Editor’s note: as we all know, the core component of prefabricated buildings is prefabricated components.

In other words, the quality of prefabricated components determines the quality of dressed and matched buildings.

The production of prefabricated parts with excellent quality and accurate docking is inseparable from manufacturing equipment.

Prefabricated component production equipment (PC production line) goes first, so as to ensure “building a house like producing a car” from the source Become a reality.

Recently, at the 9th Asian international building industrialization exhibition, the editor of prefabricated building network had the honor to interview Mr.

Gao Jiedong, marketing director of Hebei Xindadi electromechanical Manufacturing Co., Ltd., which made us feel the advanced product technology and management concept of this enterprise in prefabricated component production equipment.

Gao Jiedong, marketing director of Hebei Xindadi electromechanical Manufacturing Co., Ltd., started from customer needs, Customized service: Hebei Xindadi electromechanical Manufacturing Co., Ltd., founded in 1997 Xindadi (hereinafter referred to as Xindadi) is a professional service provider of industrialized production technology and complete sets of equipment for precast concrete components, with 15 years of experience in the development of precast concrete component production equipment.

Xindadi has started the R & D and manufacturing of precast concrete component production equipment since 2005, providing complete sets of equipment for the construction of China’s first high-speed railway; it has entered the construction industry since 2012 With the promotion of national policies, the road of industrialized development has provided more than 600 prefabricated component production lines of various types for more than 400 domestic enterprises.

At present, Hebei Xindadi continues to focus on the production equipment of precast concrete components in many fields.

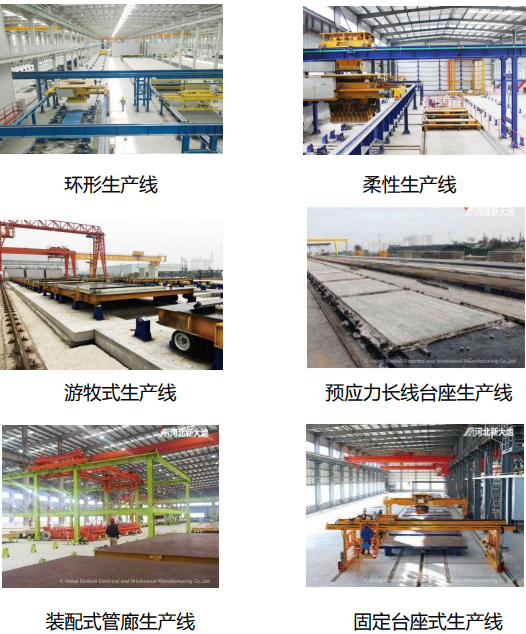

In the field of building industrialization, it has owned streamlined production system, fixed pedestal production system, flexible production system, nomadic production system, long-line production system of prestressed components, expandable combined production system, etc; In the field of Railway Construction: it has prestressed sleeper production system, double block sleeper production system, track slab production system, etc; In the field of Municipal Engineering: it has small and medium-sized component production system, prefabricated superimposed assembly pipe gallery production system, integral assembly pipe gallery production system, etc; Provide mold design and manufacturing in various fields.

Gao Jiedong, the company’s main product, told us in the interview: “the equipment provided by Xindadi is customized according to the needs of customers.

For example, we can carry out customized planning and design according to the output requirements of customers, investment scale, including the size of land, and even the particularity of production products, which is a major feature that our company is different from other equipment manufacturers.” 1.

Generally speaking, the construction cycle of nomadic production line is long and the cost of one-time investment is large.

In order to solve the above problems, reduce the transportation cost of components, and strive to complete the production task of prefabricated components with the shortest construction time, the best economic benefits and the smallest equipment investment, nomadic PC factory came into being.

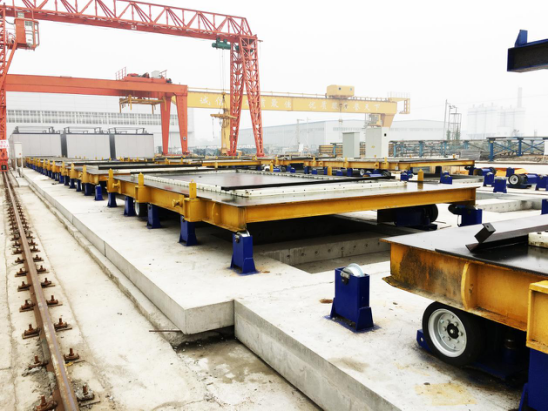

Gao Jiedong said: “based on the experience of prefabrication of railway double block sleepers and other projects, Xindadi has developed a nomadic PC production line.

The design of this nomadic PC production line is mainly characterized by the equipment foundation of prefabricated parts, reusable transfer, fast on-site installation speed, relatively low investment, easy relocation and rapid transfer.” At present, Xindadi’s nomadic production line has been applied to afuzhun railway station building in Xinjiang, Fujiu in Jiangsu, Changping in Yantong, Beijing, Houlu and other projects.

Nomadic production line of Beijing Yantong building components Co., Ltd.

2.

Expandable combined long line pedestal production line.

In addition, the expandable combined long line pedestal production line is also developed and produced by Xindadi and implemented in shengteng science and Technology Industrial Park Co., Ltd.

of Shenzhen Shantou Special Cooperation Zone.

The first mock exam is the long line pedestal and 140 meter long production technology, which is the first self sustained, composable, arbitrarily divided and nomadic long line pedestal production line in China.

It can produce prestressed concrete double T boards with different lengths, widths and heights.

Gao Jiedong said: “this year, we have provided the latest production line for CNBM in Qufu, Shandong Province.

It is a two span workshop and seven lines, of which three are 4m formwork and four are 2.5m formwork.

The whole length is more than 100 meters.

The equipment adopts the mobile mode.

At present, the production technology of the long-term platform is relatively mature for us.”.

Production line of shengteng science and Technology Industrial Park Co., Ltd.

in Shenzhen Shantou Special Cooperation Zone prestressed laminated plate production line of Shandong zhongjiancai Youke long line 3.

The construction of high-grade and modern products by fixed flexible production line requires a high degree of flexibility based on a solid technical foundation.

Xindadi has also developed a fusion product of efficiency and flexibility: fixed flexible production line.

The production system is based on the fixed mold production mode, combined with the efficient operation equipment in the assembly line, moves by itself through the track, so that these equipment can work on the fixed mold, and each mobile equipment can be transferred by the equipment ferry car, so that multiple production lines can share a set of equipment, Reduce the equipment investment and realize the efficient and flexible production of components on the fixed formwork.

The fixed flexible production line can be fixed in the plant for production, and can be moved to the construction site for nomadic production.

The production line can be used to produce various flat components, such as grouting sleeve shear wall, external wall hanging plate and prefabricated floor slab.

Components can be produced in a mixed way, with flexible production scheduling and low production energy consumption.

In terms of after-sales service, new earth has established offices in key areas of the country since the end of last year, such as Beijing, Tianjin and Hebei, the Yangtze River Delta and the Pearl River Delta.

Each office has 3 ~ 4 professional after-sales service personnel.

At the same time, Xindadi has built a spare parts warehouse in its offices to ensure that once there is a problem with the equipment in the PC factory, it can respond within one hour and arrive at the site to solve the problem within four hours..