Chips are known as the jewel in the crown of the electronic information industry.

A few days ago, the US government announced a ban on US companies from conducting business contacts with Huawei.

One of the big sticks that Trump wielded was the “chip”.

He concluded that without chip support, China’s information industry would obediently surrender.

However, Trump’s biggest mistake was that he underestimated the intelligence of the Chinese people.

Huawei quickly came up with alternative solutions and told the world that we Chinese people have enough wisdom and determination to do everything well, including making a good chip.

In fact, Made in China has become a business card that we are proud of in the world.

The reason for this lies not only in our excellent equipment, but also in our advanced concepts, daring to unleash our imagination, and achieving the ultimate in everything.

This is what we often refer to as the ‘spirit of craftsmanship’.

Recently, the small component yard of the Beijing Tang Railway built by China Railway 14th Bureau Group has attracted attention in the industry.

They concentrated and mass-produced small prefabricated components such as bridge railings, shutters, and cover plates, and adopted the organizational form of modern factories for mechanized assembly operations.

This not only greatly improved the yield of prefabricated components, but also accelerated construction efficiency, which was recognized by the construction unit.

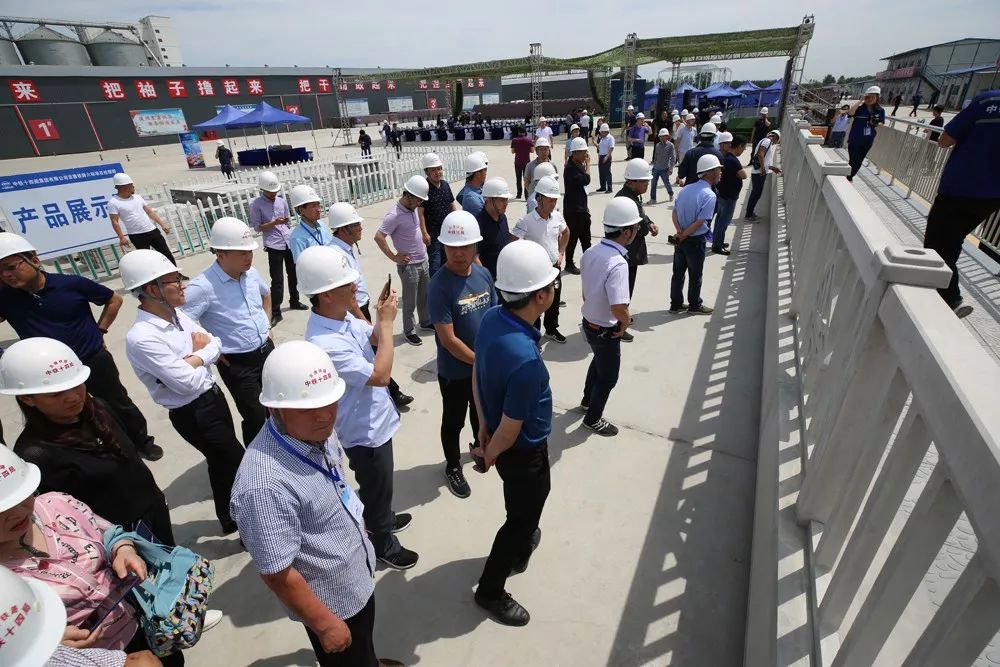

On the morning of May 22nd, the Beijing Tianjin Hebei Railway Investment Company organized management personnel and representatives of various participating units from subordinate railway projects such as Beijing Tang, Beijing Bin, and Beijing An to visit the construction site of the Beijing Tang Railway Project Department of China Railway 14th Bureau to observe the production process of small prefabricated components on site.

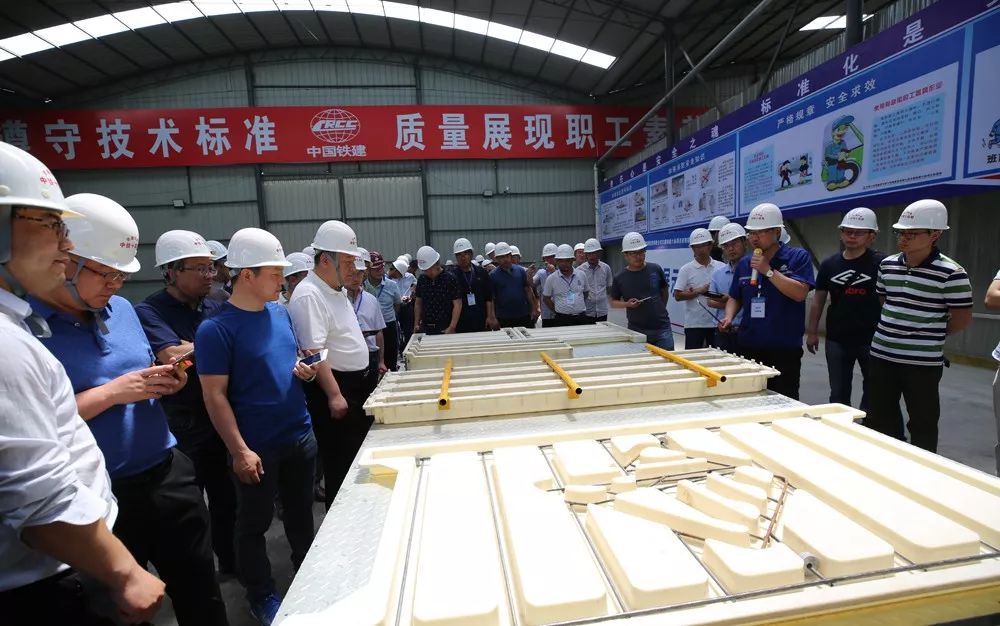

More than 120 attendees walked into the production workshop and carefully examined the entire production process of small prefabricated components.

In the workshop, they saw that the factory area was clean and tidy, with various raw materials and semi-finished products arranged in an orderly manner.

What they focus on is the application of various automated CNC mechanical equipment.

Workers only need to manipulate buttons or equipment to achieve automated flow operations from steel production to concrete pouring.

Li Rongjie, Director of the Engineering Management Department of the Beijing Tianjin Hebei Railway Investment Company, the construction unit, highly praised the construction situation and technological breakthroughs of the small prefabricated component yard.

He pointed out that the standardized construction level of the small prefabricated component yard on the Beijing Tang Railway is high, the process and construction methods are scientific and reasonable, and the safety and civilized construction management is in place.

As you can see, the concrete for pouring prefabricated components is transported from the tank truck to the mold, and the entire process is automatically transmitted using flow equipment, greatly improving the pouring efficiency and effectively ensuring product quality.

Meanwhile, during the entire construction process, the concrete basically does not fall to the ground, which not only reduces the waste of concrete but also maintains the cleanliness of the site

.