1.

Preface during the appearance inspection of fire-resistant prefabricated parts, it is often found that there are many pores (mm or even cm) on the surface, as shown in Figure 1.

These pores, especially the larger pores, will not only affect the appearance, but also affect the service performance of the product.

Figure 1.

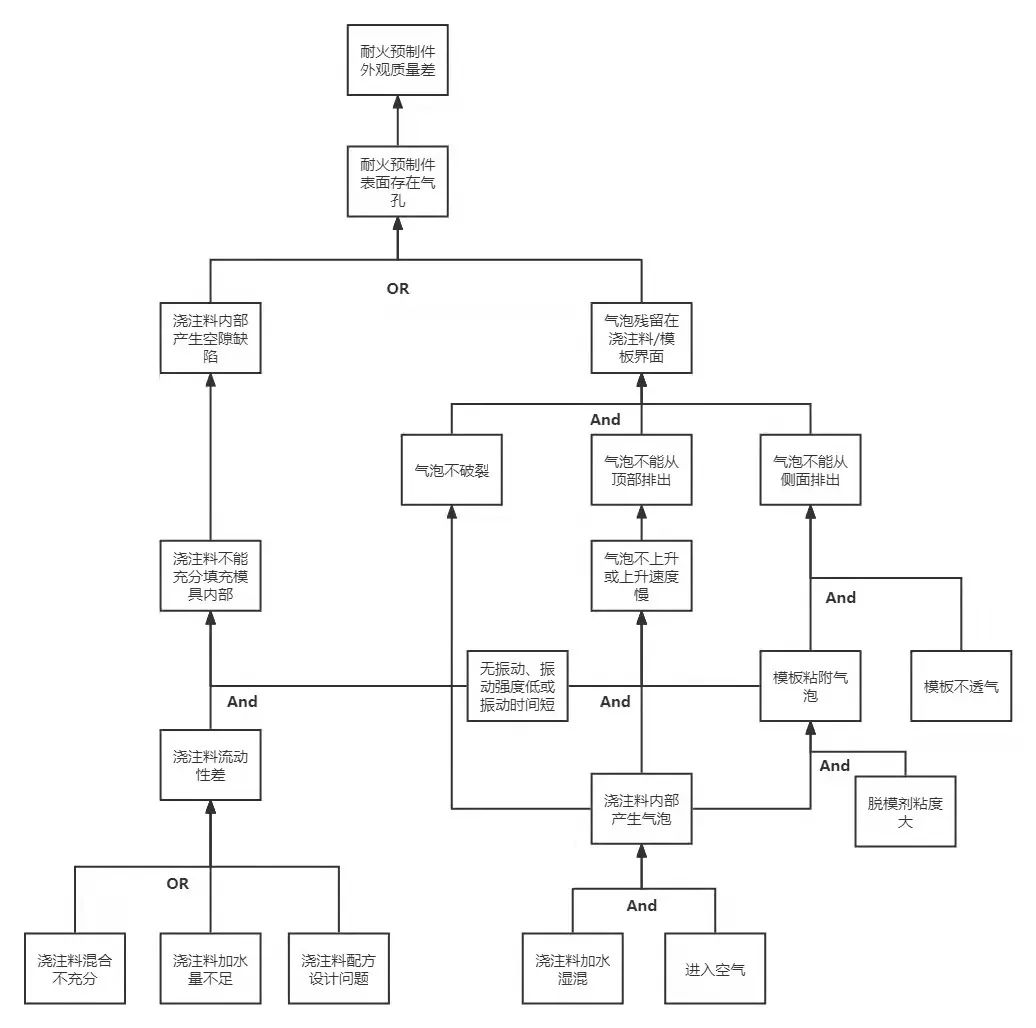

Surface of refractory preform 2 Causal chain analysis causal chain analysis can help us have a deeper understanding of the problem, get the deep causes of the problem, and find more breakthroughs to solve the problem.

The appearance defect of the preform is defined as the appearance defect of the preform (Note 2).

Fig.

2 causal chain analysis of (large) pores on the surface of refractory preform 3 After analyzing the causal chain and combining professional knowledge, it is considered that after the following key shortcomings and corresponding key problems are solved, the problem of (large) pores on the surface of fire-resistant prefabricated parts can be better solved, as shown in Table 1, and the problem solutions are listed at the same time.

Table 1 list of key shortcomings, key problems and solutions No.

key shortcomings key problems solutions 1 insufficient mixing of castables improve the mixing effect of castables, increase the mixing strength and prolong the mixing time 2 insufficient water addition of castables and increase the amount of water addition on the premise of ensuring no segregation and affecting the service performance, increase the amount of water to improve the fluidity 3 Optimization of castable formula design optimization of castable formula design optimization of castable particle gradation Optimization of dispersant to improve fluidity 4 how to enter the air without entering the air vacuum 5 how to improve the exhaust effect 5 how to discharge the bubbles from the top vibration parameter optimization, pressurized vibration molding and machine pressure molding 6 how to reduce the viscosity of release agent 7 how to make the bubbles burst defoaming technology is adopted.

There are many commonly used defoaming methods, which can be divided into physical defoaming method, mechanical defoaming method, chemical defoaming method and natural defoaming method according to the principle.

Such as defoamer, ultrasonic defoaming method, etc.

8.

How to make the formwork airtight? The micro nano pore template design is adopted, and the slurry cannot pass through, but the gas can pass through (negative pressure if necessary).

9.

There are pores on the surface of fire-resistant preform.

How to eliminate the pores and fill the pores with repair technology.

In the process of solving key problems, TRIZ innovative method can be used to get more solutions.

For example, for the key problem of how to improve the exhaust effect, the material field model in TRIZ innovative method is used for analysis.

This problem is an insufficient model, and the second and third level standard solutions of 76 standard solutions can be used.

For example, No.15 double field model can be formed by pressure vibration on the basis of (vibration) pouring; No.

16 uses a more controllable field, does not use (vibration) pouring, but uses machine press molding.

References: [1] Sun Yongwei, [US] Sergei ikvanke TRIZ: the golden key to open the door of innovation I Beijing: Science Press, 2015 [2] defoaming Baidu Encyclopedia (written by Cao Xiying)..