① Installation of beam formwork: Process flow: leveling, marking lines (axis, horizontal line) → erection of support frame → formwork for column head → laying of bottom formwork → leveling by pulling wires → sealing of side formwork → pre inspection;.

② Installation of column formwork: pre installation inspection → template installation → diagonal inspection → length difference → installation of column clamps → comprehensive inspection and correction → overall fixation → column head repair;.

③ Installation of floor formwork: bracket erection → keel laying and reinforcement → installation of floor formwork → pre inspection;.

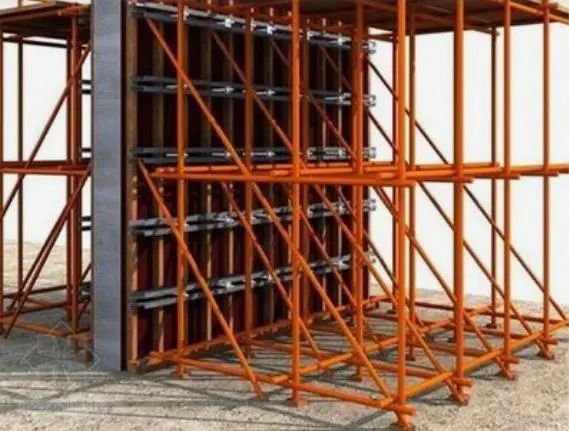

④ Wall formwork installation: Inspection before formwork installation → Support side formwork → Reinforcement binding → Install tension bolts → Support the other side formwork → Correct formwork position → Tighten tension (water stop) bolts → Support fixation → Comprehensive inspection..

① The large keel adopts 48 × 3.5mm double steel pipes, with a span equal to the spacing between the support poles; The small keel is made of 40mm x 80mm square timber with a spacing of 300mm, and its span is equal to the spacing between the large keels;.

② Laying of beam bottom formwork: Adjust the elevation of the support pole according to the design elevation, and then install the beam bottom formwork. The arch height at the middle of the beam span is 2 ‰ of the beam span. When the main and secondary beams are connected, the main beam arches first, and the secondary beam arches later;.

③ Laying of beam side formwork: install the beam side formwork, presser foot plate, slant support, etc. according to the ink line. The beam side formwork shall be provided with slant support. When the beam height is greater than 700mm, the waist ridge shall be set and reinforced with split bolts. The horizontal spacing of split bolts is 500, and the vertical spacing is 500;.

2. Before installing the column formwork, it is necessary to check whether it is flat. If it is not flat, a layer of cement slurry (10-20mm thick) should be added to the bottom of the formwork to prevent leakage of slurry during concrete pouring and cause root rot at the bottom of the column;.

① Using wood plywood as the floor template, the general method is to lay the entire piece and locally assemble small pieces. The template joints should be set on the keel; The large keel adopts 48 × 3.5mm double steel pipes, with a span equal to the spacing between the support poles; The small keel is made of 40mm x 80mm square timber with a spacing of 300mm, and its span is equal to the spacing between the large keels. A through line is hung to level the large keel, and the top elevation of the large keel is determined based on the elevation. Then, the small keel is erected and the formwork is laid;.

② After the floor formwork is laid, the support should be carefully checked for firmness, and the formwork beam and board surfaces should be cleaned thoroughly;.

① Before installing the wall template, it is necessary to clean up the debris inside the wall. The edge line of the wall and the template should be marked as the line, and the axis should be marked at the large corner of the external wall. A mortar leveling layer should be prepared or a sponge strip should be pasted at the bottom of the template to prevent mortar leakage;.

② Before installing the wall formwork, place the door and window formwork and embedded parts, and weld the limit reinforcement according to the wall thickness. It is forbidden to connect the inside and outside of the limit reinforcement of the basement exterior wall, but it should be noted that the main reinforcement of the wall cannot be burnt;.

③ The template installation starts from the middle of the external template to ensure the accuracy of the building’s external dimensions and verticality; After setting up one side of the formwork, the welded water stop bolts can be inserted, and then the other side of the formwork can be adjusted in position by aligning it with the hole holes of the through wall bolts for fixation. After the outer formwork is installed, the inner formwork can be installed;.

④ Before installing the template, the release agent must be evenly applied; When supporting the formwork, it is necessary to treat the joint of the formwork and stick double-sided tape at the joint of the panel; At the corner of the wall (external corner), attention should also be paid to the tight overlap of the two boards; Female corner mold.