/ / official account official of WeChat / NOCITCE / WeChat changed the push rule because of the official account of WeChat.

If you do not want to miss the highlight of this official account, please set the public address of the construction technology as the star sign and click “collect”, “look at” and “Zan” at the end of the text, so that each new article will appear in the subscription list at the first time.

Star setting: enter the official account homepage and click on the top right corner.

Click Set as star, Yellow Pentagram will appear next to the official account.

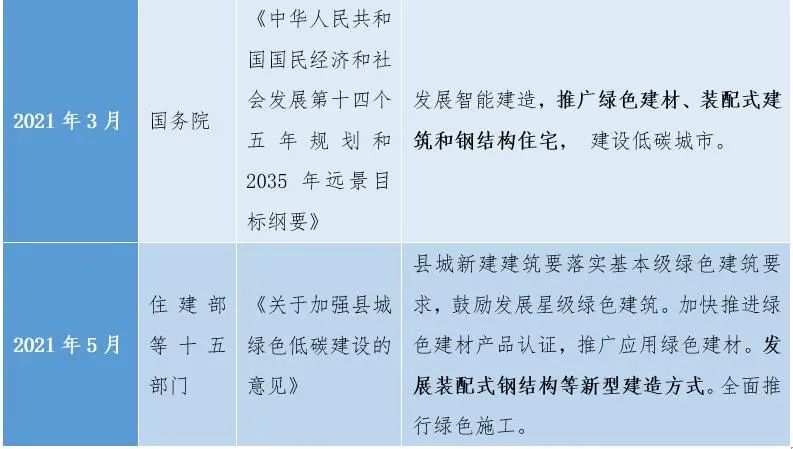

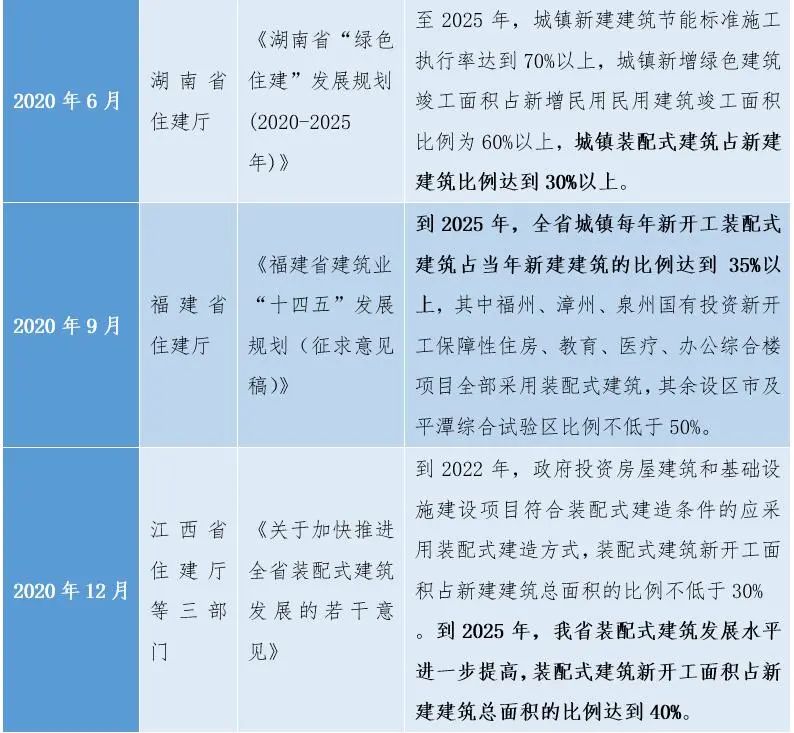

(Android and IOS users operate the same) from 2020 to the end of September 2021, the Ministry of housing and urban rural development of the people’s Republic of China and the housing and urban rural development departments of provinces and cities issued more than 20 incentive policies related to precast buildings.

While giving relevant support and preferences to precast construction enterprises, they also put forward requirements for the proportion of precast buildings in new buildings.

Precast buildings are built by assembling precast parts on the construction site Build.

In recent years, the cast construction industry has grown rapidly and the market scale is rising.

In 2020, the newly added precast building area in China was 630 million square meters, with a year-on-year increase of 50.72%.

The compound growth rate in recent four years was 53.32%, accounting for about 20.5% of the newly added building area.

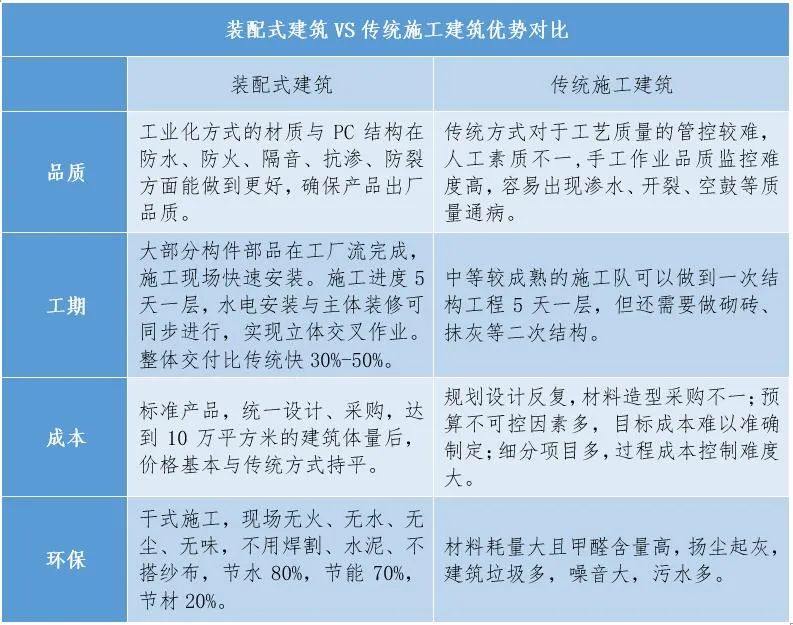

Compared with traditional buildings, precast buildings have incomparable advantages in building quality, construction period, energy conservation and environmental protection.

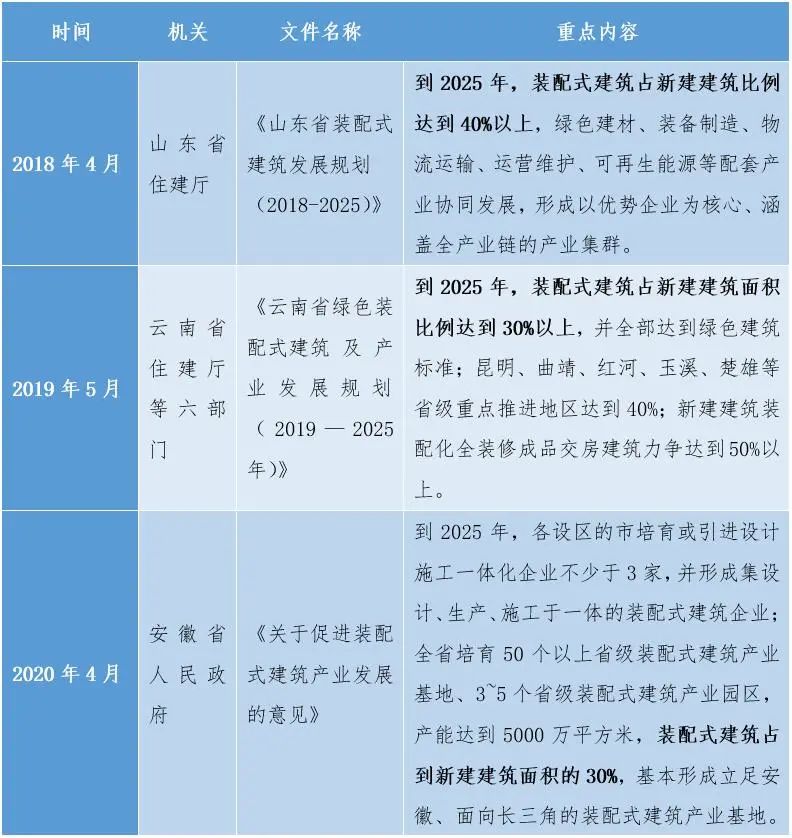

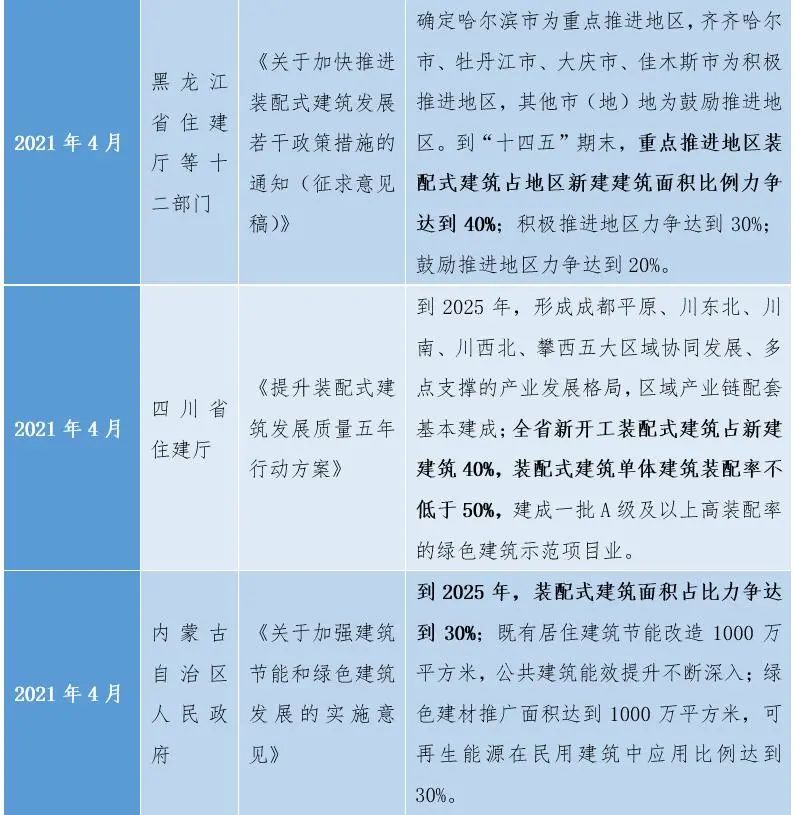

02 industrial policies 2.1 compilation of policies related to precast buildings (policies at the national level since 2020) 2.2 development goals of precast buildings across the country.

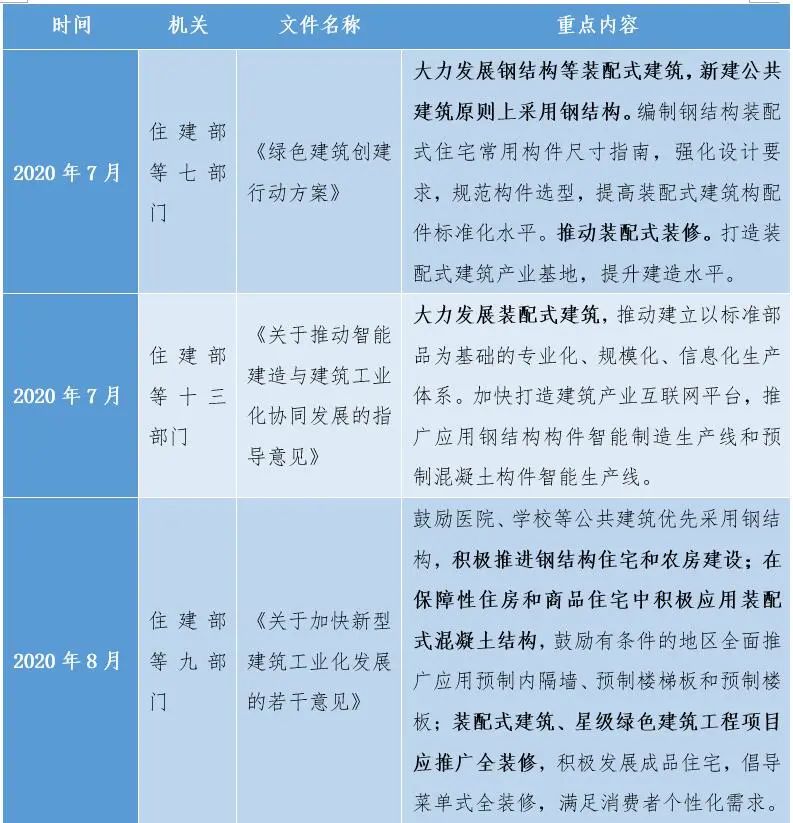

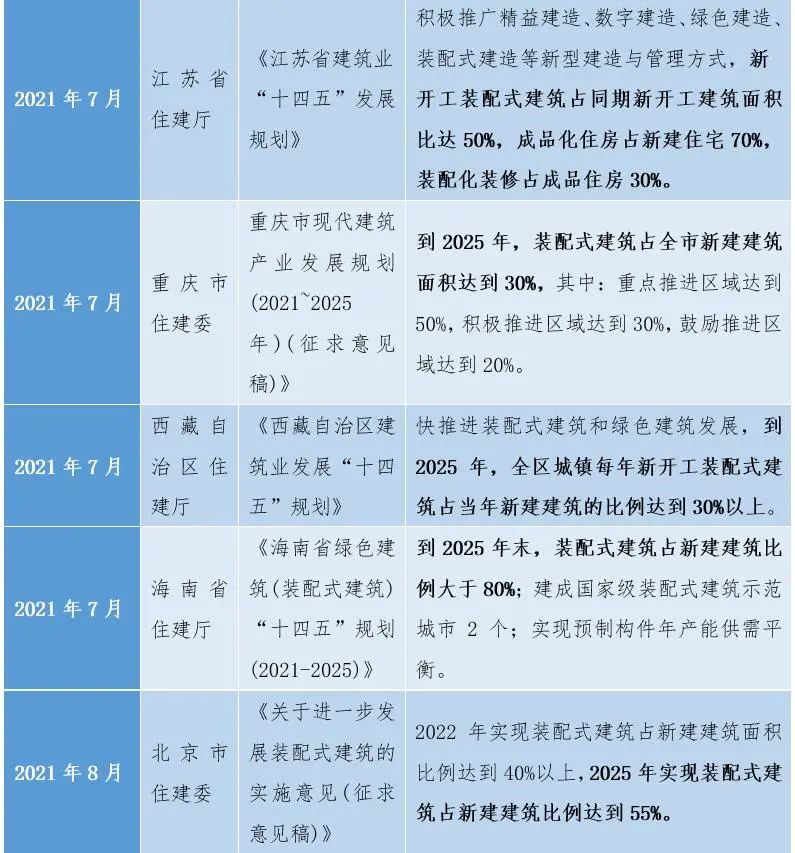

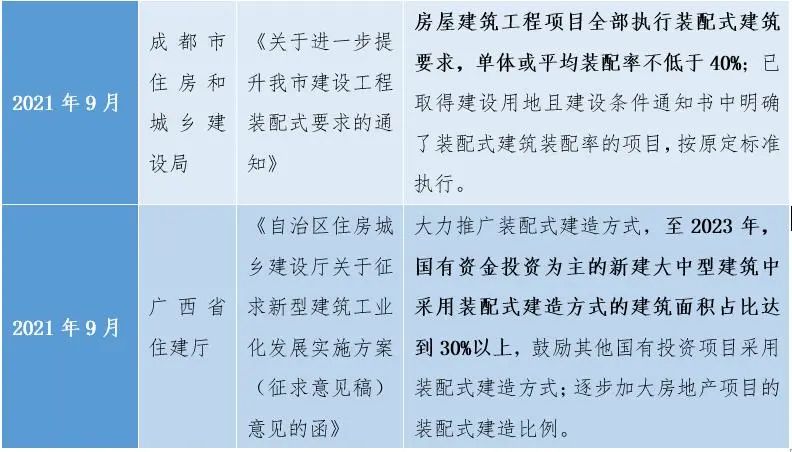

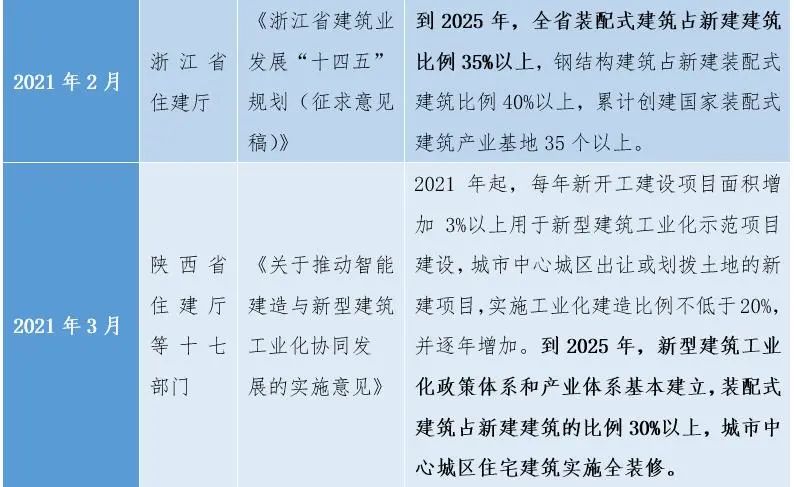

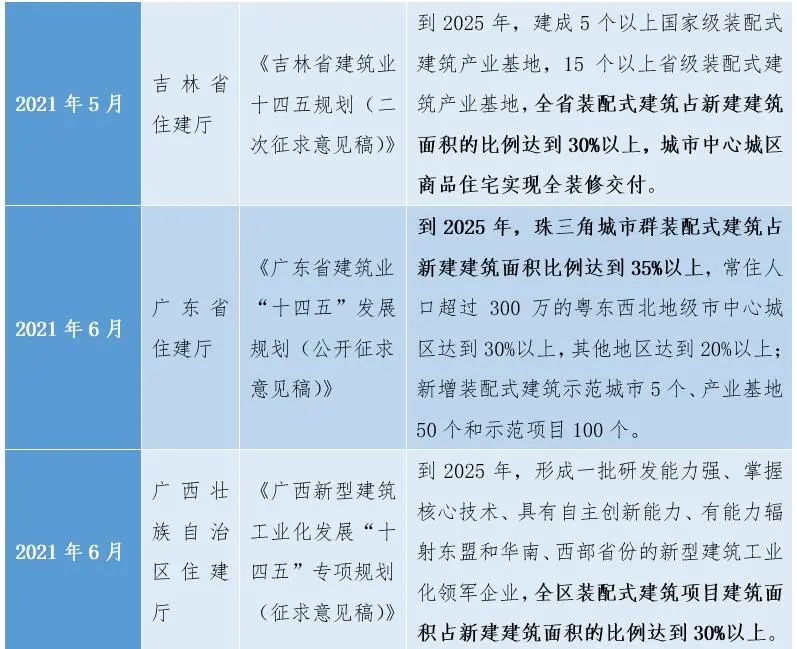

With the introduction of national policies, provinces have successively launched the “14th five year plan” The development goal of the local precast construction industry during the period.

According to relevant documents, by the end of 2025, the proportion of precast buildings in the new construction area in Hainan Province will be the highest, 80%; Beijing and Jiangsu followed, with target ratios of 55% and 50% respectively; Except that Ningxia Hui Autonomous Region has set the assembly target at 25%, other regions have set the ratio in the range of 30% – 40%.

03 moderately cast formwork system under the influence of the environment, the moderately cast formwork system launched by Changyi aluminum formwork advocates the prefabrication of steel formwork at complex locations, such as the prefabrication of steel formwork at stair locations in advance, which can reduce the large amount of time spent in the construction of aluminum formwork, and save the construction period and cost for the project.

Secondly, the system advocates the use of on-site prefabrication, which is more flexible than factory prefabrication and can be adjusted quickly according to the project conditions.

If the project does not have on-site prefabrication conditions, the nomadic prefabrication concept can also be adopted to reduce the possible damage and cost of precast components in transportation.

Precast stairs, of course, the moderately cast formwork system is also conducive to reducing the operation cost of the aluminum mold factory under the condition of saving the total contract cost.

The project effectively reduces the non-standard rate through the prefabrication of steel formwork at complex positions.

In addition, the non-standard flat plate at the project node can further reduce the non-standard rate by using aluminum frame wood and aluminum frame plastic mold, which can effectively reduce the operating cost of the leasing enterprise.

Secondly, the aluminum mold market tends to be saturated in recent years.

Aluminum mold factories try to use turnover plates instead of continuing to produce and use new plates.

An appropriate cast template system can effectively promote the restructuring of the company’s turnover plates, make more templates turnover, and relieve the company’s pressure from the source..