According to the editor, since 2018, the country officially issued the Evaluation Standard for Fabricated Buildings [GB/T51129-2017], marking that China’s prefabricated building industry has really entered a substantive stage.

With the popularization of prefabricated buildings, the amount of precast concrete components has increased rapidly.

According to incomplete statistics, the number of precast concrete plants in China increased explosively in 2018, with about 300 PC plants and more than 500 PC production lines added throughout the year.

In 2019, the number of precast concrete production enterprises in China grew rapidly.

According to incomplete statistics, nearly 200 new precast plants were added in this year, and by the beginning of 2020, there had been more than 1000 precast plants with a scale of more than 30000 cubic meters nationwide.

More than 600 prefabrication plants have been built in the past three years.

The assembly industry is rapidly developing from the initial stage to the cultivation stage, and the leading role of key regions is gradually highlighted.

PC factory project construction is also gradually changing from irrational resources to professional and refined investment.

In order to make full use of the omni-directional, three-dimensional and multi-channel communication advantages of the media, aggregate high-quality resources and establish the industry brand image, the prefabricated construction network started the activity of “looking for an excellent reputation component factory” on April 21.

Since the opening of the event, the platform has received nearly 100 enterprises to register for participation.

I would like to thank all enterprises for their active participation, which has made our event go smoothly.

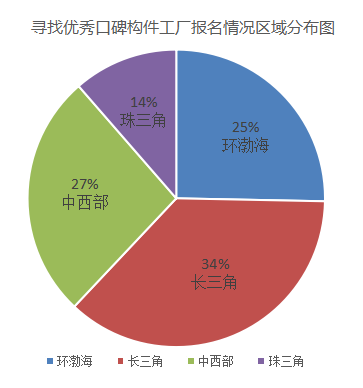

Now, according to the registration received so far, the following regional statistical chart is made: when the activity enters the network exhibition stage, we will push and publicize some component factories by stages.

Publicity in this issue: Zhejiang Baoye Modern Building Industrialization Manufacturing Co., Ltd.

Longxin Group Jiangsu Construction Industry Co., Ltd.

Jiangsu Yuhui Residential Industry Co., Ltd.

Nanjing Tiangu Building Technology Co., Ltd.

Nanjing Dadi Construction Technology Co., Ltd.

Suzhou Ruizhitong Building Technology Co., Ltd.

China Coal Yuanda Huaibei Building Industrialization Co., Ltd.

Zhejiang Baoye Modern Building Industrialization Manufacturing Co., Ltd Zhejiang Baoye Modern Building Industrialized Manufacturing Co., Ltd.

was jointly invested by Baoye Group and Siweide Group in 2013.

Specializing in the production, sales, development, research, installation and construction of new concrete prefabricated parts and related services and consulting; Sales of prefabricated housing models; Design consulting, construction consulting and technical services for prefabricated building projects; Construction project planning, design consulting and other businesses.

The company has introduced a full set of professional technology and equipment from Germany, has a fully automatic prefabricated component production line and intelligent deepening design software imported from Germany, and adheres to the professional quality of Germany to provide a more complete series of products for the Chinese market.

It has won many titles, such as the demonstration enterprise of integration of industrialization and industrialization in Zhejiang Province, the small and medium-sized enterprise company of science and technology in Zhejiang Province, and passed ISO9001, ISO14001, ISO18001, safety production standardization and other certifications.

At present, the site equipment has a fully automatic production line of concrete prefabricated components imported from Germany (the first imported automatic production line of concrete prefabricated components in Zhejiang Province), which can produce 400000 square meters of laminated plates annually.

One is the production line of fixed formwork prestress, which can produce 30000 cubic meters of solid wallboard and other special-shaped components annually.

The total area of the workshop and storage yard is 150 mu.

← Sliding left and right to view site equipment → Product service ← Sliding left and right to view products → Comprehensive management level According to the production and operation of the company, set a scientific and reasonable organizational structure, with the general manager as the main manager, and the chief engineer and production director as the subordinate, respectively responsible for the technical management and production quality management of the company; Eight departments are set up, including the Production Department, the Commerce Department, the Engineering Department, the Design and Research Department, the Quality Control Department, the Procurement and Supply Department, and the Administrative Personnel Department.

The company has an independent design research and development department and laboratory, with 18 technicians, including 1 professor level senior engineer, 3 senior engineers, 5 intermediate engineers and several assistant engineers, and relies on Baoye National Research Institute and Baoye Architectural Design Institute (Class A) for technical support.

Project case ← Slide left and right to view the project case → Zhuji Mali Village Project Baoye New Bridge Style Project Vanke Investment Promotion • Yongrong Huafu Project Shanghai Wanhua City Project Zhejiang University of Technology Zhijiang College New Project Communication address: Longxin Group Jiangsu Construction Industry Co., Ltd., No.

889 Qunxian West Road, Keqiao District, Shaoxing City The Company, a wholly-owned subsidiary of Longxin Group, was established at the end of 2012 and is a production base for prefabricated components of building industrialization with domestic first-class modern production equipment.

The company has formed a replicable management mode through the construction of standardized system, and has successively incubated Nanjing Yusen Jianke Production Base, Xuyi Guolian Longxin Production Base and Wuhan Longxin Jianke Production Base, forming the layout of Longxin Group’s construction industry covering the Yangtze River Delta region and the direction of expansion along the upper reaches of the Yangtze River.

Longxin Group was approved as one of the first batch of national assembly demonstration bases and Jiangsu construction industry integrated application and component production demonstration bases, and was awarded as Jiangsu high-tech enterprise.

The site equipment industry company covers an area of 230 mu, with a total investment of 400 million yuan.

The first phase of the project covers an area of 100 mu, including 13000 square meters of main plant, 20000 square meters of storage yard, mixing plant and stock yard, experimental building, office building, complex building, warehouse, staff dormitory, etc; The second phase plant covers an area of 26000 square meters, the storage yard covers an area of 35000 square meters and other production supporting buildings..