The survey results show that the market scale of prefabricated components of municipal infrastructure is large, the degree of standardization is high, and the product quality is good.

The prefabricated component product system of municipal infrastructure includes prefabricated pipe gallery, prefabricated bridge, prefabricated segment, prefabricated drainage pipeline, etc.

▲ click the picture to sign up for the engineering teachers’ conference.

The price competition is mainly to solve the business problem of more monks and less porridge, which is also the survival and development problem faced by most prefabrication factories.

Generally, the wage cost of labor outsourcing is lower than that of their own employees, In addition, the “five insurances and one fund” can be delivered according to lower standards, and the overall explicit cost is lower.

The labor cost accounts for an increasing proportion in PC components.

The rise of market prices is in line with the law of macroeconomic development and the general mentality of the market at this stage.

From the current production management level of enterprises, the overall production efficiency is not much different.

This questionnaire mainly includes geographical location, equipment, labor, product quality, 2021 production and operation, and the influencing factors of the company’s development.

Overall, this questionnaire mainly includes geographical location, equipment, labor, product quality, production and operation in 2021, and influencing factors of the company’s development.

This not only means that the factory has steam curing conditions, but also shows that the proportion of components produced by steam curing is high, and the factory is basically full load production.

Through investigation and analysis, due to tight time, heavy tasks, improper management and other reasons, prefabricated component factories have encountered problems such as appearance quality, dimensional deviation, reserved hole blockage and so on, resulting in quality defects in some finished prefabricated components in the factory, affecting the overall quality of prefabricated buildings.

The number of PC prefabricated component manufacturers has increased rapidly, and the product price has stabilized.

This paper briefly analyzes and summarizes the survey data.

Due to the increase in the number of prefabricated enterprises and the difference in raw materials and labor costs, the price competition is very fierce, and the actual price is generally 20% ~ 30% lower than the market guide price.

The wages and welfare benefits of self owned workers are higher.

To a certain extent, it increases the uncertainty of supply and demand and cost of prefabricated building components.

Therefore, the prefabricated building network has made a questionnaire for the current development of PC factory.

When the demand for production capacity is insufficient, they still need to pay fixed wages, which will bring a certain cost burden.

At present, they focus on promoting prefabricated buildings in the residential market, clarify the prefabricated assembly rate in the link of land transfer, and the incremental cost of prefabricated buildings can be roughly balanced in the cost of real estate development.

This paper briefly analyzes and summarizes the survey data.

In order to reduce the labor cost, some PC component factories choose to outsource labor services and organize the production of workers by signing labor contracts with labor companies.

Price of prefabricated components in terms of the price of prefabricated components, major cities across the country successively publish the reference information price of prefabricated components every month.

At present, China’s prefabricated buildings are not the spontaneous behavior of the market, but driven by the government.

The situation of “cherishing money” in the market is serious, the contradiction between supply and demand intensifies, and the sense of distrust increases.

At the same time, the cruel external market competition situation is also beginning to take shape.

(ID: yuzhijianzhuwang) with the continuous promotion of relevant national policies on prefabricated buildings, the application of concrete precast PC components is increasing day by day.

Steam curing conditions PC components need to meet certain strength requirements before demoulding, and the concrete strength shall not be less than 15MPa.

In terms of geographical location, the questionnaire results show that the unbalanced development layout of prefabrication factories in China is more prominent, mainly concentrated in the Yangtze River Delta, Pearl River Delta and other regions.

Product types at present, China’s prefabricated component products are mainly concentrated in prefabricated wallboards, prefabricated floors, prefabricated beams, prefabricated columns, prefabricated stairs, prefabricated balconies and so on.

The production of prefabricated components is an important part of prefabricated buildings, and its product quality directly affects the smooth implementation of prefabricated buildings.

Labor: labor outsourcing or self-employed mode: the price of Chinese labor workers is rising year by year, and the wage growth is also gradually accelerating.

Especially at the peak of payment collection at the end of the year, the game caused by the shortage of funds among all parties in the market has a growing trend.

Economically developed regions have made great efforts to transform and upgrade the construction industry and promote the modernization of the construction industry.

The price composition of prefabricated components includes direct costs such as materials, labor, equipment and facilities, as well as indirect costs such as management fees, profits and taxes.

In the third and fourth tier cities or economically underdeveloped regions, the proportion of prefabricated buildings is required to be small, and the local market space is small.

Therefore, the development layout of prefabrication factories in the country is uneven.

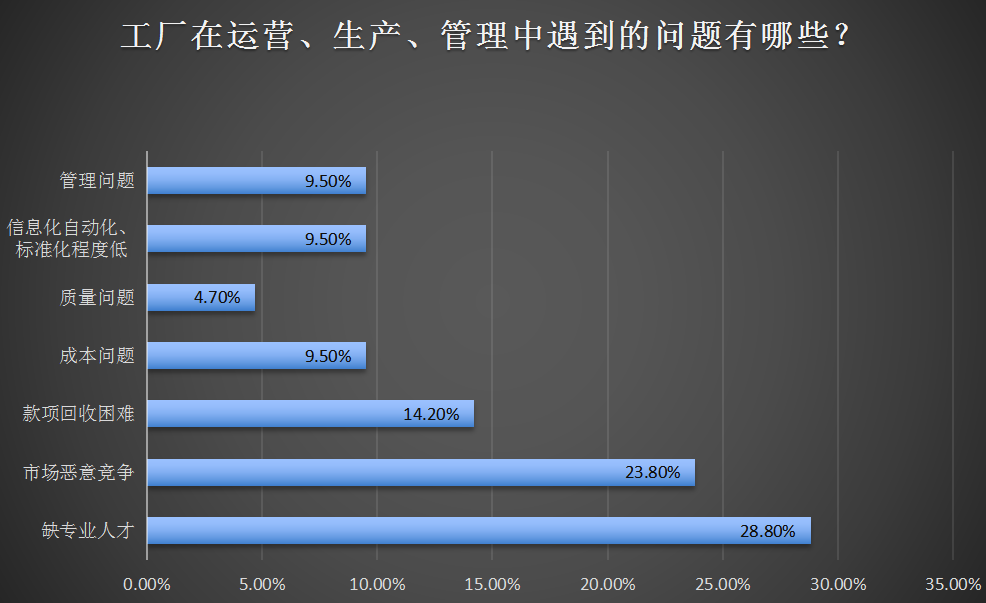

Problems encountered in the development of the company during the investigation, the problems generally reflected by enterprises are mainly concentrated in: talent pressure (28.8%), vicious market competition (23.8%) and fund recovery (14.2%)..

However, there are also some problems such as uneven quality of dispatched personnel and difficult management.

The traditional maintenance methods of PC components include natural maintenance, steam maintenance, solar energy maintenance, infrared maintenance, etc., of which natural maintenance (12.2%) and steam maintenance (87.8%) are common.

However, due to the industrial workers trained by themselves, the quality is relatively higher and the product quality is more guaranteed.

The policies of local governments are different.

2021 production and operation in 2021, affected by multiple factors, including abnormal fluctuations in bulk material prices, debt crisis of large real estate enterprises, regional shortage of energy (power) supply, normalization of novel coronavirus epidemic prevention and control, etc.

It has gradually become the main product of PC industry, and the development of municipal components has been relatively healthy and orderly.