Click the blue word to pay attention to our core tip: by 2020, the proportion of precast buildings in new buildings will reach more than 15%, of which more than 20% will be in key areas, more than 15% will be actively promoted, and more than 10% will be encouraged.

All localities are encouraged to set higher development goals.

Establish and improve the policy system, planning system, standard system, technical system, product system and supervision system of precast buildings, form a number of large-scale production enterprises and general contracting enterprises of precast building design, construction and parts, form a professional team of precast buildings, and comprehensively improve the quality, efficiency and quality of precast buildings, Realize the all-round development of precast buildings.

Since September 2016, the popularity of precast buildings has been rising.

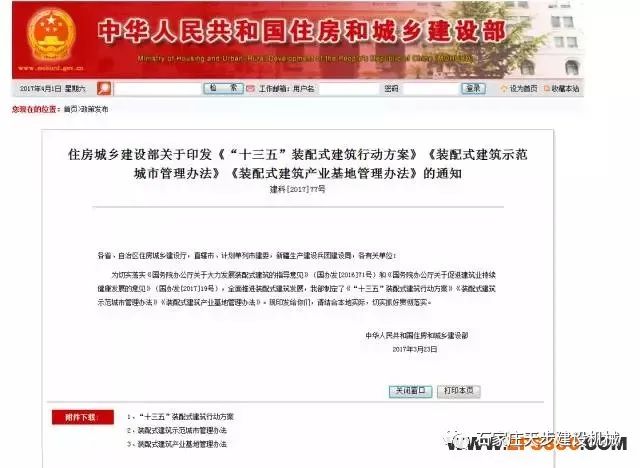

The State Council and the Ministry of housing and urban rural development have successively issued policy documents on vigorously developing precast buildings.

Recently, the Ministry of housing and urban rural development issued the action plan for precast buildings in the 13th five year plan, which clearly points out that by 2020, the proportion of precast buildings in new buildings will reach more than 15%, including more than 20% in key areas, more than 15% in actively promoting areas and more than 10% in encouraging areas.

Encourage all localities to set higher development goals.

Establish and improve the policy system, planning system, standard system, technical system, product system and supervision system of precast buildings, form a number of large-scale production enterprises and general contracting enterprises of precast building design, construction and parts, form a professional team of precast buildings, and comprehensively improve the quality, efficiency and quality of precast buildings, Realize the all-round development of precast buildings.

By 2020, cultivate more than 50 precast building demonstration cities, more than 200 precast building industrial bases, more than 500 precast building demonstration projects, and build more than 30 precast building scientific and technological innovation bases, so as to give full play to the leading and driving role of demonstration.

1.

What is a precast building? Precast building refers to the building formed by the assembly and connection of parts and components produced in the factory at the construction site.

2.

Several advantages of developing precast buildings: first, saving resources and energy; Second, reduce pollution; Third, improve labor production efficiency; Fourth, it plays a very positive role in improving project quality; Fifth, it can promote the deep integration of informatization and industrialization; Sixth, it can give birth to some new industries and generate some new kinetic energy for economic development; Seventh, it plays a positive role in resolving production capacity.

3.

Common construction problems of precast buildings: first, the corner plate is broken; Second, the laminated plate is broken; Third, the outer wall insulation layer is broken; Fourth, the grouting is not full; Fifth, sleeve connection dislocation, etc.

How to solve the problem of insufficient grouting of cast structure is the key to find the defect location! The problem of insufficient grouting of cast structures can be divided into: it is difficult to determine the grouting fullness of precast wallboards during longitudinal connection and the grouting holes of precast components are blocked.

It is generally believed that the grouting is completed when the concrete poured from the lower part flows out of the upper hole, but in fact, the internal situation of the grouting pipe is difficult to test and the grouting fullness is difficult to grasp.

In addition, the grouting hole will be blocked due to the careless operation of the component factory during component production and the unclean cleaning of the grouting hole by the on-site workers.

If the grouting of reinforcement sleeve connection and slurry anchor lap connection is not dense, it will directly affect the bearing capacity of building structure, and even cause malignant accidents such as potential safety hazards and collapse, resulting in huge social and economic losses.

Therefore, it is urgent to solve the problem of building grouting of equipment accessories! Shengtuo grouting compactness quality detector is the bane of grouting problems.

The equipment is mainly used to detect the grouting compactness of prestressed anchor cables (rods) such as bridges, tunnels and precast buildings, and can quickly and qualitatively detect the compactness of ducts; Grouting defects can also be located and identified.

Obtained a number of invention patents.

The qualitative test method uses the steel strand exposed at both ends of the anchor cable to test, and the test efficiency is high.

Since defects such as voids usually occur above the duct, it is usually only necessary to test the uppermost steel strand.

During one test, the above four methods (flea, flpv, PFTF and LaeA) can be completed at the same time, and the test time of one channel can be completed within 5 minutes.

Qualitative test schematic diagram positioning test: continuously test (excitation and trust) in the form of scanning along the upper or side of the pipeline, and test the condition of grouting in the pipeline through the characteristics of reflected signals.

Application case of positioning test of grouting compactness sleeve model and field test of cast shear wall (Shanghai) at the invitation of Shanghai Academy of Architectural Sciences, the design defects of sleeve concrete model were tested.

Model test 1.

50% design compactness of corrugated pipe restrained slurry anchor (casing diameter 35 ~ 50mm) and 100% design compactness 2.

50% design compactness of spiral stirrup restrained slurry anchor test (casing diameter 35 ~ 50mm) and 100% design compactness 3.

Conclusions and suggestions according to the test verification results, it can be concluded that: (1) two different types of slurry anchor fittings are made in this test, The results show that the lap has little effect on the test.

(2) For 20cm thick structures, similar results can be obtained by using different hammering and vibration.

It is more appropriate to comprehensively consider No.

10 and 17 hammers.

(3) The test results are consistent with most of the design, especially for 100% dense components.

Due to the influence of manufacturing process, although the specific location cannot correspond one by one, the slurry pouring amount is consistent, which can be verified by other methods.

(4) According to the test results, there is little difference between the single row plum blossom distribution and the middle distribution, and the position delay of double rows, especially sh8 and sh9 double rows are half empty and double rows are half empty a dense cavity is obviously distinguished..