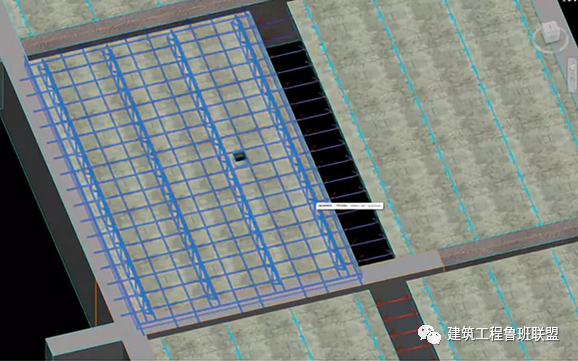

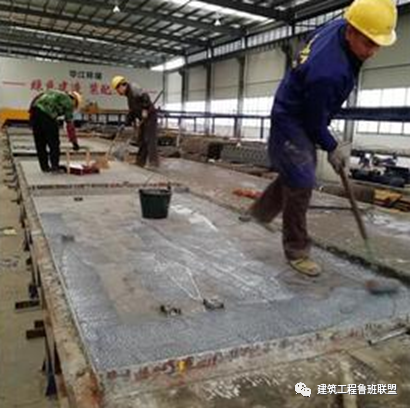

The composite member is composed of prefabricated concrete member and post cast concrete, and is a whole stressed structural member formed in two stages; Laminated floor is the most commonly used prefabricated horizontal component in prefabricated buildings.

The prefabricated layer of the laminated plate can be used as the permanent formwork of the upper cast-in-situ laminated layer, and the horizontal equipment pipeline can also be laid in the cast-in-situ layer.

The mechanical and electrical systems of equipment in different functional buildings are quite different.

Therefore, the openings and reserved embedments that need to be reserved and embedded on the prefabricated plate of the laminated plate are also different.

Whether the pipeline is exposed or concealed, it will be more or less reserved and embedded on the laminated plate.

The accuracy of the detailed design of the reserved and embedded on the laminated plate will have a direct impact on the processing and production of prefabricated components and the construction and installation at the construction stage.

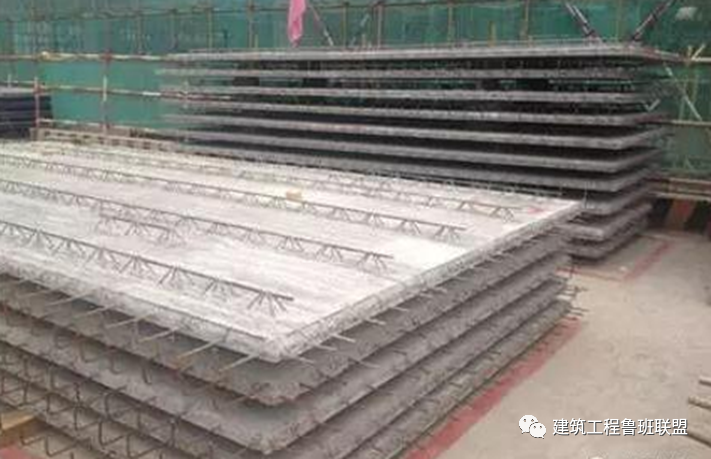

The commonly used composite plate is the truss reinforced concrete composite plate (60mm thick bottom plate).

The special structure of the truss reinforcement will also have a great impact on the reserved opening and the embedding of the wire box.

Combined with the detailed design of prefabricated building laminated floor and the practice of prefabricated building installation engineering, this paper mainly analyzes the existing common problems of the detailed design of the laminated floor and the later construction problems, and puts forward the optimization measures for revising the construction drawing design and the cooperation between the disciplines at the stage of the detailed design, so as to ultimately improve the efficiency and quality of the detailed design of prefabricated building components, So as to reduce the adverse impact on the processing and production of prefabricated components and the assembly construction of components.

Common mechanical and electrical reserved and embedded problems in the detailed design of laminated slab background: the laminated floor is a relatively simple component in the construction and implementation of prefabricated buildings.

However, in the actual engineering practice, due to the inadequate coordination between disciplines at the construction drawing stage and the insufficient precision of the detailed design, the reserved and embedded on the laminated floor is missing or inaccurate, resulting in a lot of rework for component processing and construction and installation, Thus greatly affecting the construction period and causing large economic losses.

The following lists the common reserved and embedded problems on the composite plate in combination with specific projects: 1) the design height of truss reinforcement is wrong, and the concealed wiring pipe on the composite cast-in-situ layer cannot pass through the truss reinforcement, which causes the on-site construction to remove the groove on the prefabricated plate or increase the support to cancel the chord on the local truss reinforcement; 2) There are many and concentrated local pipelines in the superimposed cast-in-place layer, and the concentrated and large-diameter pipelines cannot pass through the truss reinforcement, resulting in the removal of truss reinforcement and prefabricated plate in the concentrated local part of the pipeline in the field construction; 3) The embedded electromechanical junction box is missing.

When there are many electromechanical systems or there are special needs, small system points are often missed in the detailed design, resulting in the installation of junction boxes at the site construction opening; 4) The distance deviation between the embedded position of the electromechanical junction box and the design point is large, which causes the deviation between the decoration and installation points and the design requirements to be too large, resulting in the need for re opening and installation of the junction box in the field construction; 5) The influence of truss reinforcement is not considered in the embedding and incoming direction of electromechanical junction box.

The embedded position of the junction box is close to the truss reinforcement, and the incoming direction collides with the truss reinforcement, resulting in the re opening of the junction box and no locking nut when the incoming direction is adjusted on site; 6) The electromechanical junction box is embedded close to the edge of the prefabricated plate, and the junction box is damaged during hoisting and transportation.

The damaged junction box needs to be removed and reinstalled on site; 7) The reserved holes for the downward vertical threading pipes of the electromechanical equipment are missing, resulting in the need to drill holes for the laminated prefabricated plates in the field construction; 8) The fire fighting and water supply and drainage floors are vertically through the pipes, and the reserved openings of the composite prefabricated slabs are missing, resulting in the need to cut the composite prefabricated slabs and re open the holes on site; 9) The fire-fighting and water supply and drainage floors are vertically through pipes, and the reserved opening positions and sizes of the laminated prefabricated slabs are wrong, resulting in the failure of penetration and installation of the upper and lower risers on the floors.

The on-site construction requires opening, cutting and reaming of the laminated prefabricated slabs; 10) The embedded casing on the prefabricated slab of the laminated floor is damaged during hoisting and transportation, and the casing reserved higher than the prefabricated slab surface is easily damaged, resulting in the need to remove the damaged casing and reinstall it in the field construction; The problems will not be described in detail.

The above reserved and embedded errors will cause the construction site to re process and correct the laminated prefabricated slabs.

The poor site accuracy and rough post-treatment will continue to cause a series of quality problems, such as slurry leakage and poor molding quality caused by the rear slotting of the junction box and the non dense interface after installation.

There are many reasons for many common problems, but it can also be seen from this that the splitting and deepening design of the single laminated plate run through the integrated design and the construction of the whole project.

Therefore, it is necessary to sort out and unify the professional cooperation of the prefabricated content design and the detailed design of the construction drawing design.

Common types of mechanical and electrical reservation and embedment of composite floor slab in view of the above-mentioned various deepening design problems, it is necessary to classify and summarize the common types of mechanical and electrical reservation and embedment on the prefabricated slab of composite floor slab, so as to facilitate the confirmation of mechanical and electrical reservation and embedment at the early stage of deepening design and avoid missing items.

It is also necessary for the deepening designer of structure discipline to fully understand these systems.

1) Electrical reservation and embedment of laminated floor (1) lighting system: the concealed light box of lighting system line pipe is placed at the bottom of the board.

The light box of lighting system is a common reserved and embedded component in residential and commercial buildings.

For residential projects with the demand of hardbound, the embedded light box must be accurately reserved at the lighting point at the bottom of the non ceiling plate, and the junction box of the non ceiling spotlight in the hardbound room must be precisely reserved in the laminated plate area.

(2) Fire protection system: it is required to reserve the embedded junction box at the bottom of the laminated prefabricated plate for the concealed laying of the fire protection system pipeline.

The reserved and embedded junction boxes of the fire protection system generally include: emergency lighting, evacuation indicator lighting, smoke detector in the automatic fire alarm system and fire emergency broadcasting.

(3) Strong current system: the control switch of the strong current system is set on the wall, and the circular threading hole shall be reserved in the area of the laminated plate.

When the pipe is laid in the cast-in-place layer of the laminated plate and needs to be laid down in the partition wall, the circular threading hole shall be reserved in the laminated prefabricated plate..