Shaoxing, an ancient city, is full of beautiful mountains and rivers.

Shaoxing, located in the Yangtze River Economic Belt on the coast of the East China Sea, is famous both at home and abroad for its rich ancient Yue culture.

Now, the ancient cultural city has changed its appearance.

Hangzhou Shaoxing Taizhou Expressway, which is the longest mileage and the largest single investment expressway in the “12th Five Year Plan” of highway transportation in Zhejiang Province, is located here, marking a beautiful fast lane for Shaoxing to run out of the “acceleration” of development.

Recently, the reporter walked into the construction site of Pingshui Tunnel of the third contract section of Hangzhou Shaoxing Taizhou Expressway (hereinafter referred to as “the third contract section of Hangzhou Shaoxing Taizhou Expressway”) contracted by Zhejiang Jiaogong Group Co., Ltd.

In the tunnel, the sound of the machine is rumbling.

An intelligent rock drill with a pair of huge “arms” is drilling in the face of the tunnel.

When the drill is lifted and lowered, two round holes of the same size and depth appear in front of us soon.

The high level of tunnel construction mechanization is amazing.

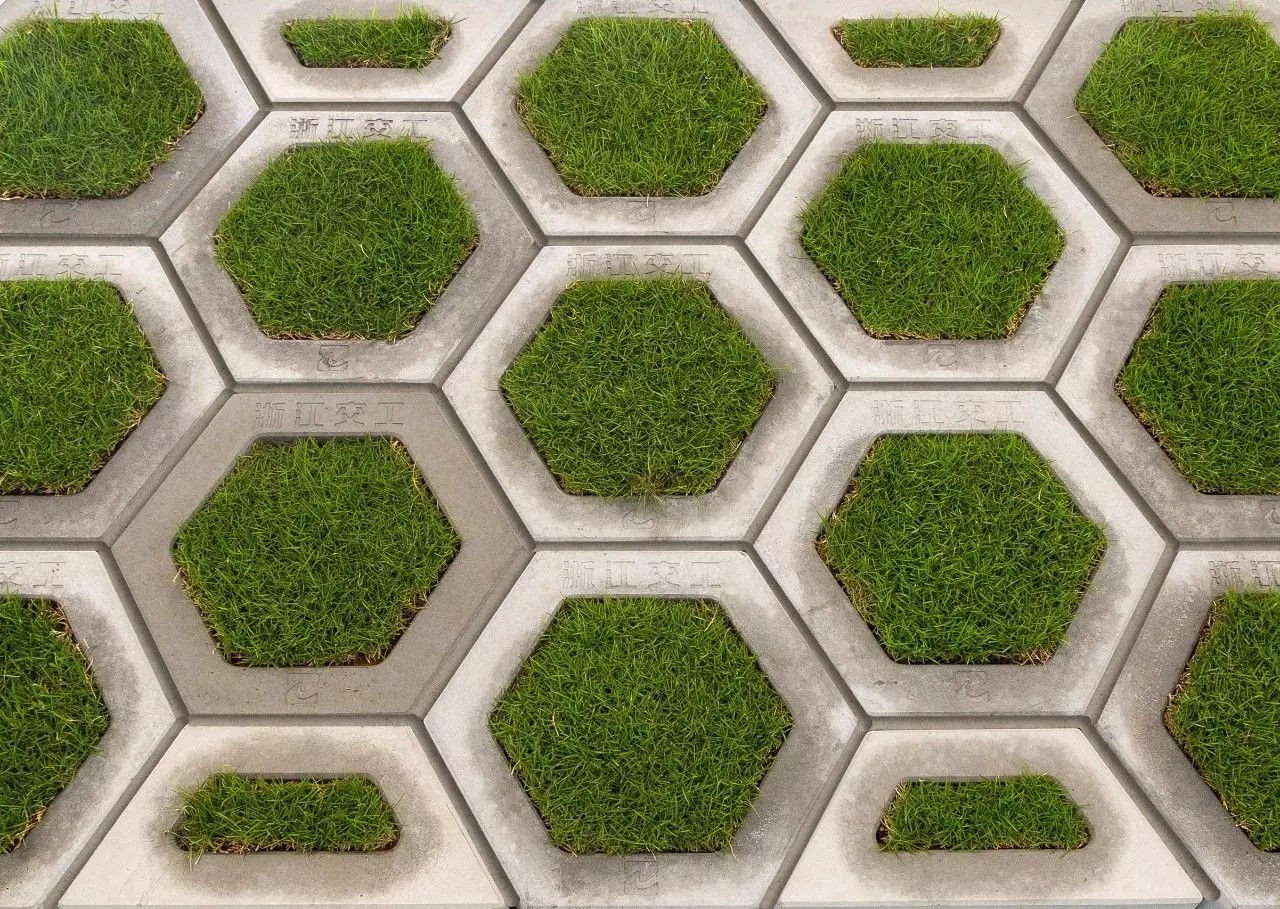

At the same time, in the processing area of the small component prefabrication center, the workers are methodically producing tunnel hexagonal blocks and cable trench cover plates on the assembly line.

On one side of the line are neatly stacked batches of exquisite finished products.

At a glance, it makes people think that they have mistakenly entered the boutique warehouse of a large supermarket.

The construction of delicate small components is famous.

Tunnel safety education.

In 2016, the Ministry of Transport issued the Guiding Opinions on Building the Quality Project of Highway and Waterway Transport, which clearly put forward the concept of building a “quality project”.

The construction goal of highway and water transport projects should be high quality, durable, safe and comfortable, economic and environmental protection, and social recognition.

From January 2017, a three-year demonstration of highway and water transport quality projects should be carried out.

The Department of Transport of Zhejiang Province took the lead in the country in July 2016 by issuing the Guiding Opinions on Carrying out the “Quality Project” Construction Activities of Highway and Waterway Transport in Zhejiang Province.

The construction of comprehensive transport infrastructure is in full swing, and the practice of comprehensively improving the quality of transport projects is getting deeper and deeper.

On August 21, 2017, the Zhejiang Provincial Highway and Waterway Transportation Quality Project Promotion Conference and the Site Conference on Standardization of Highway Tunnel Construction was grandly opened in the Hangzhou, Shaoxing and Taizhou Contract Section III Project Base.

Zhejiang Transportation Engineering Co., Ltd., as the contractor of this section, was responsible for the specific preparation of this site conference.

It is reported that the third contract section of Hangzhou Shaoxing Taizhou Expressway is the first bid section of Shaoxing Jinhua section of Hangzhou Shaoxing Taizhou Expressway, which starts from Dayao Mountain and ends at Pingshui Tunnel.

The main line is 7.06 kilometers long, involving a Jianhu interchange, 31 bridges and 2.5 tunnels with a total length of 3.49 kilometers.

1.

The concept first builds a “model” for tunnel construction standardization, “seven mountains, one water and two fields”.

Zhejiang Province has a complex terrain, with mountains and hills accounting for more than 70% of the province’s area.

Therefore, tunnel projects account for a high proportion in the construction of expressways and national and provincial highways in the province.

The total length of Hangzhou Shaoxing Taizhou Expressway is about 162 kilometers, including 115 kilometers of Shaoxing Jinhua Section.

The ratio of highway bridges to tunnels is as high as 80%, which puts forward higher requirements on the difficulty of tunnel construction.

The dobby rock drill enables accurate drilling.

At the beginning of the project construction, the third contract section of Hangzhou, Shaoxing and Taizhou put forward the construction goal of “creating provincial excellence and striving for national excellence”, and actively formulated a set of project management plans throughout the whole process of project construction based on the relevant requirements of the Ministry of Transport and the Provincial Department of Transport for the creation of “quality projects”.

The “three modernizations” concept of “standardization, refinement and informatization” is the construction guide throughout, leading the “three innovations” of “concept innovation, management innovation and technology innovation”.

In this context, the third contract section of Hangzhou, Shaoxing and Taizhou was “customized” for the first time in tunnel construction.

It introduced and independently developed “Jiutaitao Tunnel Series Construction Equipment”, which was fully applied to the whole process of tunnel construction, triggered a “revolution” in tunnel construction, and forged a “model” for tunnel construction standardization in Zhejiang Province.

“In the past, only a few sets of simple equipment were used sporadically during tunnel construction, and it was the first time that mechanized equipment was used in the whole process of highway tunnel construction in the whole province and even in the whole country.

The terrain of the project area is complex and there are multiple fault zones, so the construction technology is difficult.

The project department, combining the actual situation of the project, has greatly reduced the tunnel construction safety risk and improved the project quality through the combination of purchasing and independent innovation research and development equipment Add more guarantees.

” The technical director of the third contract section of Hangzhou, Shaoxing and Taiwan told reporters that, “There are nine sets of tunnel construction equipment, namely, two machines, one bridge and six cars.

The second machine is a multi arm rock drill and wet spraying manipulator, the first bridge is a self-propelled mobile trestle, and the six cars are respectively a multi-functional arch frame trolley, a second lining thickness pre inspection trolley, a multi-functional waterproof operation trolley, a new type of second lining trolley, a second lining maintenance trolley, and a cable trench trolley.” The new type of second lining trolley improves the common quality problems such as the second lining stagger.

“This is the dobby rock drill.” Following the direction pointed out by Li Kaibo, a technician at the construction site, the reporter saw this “Transformers” that can be used from left to right.

It is understood that this is the first dobby rock drill used in the construction of highway tunnels in Zhejiang Province, which has achieved all-round precision drilling, sharply reducing the number of people drilling in the face from 18 to 3, improving the safety factor and construction efficiency, and at the same time increasing the qualification rate of anchor rod drilling angle to 100%..