▲ Click the card above to focus on the “prefabricated construction network” prefabricated construction network prefabricated building industry platform.

Learn about the latest developments in the prefabricated building industry every day! 871 original content official account introduction With the in-depth development of vigorously promoting prefabricated building in China, the development and innovation of precast concrete technology and products has become a hot spot of architectural technology innovation in recent years.

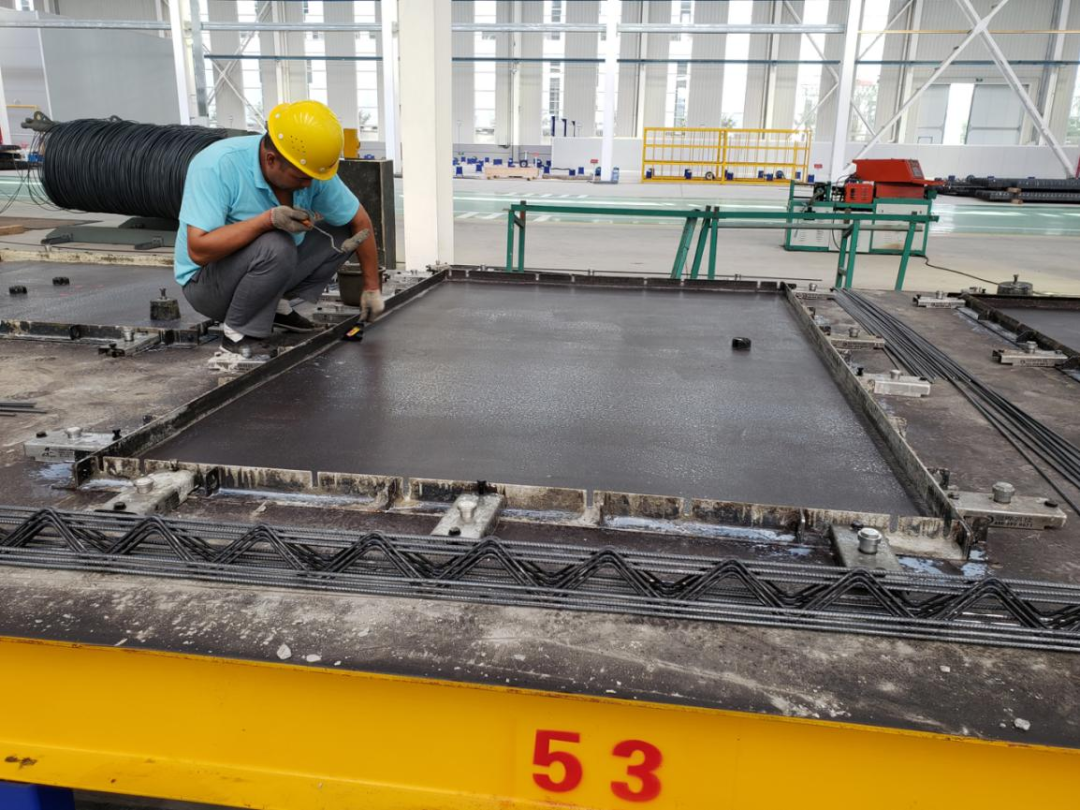

Precast concrete components, as the basic components for the development of prefabricated building, assembling integral wall, slab, beam, column, staircase and other supporting components has become the main product of building industrialization.

In this situation, various quality issues continue to arise with precast concrete, which troubles the construction and use processes.

And in the entire concrete project, concrete curing is the sub project that takes the longest time and has the greatest impact on concrete quality.

The quality of precast concrete slabs determines the service life of prefabricated buildings, which puts forward higher requirements for the maintenance of precast concrete slabs.

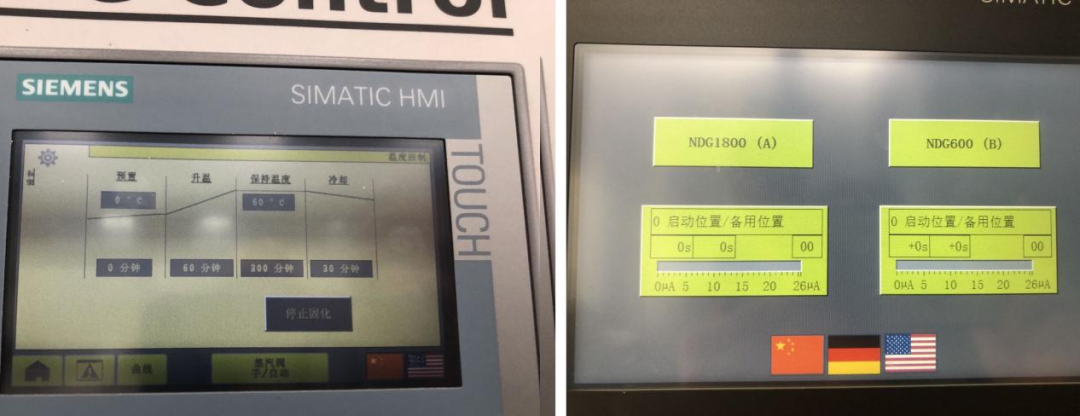

Below, through examples, we will discuss how the intelligent maintenance system combination solution can meet the flexible production and maintenance needs of prefabricated factories, as well as how to prevent and solve problems and treatment measures that occur in the production of prefabricated concrete PC components.

Project Overview: Tianjin Hejia Metal Industry Construction Industrialization Co., Ltd.

(referred to as Hejia Metal Industry) has a total investment of 360 million yuan in the Ninghe Industrial Base, covering an area of 160 acres.

Hejia Metalworking is committed to promoting the industrialization of prefabricated building and the industrialization of prefabricated building.

The products of building industrialization mainly include: prefabricated laminated boards, prefabricated stairs, exterior wall panels, interior wall panels, partitions, balconies, etc.

There are two prefabricated component production lines in Xindi, Hebei, one is the laminated board production line and the other is the comprehensive production line.

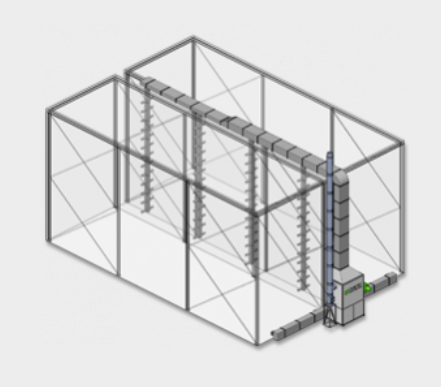

Each production line has 2 face-to-face warm air curing kilns, totaling 4 curing kilns with over 140 fixed formwork.

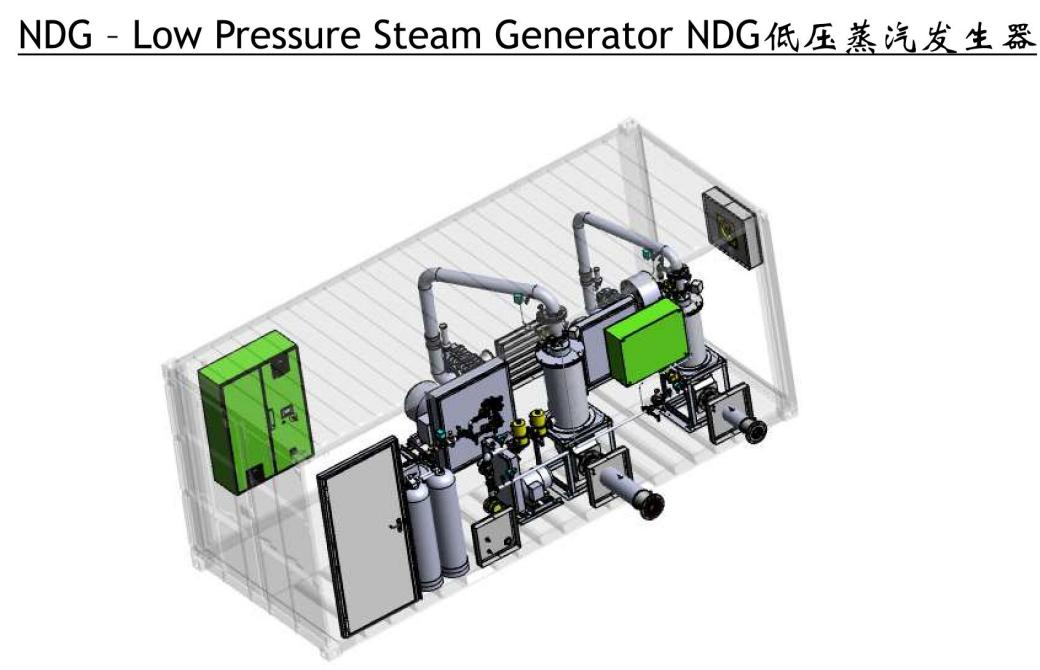

If the production scale of precast concrete slabs is large and traditional steam boiler maintenance is used, the cost and later maintenance and usage cost will be a significant expense; Secondly, boilers are special equipment that require declaration, annual inspection, and construction of boiler rooms.

If the boiler room is located far from the workshop producing precast concrete slabs, steam will lose some of its heat during transportation, resulting in energy waste and often limited by existing space and distribution, resulting in low equipment utilization; Finally, during the production process, if the operator cannot accurately control the curing temperature, humidity, and rise/fall rate of the precast concrete slab, the quality of the product is also difficult to guarantee

.