In China, construction industrialization is in its infancy.

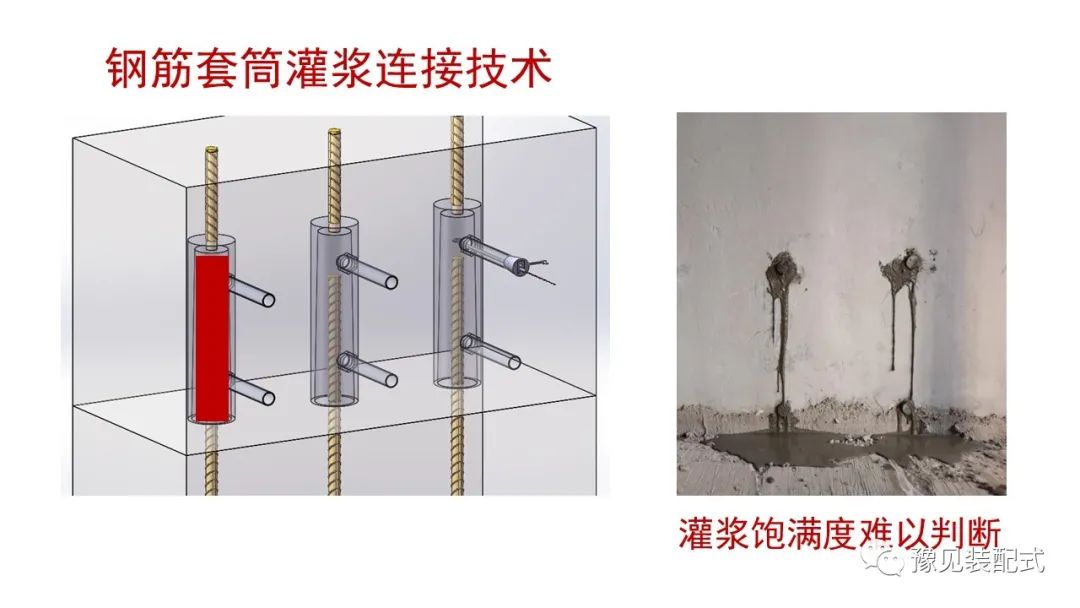

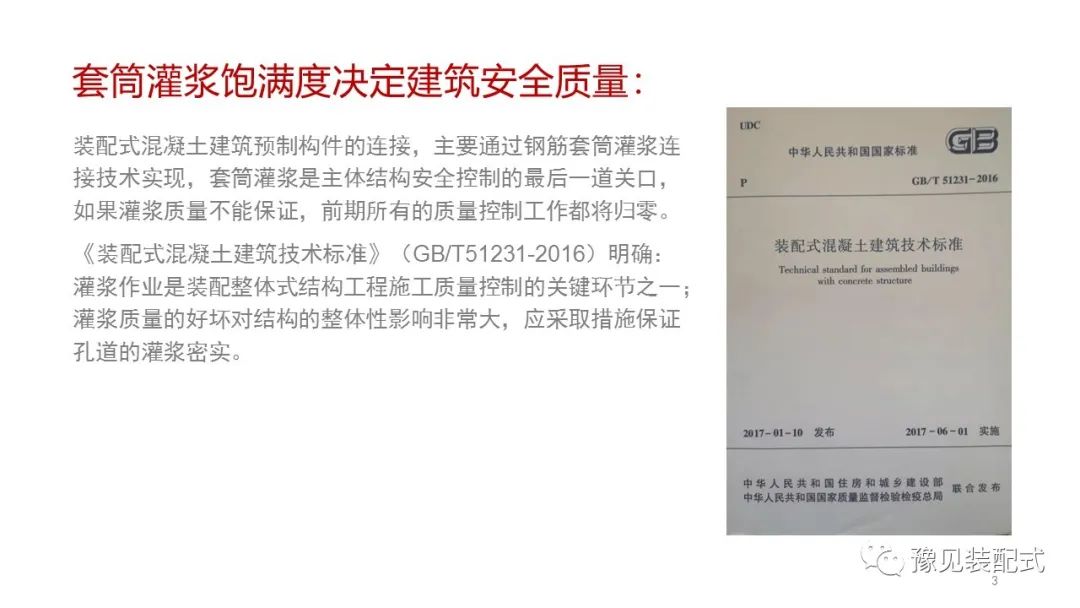

In addition to scientific design, the production of parts, materials and components should be ensured in order to build a good precast house, and the reinforcement sleeve grouting connection technology is one of the key technologies of precast concrete structure.

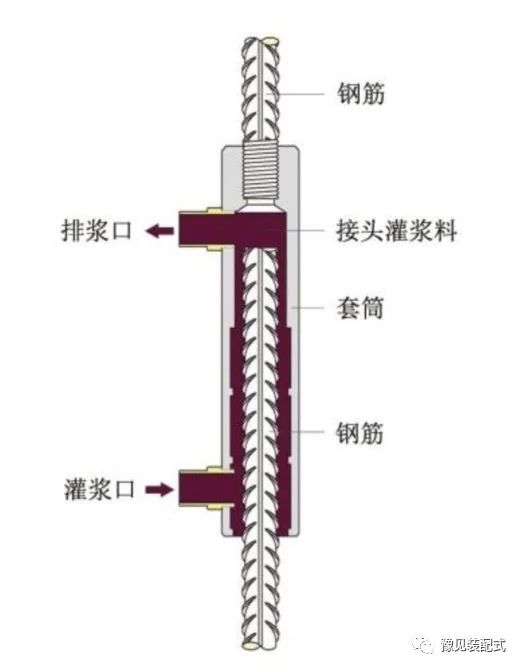

01 grouting sleeve technology introduction 1 characteristics (1) the joint adopts the composite connection type of straight thread and cement grouting, which shortens the joint length and simplifies the reinforcement connection production process of precast components; (2) The connecting sleeve is machined from high-quality steel or alloy steel.

The sleeve has high strength and good performance.

(3) A special grouting material for joint has been developed, which has large fluidity, long operation time, good early strength performance and high final strength.

2 scope of application and process principle this construction method is suitable for vertical reinforcement connection, including the connection of shear wall and frame column.

The connecting sleeve is made of high-quality steel with cavities at both ends.

It is connected with the threaded reinforcement by pouring special cement-based high-strength non shrinkage grouting material, and forms a reliable rigid connection.

Figure 1 and Figure 2 show the structure of half sleeve grouting and full sleeve grouting respectively.

Fig.

1 half sleeve grouting Fig.

2 full sleeve grouting 3 process flow and operation method 1) construction preparation grouting material (open the packaging bag and check that the grouting material should be free of moisture, caking or other abnormalities) and clean water; Prepare construction equipment; If the temperature is too high in summer, prepare ice to cool down and hot water in winter.

2) Basic process of preparing grouting material (see Fig.

3) Fig.

3 basic process of preparing grouting material (1) weighing grouting material and water: weigh grouting material and water respectively with an electronic scale in strict accordance with the water material ratio (e.g.

11%, i.e.

11g water + 100g dry material) required in the delivery inspection report of this batch of products.

Water can also be measured with a graduated measuring cup.

(2) First mixing: add water to the slurry measuring cup accurately.

First pour the water into the mixing bucket, then add about 70% of the slurry, and mix it with a special mixer for 1 ~ 2 minutes.

(3) Second mixing: add all the remaining materials and stir for 3 ~ 4 minutes until they are completely uniform.

(4) After stirring evenly, stand for about 2 ~ 3 minutes to make the bubbles in the slurry discharge naturally before use.

(5) Fluidity inspection: before grouting connection construction of each shift, the initial flow and fluidity of grouting material shall be inspected, and relevant parameters shall be recorded.

It can be used only after the fluidity is qualified.

When the ambient temperature of the detected fluidity exceeds the upper limit of the product service temperature (35 ℃), the actual operable time shall be inspected to ensure that the grouting construction time is completed within the operable time of the product, as shown in Figure 4.

Fig.

4 fluidity test Fig.

5 strength test (6) on site compressive strength test as required.

Before making the test piece, the slurry also needs to stand for about 2 ~ 3 minutes to make the bubbles in the slurry discharge naturally.

The test block shall be sealed and cured under the same conditions on site, as shown in Figure 5.

3) Basic process of construction grouting (see Fig.

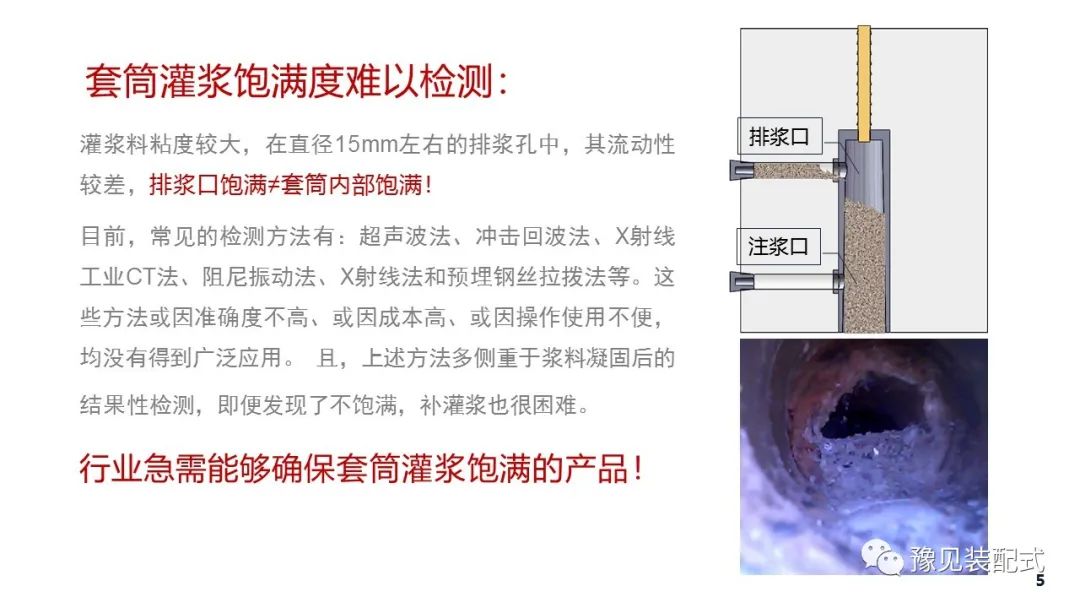

6) basic process of grouting (1) inspection of grouting hole and grout outlet hole: before formal grouting, use air compressor to check whether there are sundries affecting the flow of slurry in the grouting hole and grout outlet hole of each joint one by one to ensure that the hole path is unblocked.

(2) Construction grouting: ① through the practice of the project, the pressure maintaining pause grouting method can effectively save the construction waste of grouting materials and ensure the construction quality of the project.

Use the grouting pump (gun) to pressure grouting into the sleeve from the grouting hole under the joint.

Special attention shall be paid to that the normal grouting slurry shall be poured within 20 ~ 30 minutes from the beginning of water mixing, so as to reserve a certain operation emergency time as far as possible.

② The grouting hole and outlet hole shall be sealed with special plastic plug (matched with the hole), which shall be tightened with a screwdriver during operation.

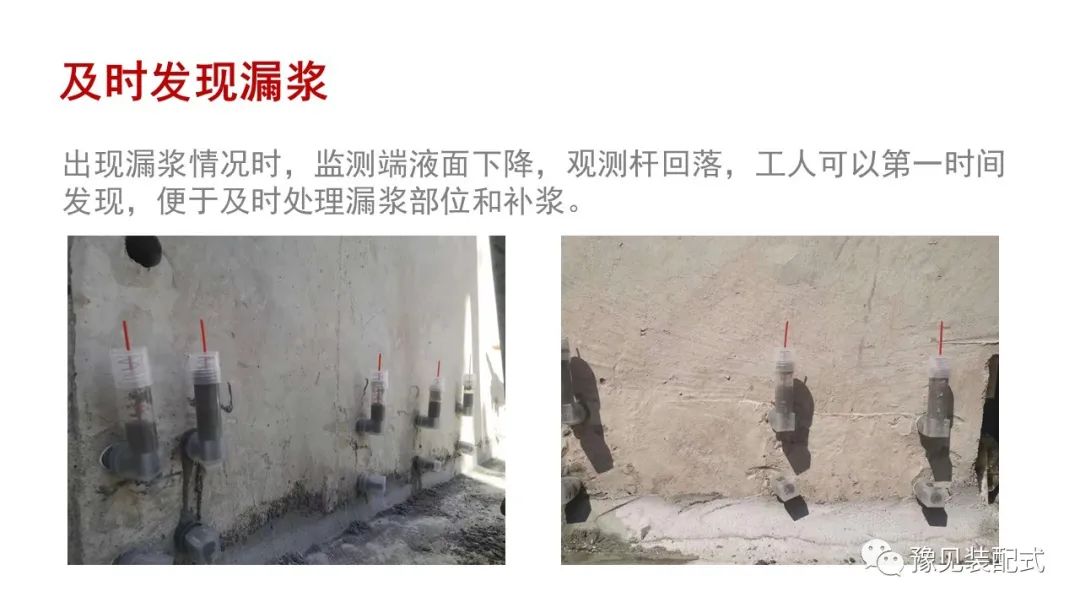

The grouted joints shall be inspected before grouting and slurry setting, and any slurry leakage shall be handled in time.

(3) Joint filling inspection: after the grouting material is solidified, remove the sealing rubber plug of the grouting and drainage hole.

The upper surface of the solidified grouting material in the inspection hole shall be more than 5mm higher than the lower edge of the drainage hole, as shown in Figure 7.

Fig.

7 joint filling inspection 4 machines and tools for grouting construction are shown in the table.

5 quality standards and testing methods if the grouting material used in the component factory to test the tensile strength of the grouting sleeve is the same as that used on site, and the test piece is also made to simulate the construction conditions, then the test does not need to be done again, otherwise it will be redone.

Inspection quantity: for grouting sleeves of the same batch number, type and specification, the inspection batch shall not be greater than 1000, and 3 grouting sleeves shall be randomly selected from each batch to make centering joints.

Test method: conduct tensile test in a qualified laboratory.

6 safety measures (1) special technical training and safety education must be carried out for grouting construction personnel to make them understand the construction characteristics of the new material, be familiar with the relevant provisions of the specification and the safety technical operation procedures of the post, and work after passing the examination.

The main construction personnel shall be relatively fixed.

(2) Full time safety and quality inspectors with safety technical knowledge and familiar with specifications must be equipped during grouting construction.

(3) When the grouting material is removed, the material must be free from dampness and blocking, and meet the requirements of the operating rules.

7 benefit analysis (1) reinforcement sleeve grouting technology is a key point in the field construction of cast structure.

Effectively solve the engineering grouting quality and shorten the construction period.

(2) Material and labor costs are saved.

The use of pressure stabilizing grouting method effectively eliminates the waste of engineering materials, which can save more than 40% of materials compared with other operation methods.

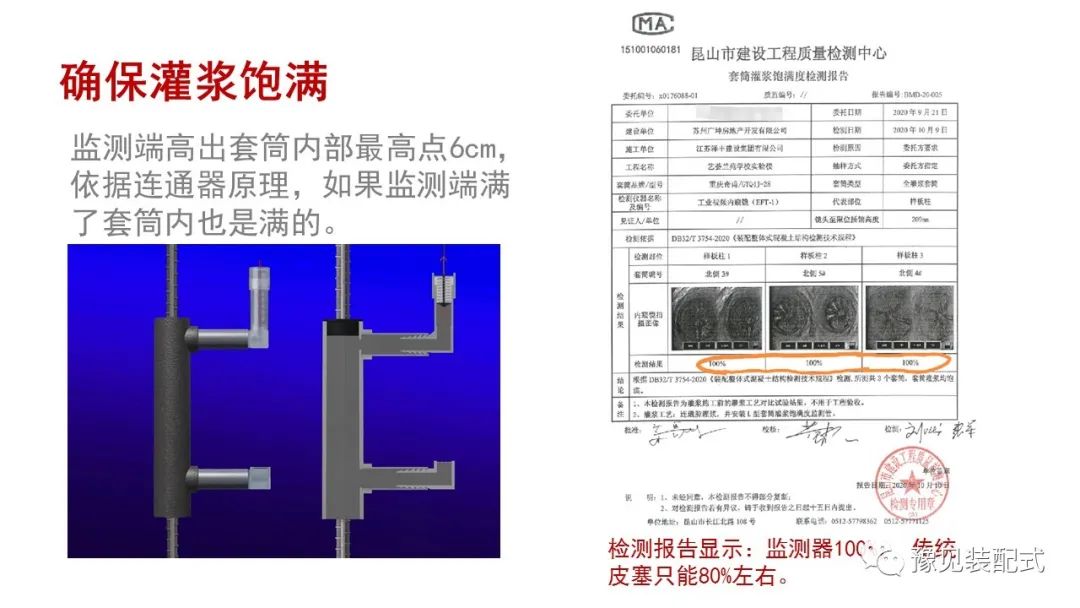

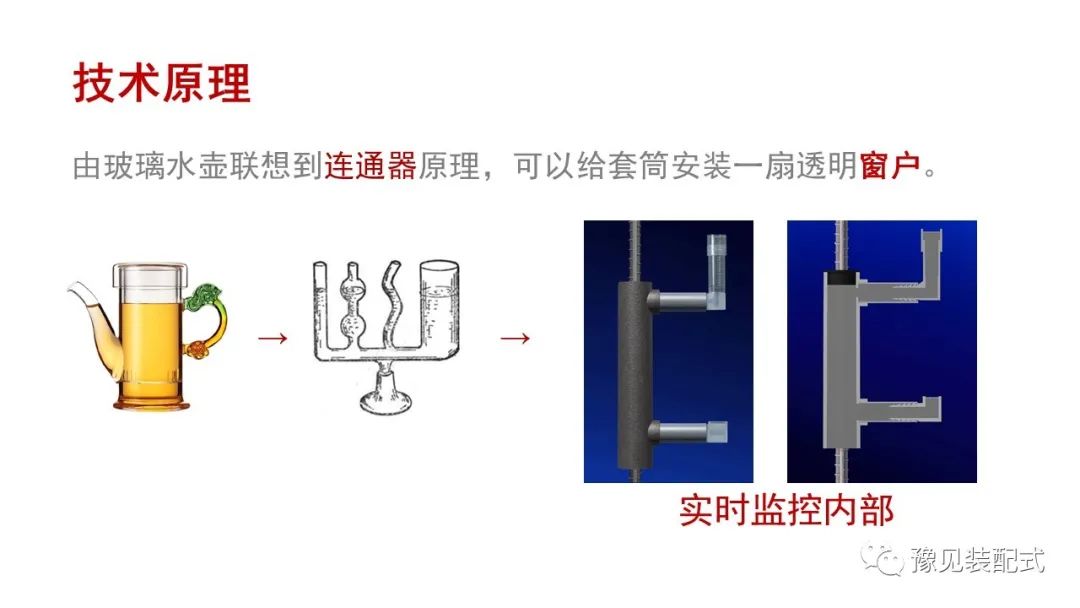

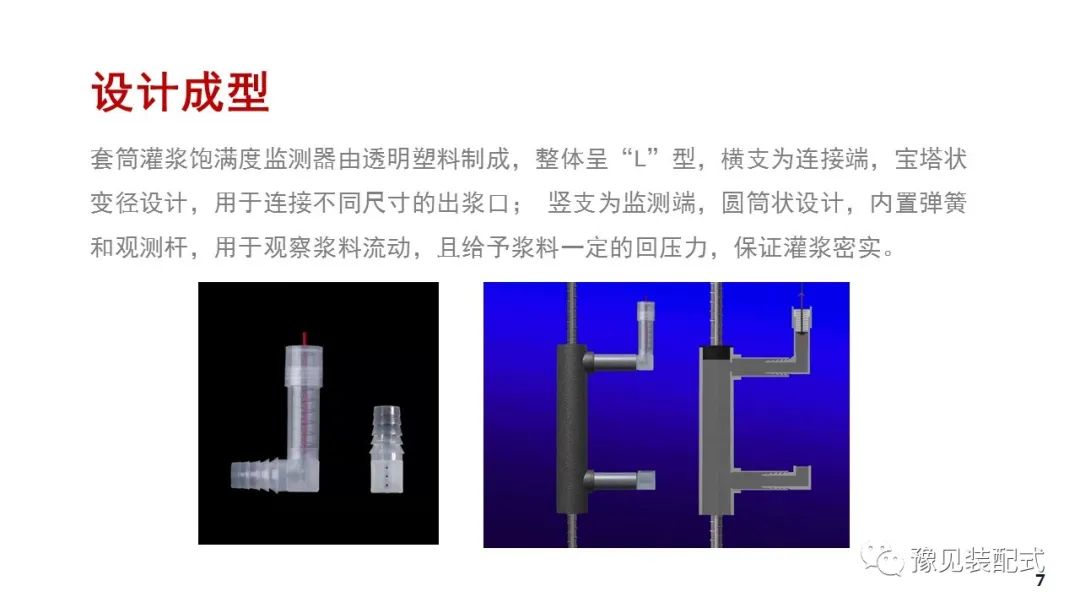

02 material source of sleeve grouting plumpness detection system: see assembly type..