1.

Prepare the construction site inside and outside the site, make good preparations for “three supplies and one leveling” roads, water, electricity and the whole site, and set up the site temporary facilities and the storage yard of PC structure; In order to meet the construction requirements of PC structure construction and the maximum weight of single component of PC structure, ensure that the lifting distance of PC structure of each house is met, and according to the construction progress and the site layout requirements, 4 stc7015 tower cranes are equipped for buildings 1 # ~ 4 # of the project, which are reasonably arranged near each house to ensure that the nodes on the floor are lifted every 5-6 days on average.

2.

The off-site PC prefabricated components shall be manufactured in a factory and professional prefabricated component production units shall be selected; After the prefabricated components are processed in the factory, they are transported to the construction site for hoisting and installation by the general contractor.

Transportation: in order to ensure that the PC structure can enter the construction site and be transported smoothly on the construction site, the main gate road shall be set at least 8m wide, and the road on the construction site shall be set at 5m wide, so as to ensure that the PC structure transport vehicles can pass in both directions on the main gate road, and ensure the smoothness of turning and straight walking on the construction site.

3.

When transporting prefabricated components, the vehicle shall be started slowly and the speed shall be uniform.

When turning and changing lanes, the vehicle shall be slowed down to prevent the wallboard from overturning.

The PC structure of the project is characterized by a large number of single layers and a large weight.

The drawing shows that the PC structure of each room is about 4m long and weighs about 4.6t.

According to the above construction requirements and the convenience of PC structure hoisting construction, the PC structure management team plans to set up a PC storage yard for each room.

The storage yard is the basement roof (with fire lanes and reinforcement measures at the bottom).

The rest of the construction roads around the basement are cast with 200 thick C20 concrete, of which the main road on the non basement and the PC storage yard must be laid Φ 18@150 Single layer two-way reinforcement.

The rebar transport vehicle and PC storage yard must use the basement shift as the construction road and material storage yard.

According to the requirements and the actual situation, the basement roof within the scope of the vehicle road and PC storage yard shall be reinforced.

In particular, the vehicle line shall be reinforced with steel pipes.

All bent steel pipes shall be removed after the structure is capped.

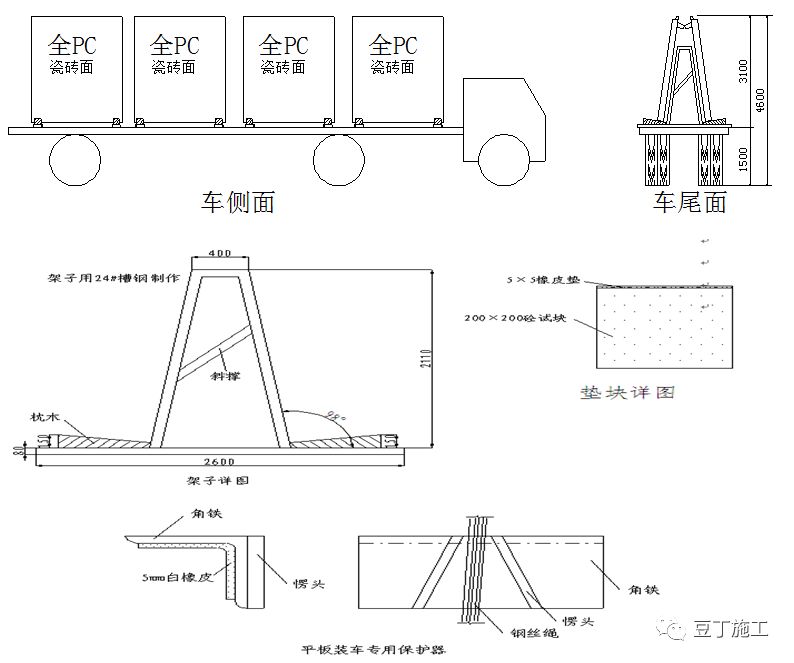

The wallboard shall be placed vertically, and the supports meeting the rigidity requirements shall be made of channel steel.

The supporting points of wallboard shall be set at both ends of the bottom of wallboard, and the stacking site shall be flat and solid.

Flexible materials can be used for supporting points.

After stacking, temporary fixing shall be adopted.

Temporary enclosure measures shall be taken for the site.

Due to man-made collision or tower crane mechanical collision and dumping, the PCs in the storage yard form a domino collapse.

The storage yard is stacked in a staggered and orderly manner according to the lifting sequence, with a certain interval between plates.

As shown in the following figure, the finished product protection measures must be taken during the transportation, stacking and hoisting of the PC structure of the project.

Steel frame is used for auxiliary transportation during transportation.

When transporting wallboard, the car starts slowly and the speed should be uniform.

When turning and changing lanes, it should be slowed down to prevent the wallboard from overturning.

Due to the heavy construction of PC in this project, it is difficult to protect the storage yard and transport finished products.

Cotton yarn or rubber blocks are used at the junction of PC structure and steel frame to ensure that the PC structure and steel frame are damaged due to collision during transportation.

In the process of stacking, steel carrying poles shall be used to keep the PC structure balanced, stable and light during the lifting process.

Cotton yarn or rubber blocks or sleepers shall also be placed at the stacking position of the PC structure before light lifting, so as to keep the lower part of the PC structure flexible; Stairs, balconies and other PC structures must be stacked in a single piece.

When stacking, four wooden blocks of uniform size shall be used for padding.

The height of the wooden blocks must be greater than the height of the exposed stirrups and edges of the laminated plate to avoid damage to the PC structure.

At the same time, cotton yarn or rubber blocks shall be properly placed on the padding to keep the lower part of the PC structure as a flexible structure.

In the process of hoisting construction, attention should be paid to the method of finished product protection.

On the premise of ensuring safety, the PC structure should be lifted and placed gently.

At the same time, before installation, the plastic gasket should be placed at the position of fine adjustment of the PC structure.

The plastic gasket is a flexible structure, which can effectively reduce the damage of the PC structure.

During construction, PC structures such as stairs and balconies shall be covered and protected with wooden boards.

Before pouring, the sleeve connecting and anchoring rebar shall be protected by finished PVC pipe to prevent contamination of the connecting rebar during concrete pouring and tamping, which will affect the later PC hoisting construction.

3.

On site construction of PC structure 4.

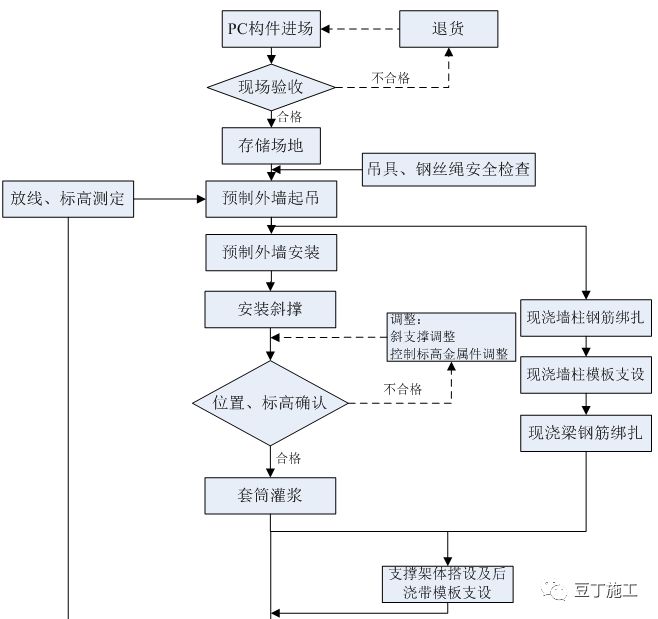

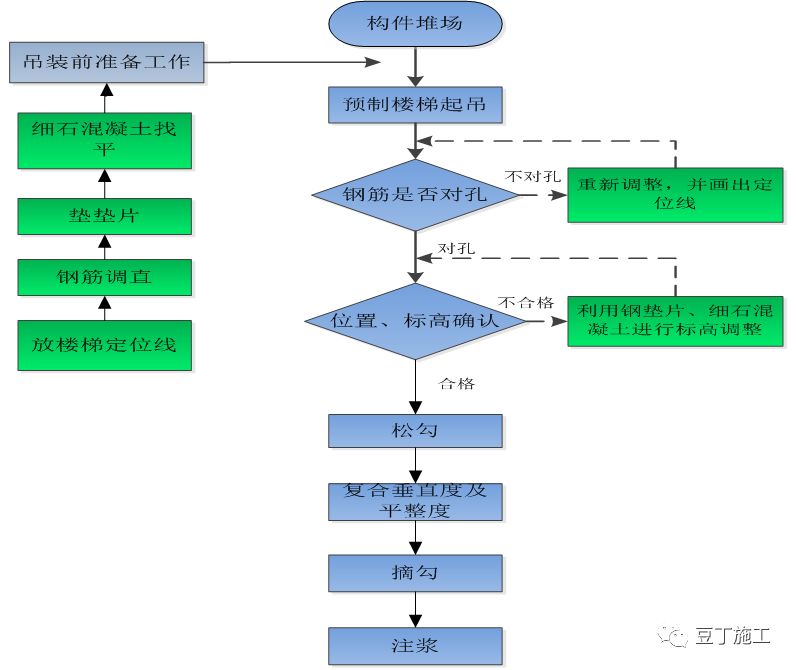

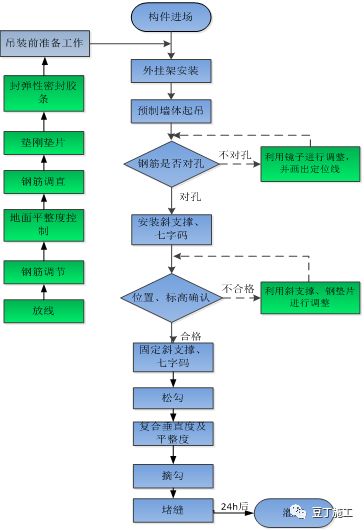

Lifting scheme of prefabricated components 4.2.1 lifting process of prefabricated wall 4.2.2 preparation before lifting of prefabricated external wall 4.2.3 before lifting of prefabricated external wall, the quality director shall check the model and size of the wall panel, and after the quality is checked, a special person shall be responsible for hooking.

When the hooking personnel evacuate to the safe area, the signal workers below shall confirm the safety conditions around the components, and conduct trial lifting after confirmation, and command the slow lifting, When the crane is lifted to about 0.5m from the ground, the tower crane shall continue to lift after the lifting device is determined to be safe.

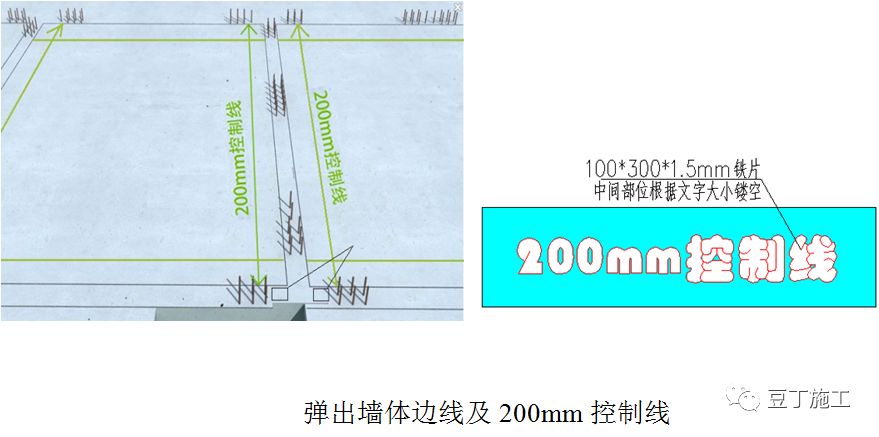

When the wall is lowered to 0.5m from the floor, fine tune it according to the pre positioned guide frame and control line.

After fine tuning, slow down the lowering.

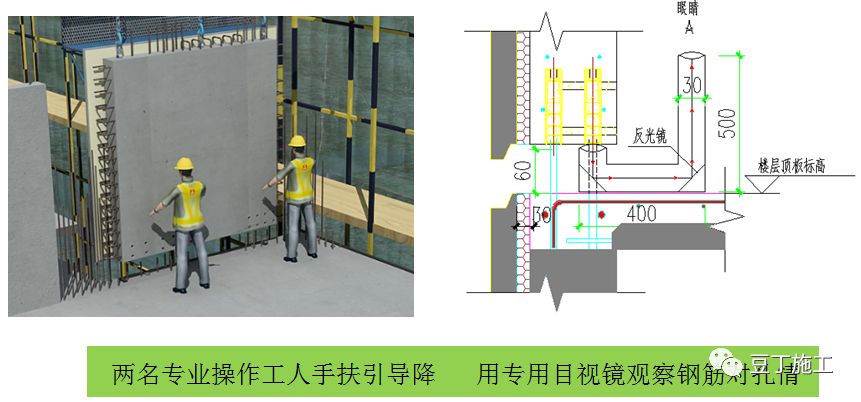

Two professional operators shall guide the landing with their hands.

When the landing reaches 100mm, one worker shall observe whether the connecting rebar is aligned with the hole with a special visual glass.

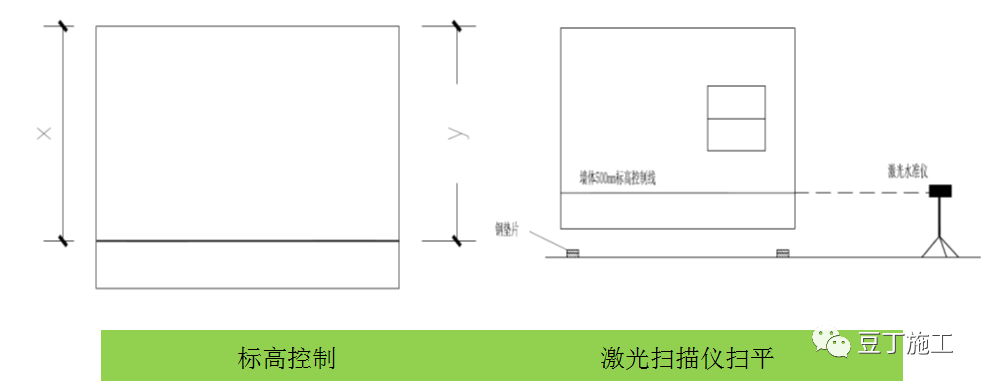

4.2.5 installation of prefabricated external wall (the hoisting personnel on the working face shall adjust the position of components according to the position line, elevation control line and embedded reinforcement in advance, prepare the sizing block, place the components in the control line, and place the sizing block) method 2: record the elevation a value and the average elevation b value of each point clearly, and after the corresponding prefabricated external wall enters the site, the internal leaf wall height C value of the corresponding gasket position can be obtained after passing the acceptance, Then, the height value D of the spacer can be obtained by the equation calculation according to the floor height of 2900mm..