1.

foreword refractory prefabricated parts are products that the manufacturer casts or shapes the amorphous refractory materials into a certain shape for the convenience of direct masonry [1].

However, the fire-resistant prefabricated parts are prone to cracks in the production process, which will affect the service performance of the products, and even cause the products to be scrapped [2].

Similar problems also exist in the field construction of refractory castables [3].

Figure 1 is a schematic diagram of the cracking of the fire-resistant prefabricated parts.

Fig.

1 Schematic diagram of cracking of fire-resistant prefabricated parts 2 Analysis on the cracking causes of fire-resistant prefabricated parts [4] based on the leading field search [5], fire-resistant prefabricated parts and concrete components, or fire-resistant castables and concrete are similar in composition, structure and construction, so fire-resistant prefabricated parts (fire-resistant castables) can learn from the relevant research of concrete.

Generally, the cause of cracks in the production process of fire-resistant prefabricated parts is that the shrinkage is limited, resulting in tensile stress, which exceeds its own strength and cracks.

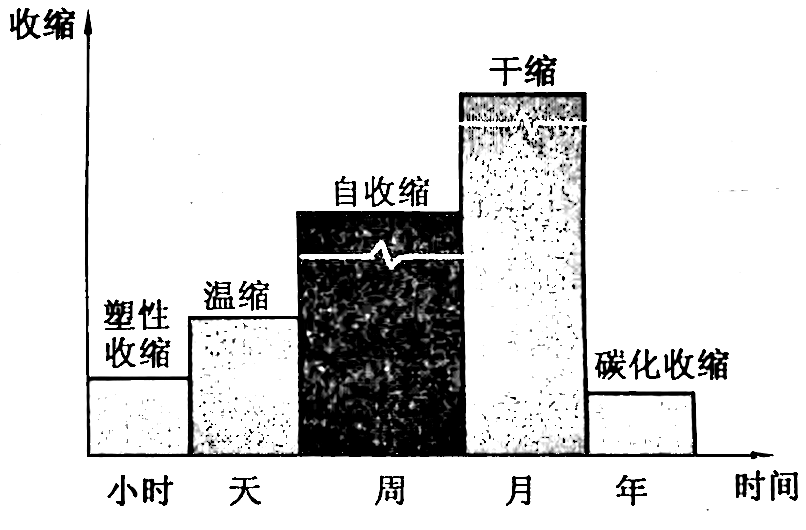

Based on the research of concrete, the shrinkage produced is mainly plastic shrinkage, temperature shrinkage, self shrinkage, dry shrinkage and carbonation shrinkage.

The approximate stage and amount of each shrinkage with the development of concrete age are shown in Figure 2.

Fig.

2 shrinkage time and amount of concrete at present, more and more attention has been paid to the cracking caused by the shrinkage of fire-resistant prefabricated parts, and some measures have been taken to improve it [2][3][6][7].

However, for large volume fire-resistant prefabricated parts, such as the prefabricated parts of electric furnace roof and blast furnace tapping ditch, the mass of a single piece can reach several tons, and the size can reach 2-3 meters or even longer.

During its preparation, it is very easy to have large or even penetrating cracks, resulting in the scrap of prefabricated parts.

The analysis shows that the cracking caused by temperature shrinkage is one of the important reasons.

It should be noted that the temperature deformation can be divided into two cases.

One is the temperature deformation of the hardened prefabricated parts, which is a structural design problem; The other is the temperature deformation during the hardening process of castables, which is considered in this paper.

Temperature deformation mainly refers to the expansion of castable after pouring with the heat release of cement hydration (or other reactions), and the contraction during the cooling process after the peak temperature.

The castable is still in the plastic stage during the temperature rise process, and the resulting expansion generally has little effect on the properties of the castable.

The temperature shrinkage, also known as cold shrinkage, actually refers to the volume shrinkage of the castable with the decrease of temperature.

Under the same temperature change conditions, the temperature deformation depends on the temperature deformation coefficient of the castable, that is, the linear shrinkage coefficient of the castable under the unit temperature change conditions (refer to concrete, usually (6-12)) × 10-6/ ℃).

The harm caused by mass precast units is more significant, because the hydration heat release of mass precast units is very large, and the heat dissipation is very slow (refer to the internal temperature rise of mass concrete as high as 60-90 ℃).

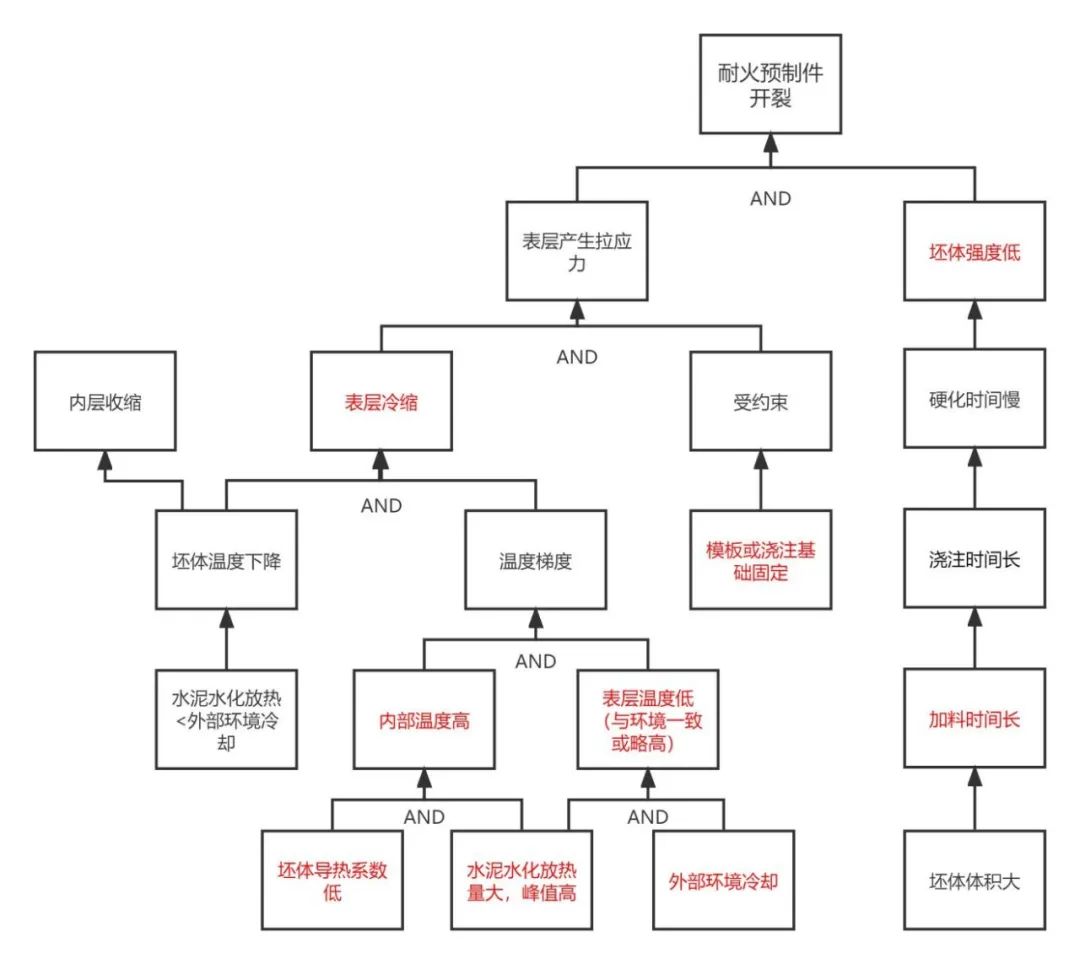

Figure 3 shows in detail the cause and effect chain analysis of the cracking caused by the temperature shrinkage of the fire-resistant preform.

The initial defect is defined as the cracking of the fire-resistant preform.

Causal chain analysis can help us have a more in-depth understanding of the problem, draw the deep causes of the problem, and find more breakthroughs to solve the problem [8].

Fig.

3 cause and effect chain analysis of cracking caused by temperature shrinkage of fire-resistant prefabricated parts note: red font is the key defect.

3.

(aluminate) cement hydration heat research because the temperature shrinkage of mass concrete is the main cause of cracking, the research on cement hydration heat is very important.

Gb/t12959-2008 method for determination of hydration heat of cement [9] specifies the principle, instruments and equipment, laboratory conditions, materials, test operations, calculation and treatment of results, etc.

of the method for determination of hydration heat of cement.

This standard is mainly applicable to Portland cement.

The determination methods include: dissolution heat method (Reference method) and direct method (alternative method).

Table 1 shows the heat release of different cement mineral compositions.

Table 1 heat release of different cement mineral compositions [4] mineral heat release, j/gc3s500c2s260c3a870c4af420 note: the unit of heat release in the original table is mj/kg, which is converted here.

In the determination method of cement hydration heat, the direct method is to directly measure the temperature change of cement mortar (due to cement hydration) in the calorimeter under a constant temperature environment, and calculate the sum of accumulated and lost heat in the calorimeter to obtain the hydration heat within 7 days of cement hydration.

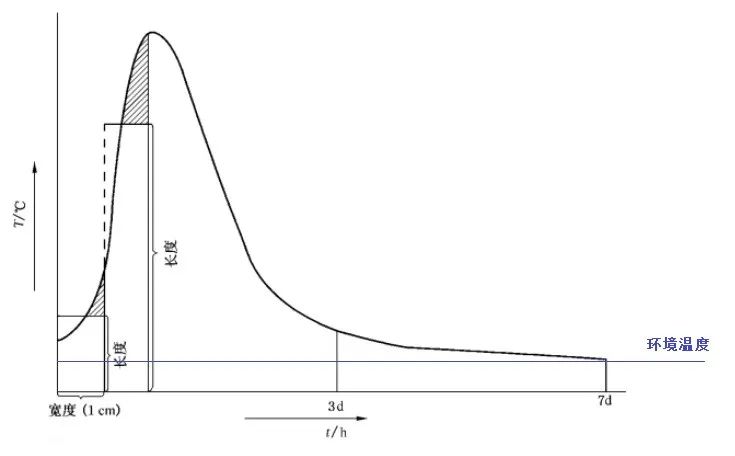

Figure 4 shows the measured cement mortar temperature curve.

When the cement mortar temperature reaches the ambient temperature, the product of the area surrounded by the curve and the straight line of the ambient temperature and the heat dissipation constant of the calorimeter is the hydration heat in this period.

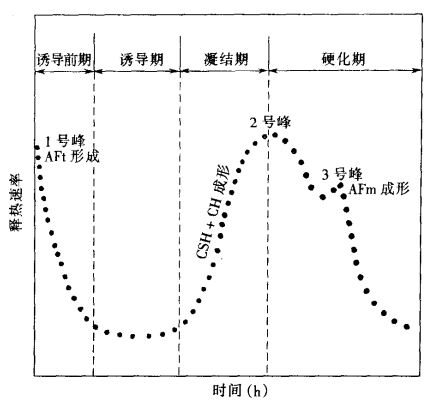

Figure 4 the temperature curve of cement mortar is derived from the curve in Figure 4 to obtain the curve of hydration and heat release rate of cement (mortar), as shown in Figure 5.

From the heat release rate, the hydration process can be divided into four stages [10]: early induction stage, induction stage, condensation stage and hardening stage.

(Note: there are also five stages [11]: initial period, induction period, acceleration period, deceleration period and stability period) Figure 5 diagram of hydration heat release rate curve of cement (mortar) 4 The total hydration heat of aluminate cement is 450-500j/g, which is similar to that of Portland cement.

The hydration heat of aluminate cement will release 70%-90% within 24h (20 ℃), while that of Portland cement will release only 25%-50% within 24h [12].

Referring to the research method of hydration heat of (Portland) cement, the hydration heat of aluminate cement commonly used in refractory castables has also been studied [13][14][15][16], such as aluminate cement with different types, particle sizes and impurity components, curing temperature and methods, adding different types of alumina powder and additives, etc.

However, the main concern of the research is the hydration behavior of aluminate cement, which aims to regulate the setting and hardening process of aluminate cement..