-site form process approval documents through BIM platform.

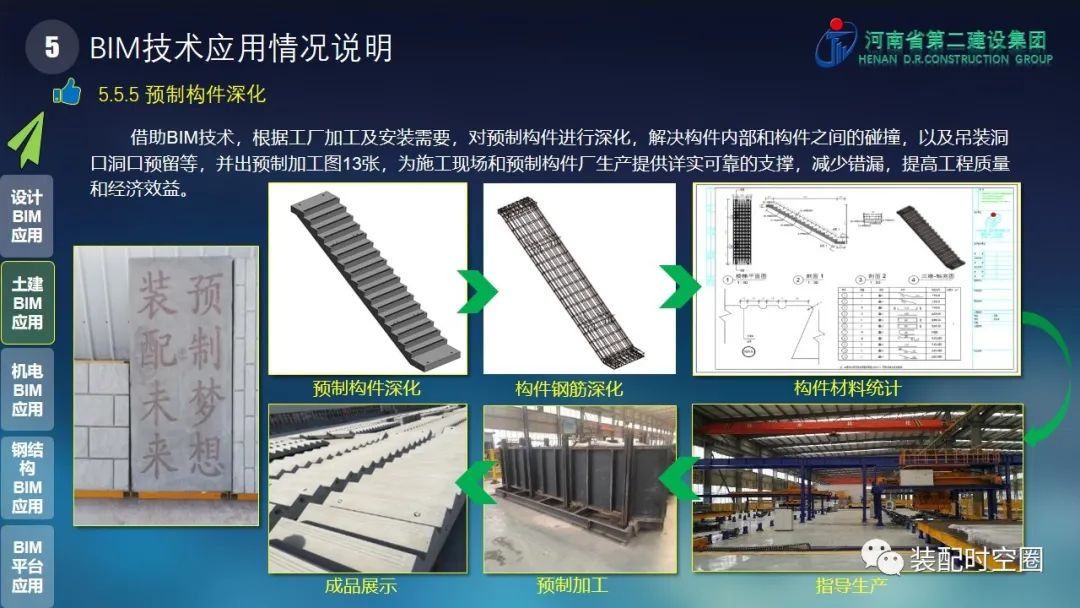

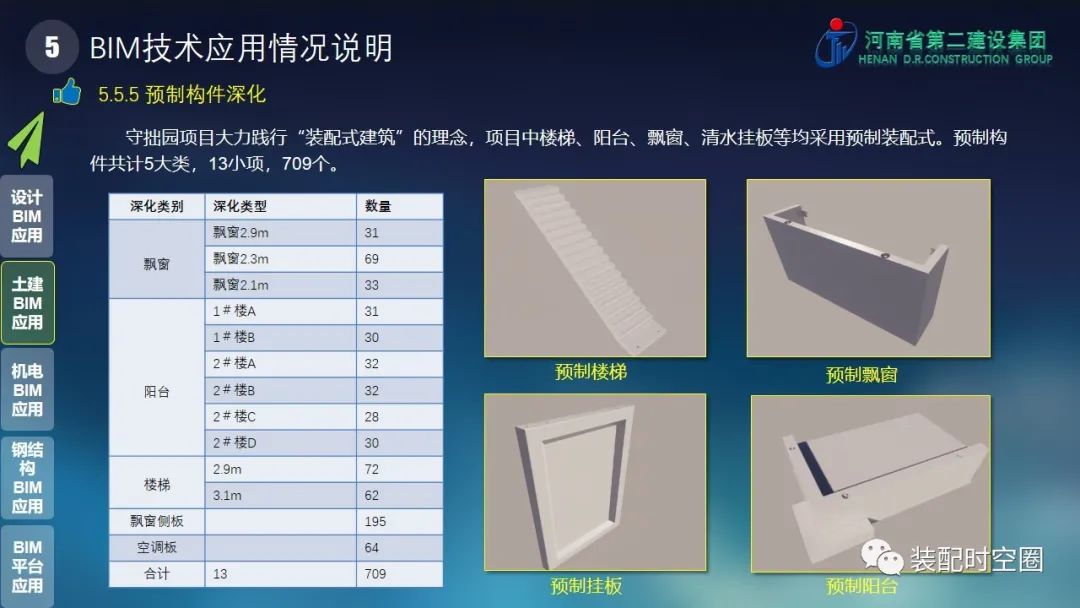

Prefabricated component deepening 6.

Indirect cost: the mild steel damper consumes seismic energy to reduce the seismic response or damage of the main structure.

It needs to be planned in advance to achieve one-time optimization in the process; 92.97m, high-purity steel structure apartment, with great construction difficulty.

After entering the site, the on-site engineering personnel send mobile problems for the on-site operations that do not meet the requirements.