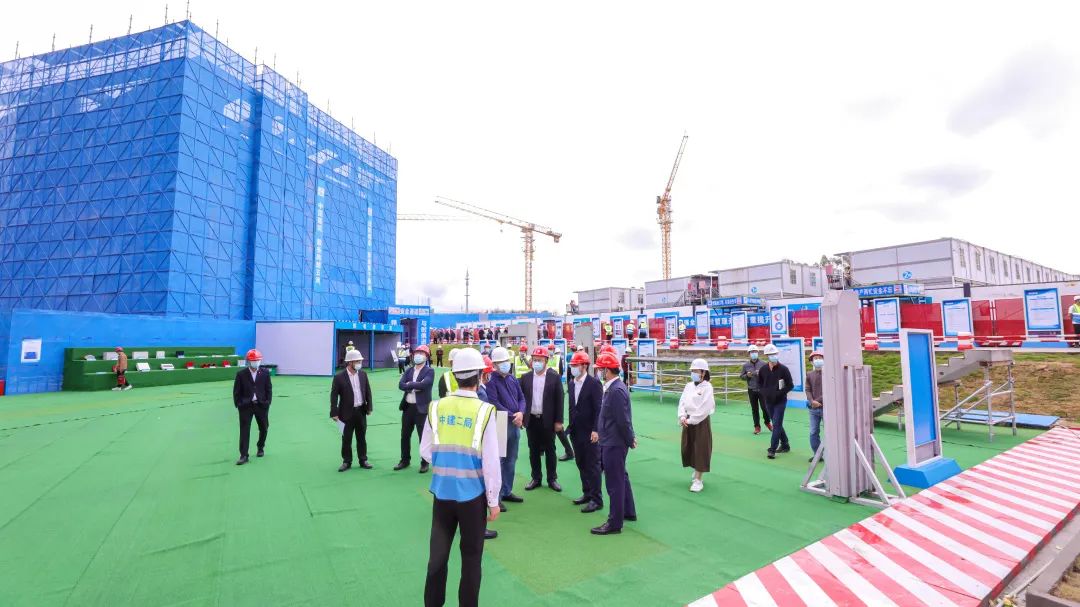

On November 22, the 2021 on-site observation activity of precast buildings hosted by the first company of the Second Bureau of construction in Guangming District of Shenzhen was held in the affordable housing and industrial supporting dormitory project of the inner garment base in shutianpu community.

The people of No.

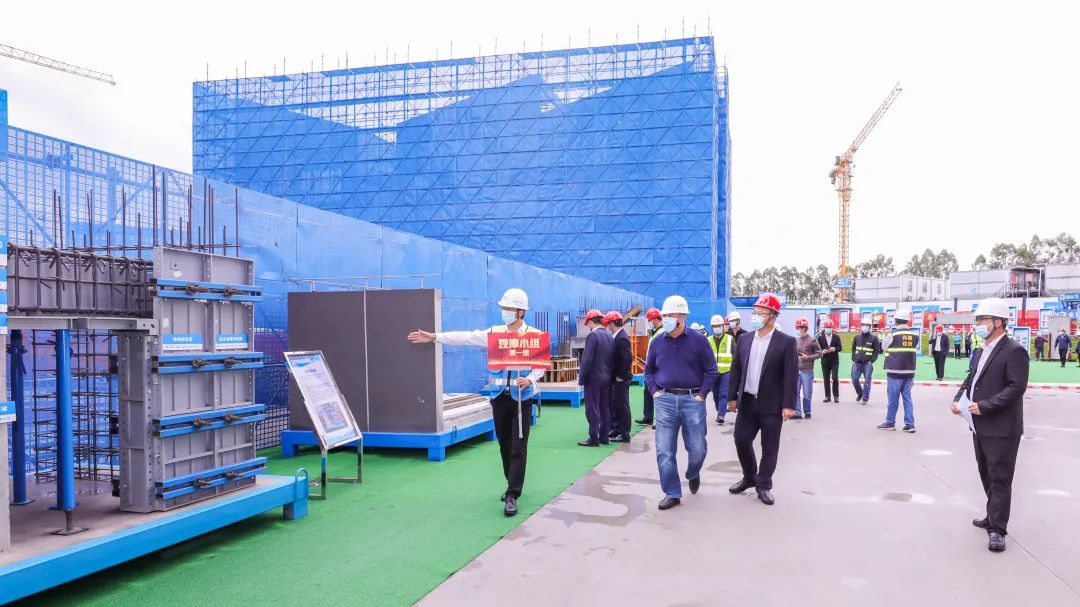

The observation meeting comprehensively demonstrated the technical highlights of the project’s cast construction.

▼ pay attention to the civil forum and immediately receive the information package from the South China branch of the first company of the Second Bureau of construction in Shenzhen.

Project overview the project is a key livelihood project of talent Anju group to implement the construction task of Anju project during the 14th Five Year Plan period.

1 company have been helping high-quality construction on the road and have made some achievements in the process of struggle.

More on-site observation pictures slide left and right to view the industrial supporting dormitory project of affordable housing and underwear base in shutianpu community, including 8 super high-rise towers, 2 multi-storey kindergartens, 1-2 floors of public supporting podium and 2-3 floors of basement.

First, let’s take a look at this technology.

The on-site observation meeting was held by nearly 300 experts from the whole city Colleagues in the industry share this exchange feast.

It is also an EPC project undertaken by our company as the leader of the consortium.

After completion, it will provide 4227 sets of affordable housing for the society.

The on-site installation of the section steel angle code is completed, the I-steel positioning reinforcement is welded, and the on-site example drawing is completed The coupling beam formwork support system is installed and slides left and right.

The phased achievement display project has completed the construction technology and many achievements such as the full turnover formwork support system of the connecting beam of the super high-rise daylighting shaft.

01 the “prefabrication five steps” of the project’s cast management and control: installation of precast external walls, click to learn and enter the site for acceptance → positioning and setting out → installation of elevation adjusting parts → lifting and installation of external walls → accurate positioning and diagonal brace installation → binding and connection of reinforcement → caulking Gluing Trilogy: installation of precast stairs, click to learn mobilization acceptance → positioning and setting out → steel gasket and mortar leveling → lifting and installation → accurate positioning → grouting and blocking Trilogy: installation of precast bay window, click to learn mobilization acceptance → positioning and setting out → installation of elevation adjusting parts → lifting and installation of bay window → accurate positioning and diagonal brace installation → reinforcement binding and connection and other follow-up work Trilogy: prefabrication Wall panel installation Click to learn positioning and setting out → brush adhesive → internal wall strip installation → verticality and flatness inspection → clamp installation → mortar caulking → pipeline positioning and slotting five steps: Precast laminated plate installation Click to learn positioning and setting out → support frame erection → laminated plate mobilization → laminated plate hoisting → floor reinforcement binding and pouring 02 how is the fine management done? The project continues to tackle key problems in lean construction technology, leading the project to improve work efficiency and quality through design, scheme optimization and new technology application; The excellent construction technology and technical achievements shall be summarized and popularized in time to speed up the transformation of achievements and provide high-quality technical services for “lean construction”.