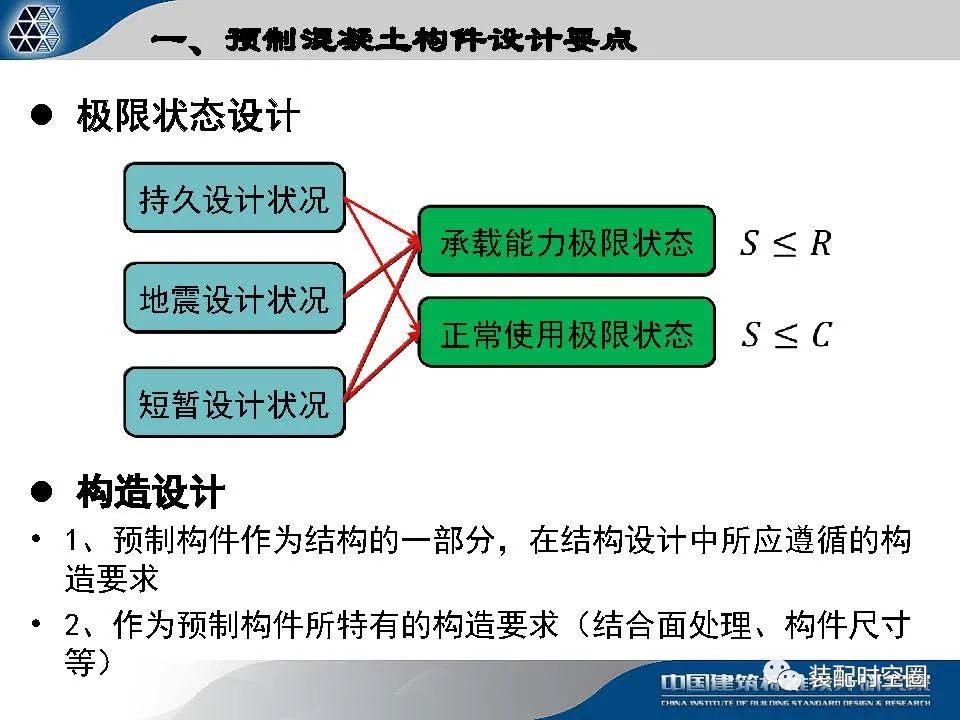

● structural design: 1.

Structural requirements to be followed in structural design of precast components as a part of the structure; 2.

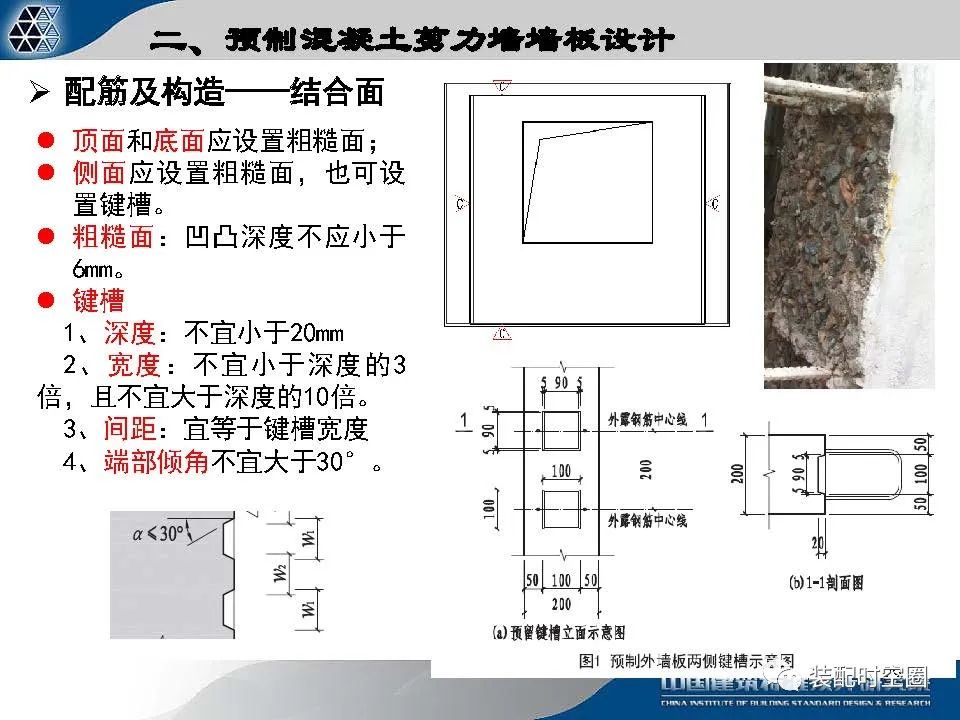

As the unique structural requirements of precast components (joint surface treatment, component size, etc.).

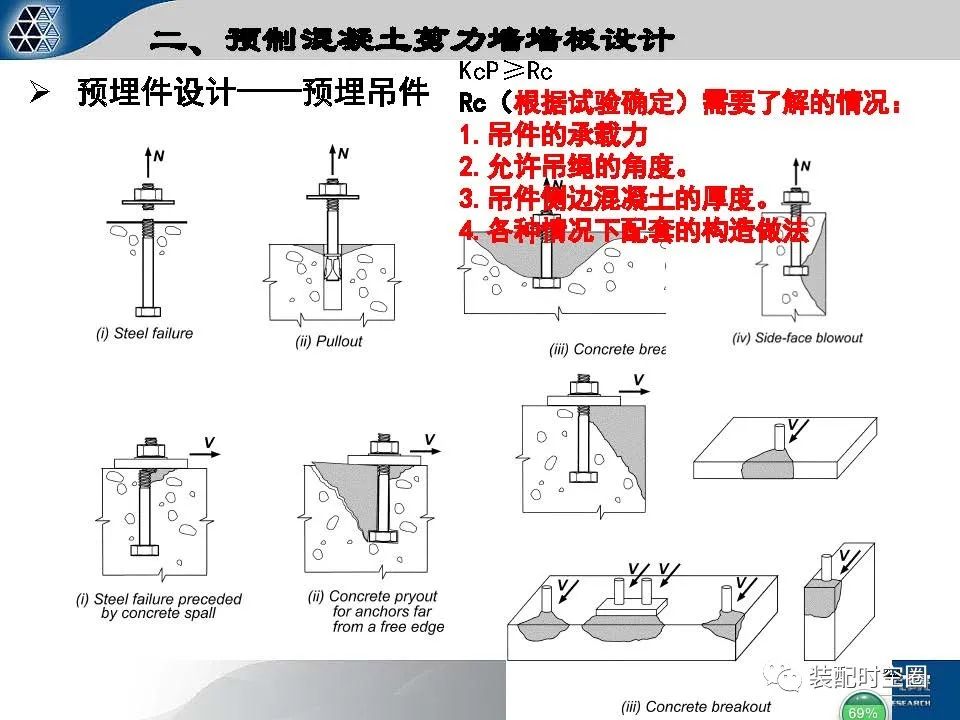

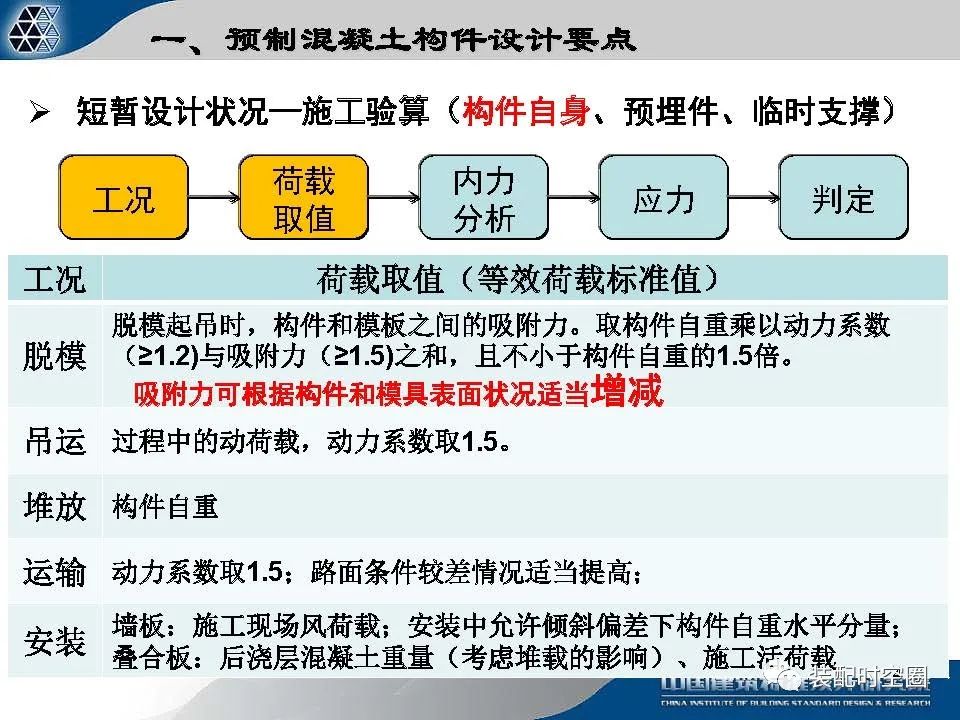

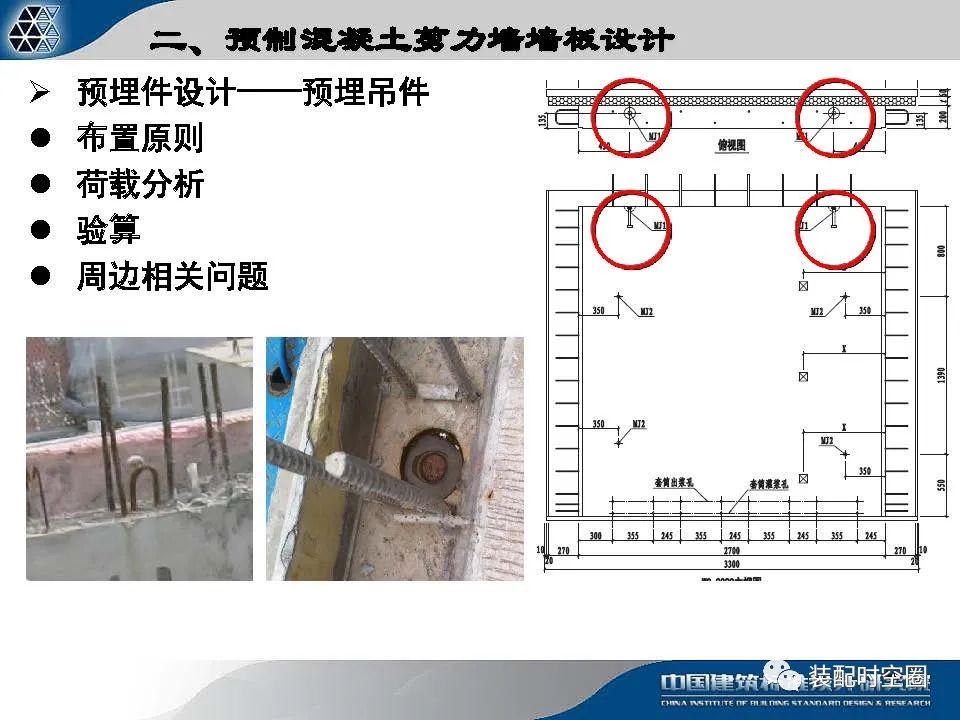

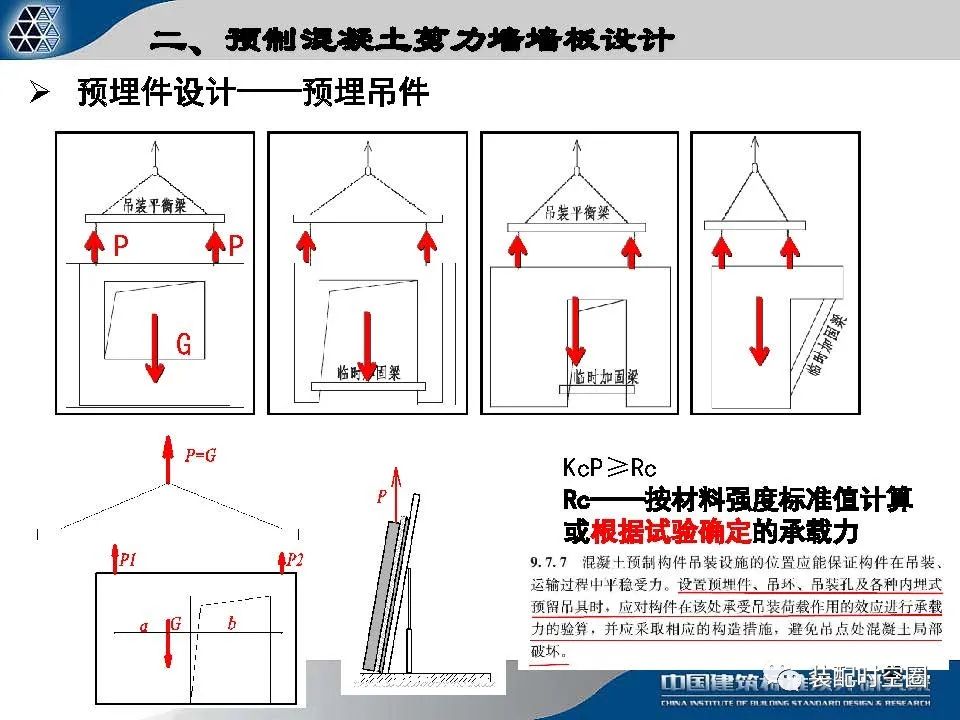

● demoulding: the adsorption force between components and formwork during demoulding and lifting.

Take the self weight of the member multiplied by the sum of the dynamic coefficient demoulding (≥ 1.2) and adsorption force (≥ 1.5), and it shall not be less than 15 times of the self weight of the member.

The adsorption force can be appropriately increased or decreased according to the surface conditions of components and molds.

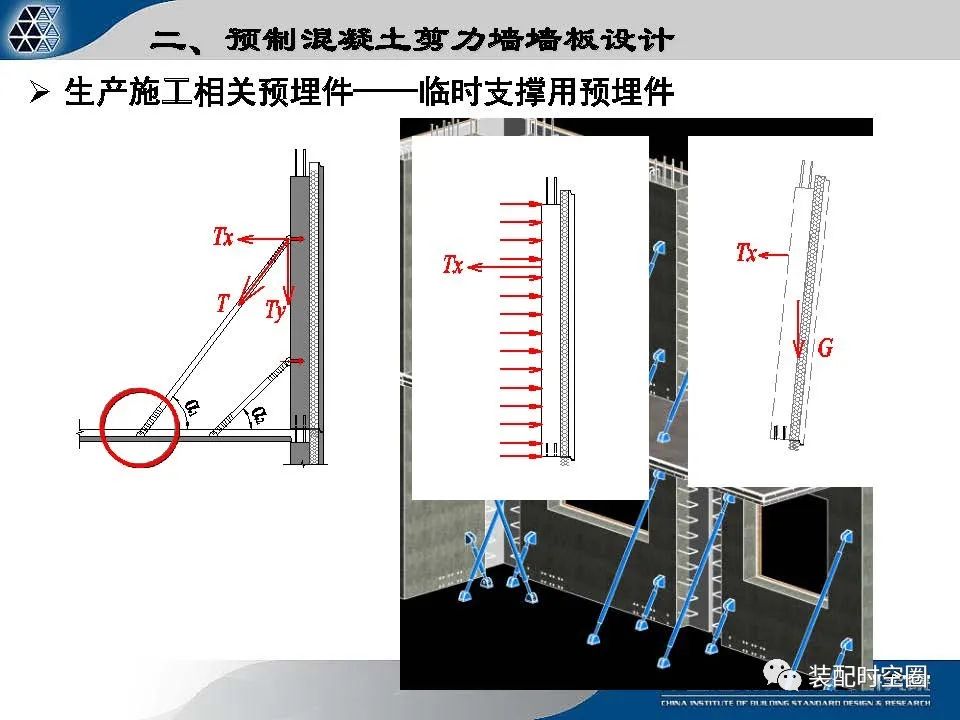

● hoisting: dynamic load in the process, the dynamic coefficient is 1.5 ● stacking: the dynamic coefficient of component self weight transportation is 1.5; The pavement condition is poor, which shall be properly improved; ● installation: wallboard: wind load on the construction site; During installation, it is allowed to tilt downward, and the component shall take care of its own horizontal component; Laminated slab: concrete weight of post cast layer (considering the influence of surcharge) and construction live load.

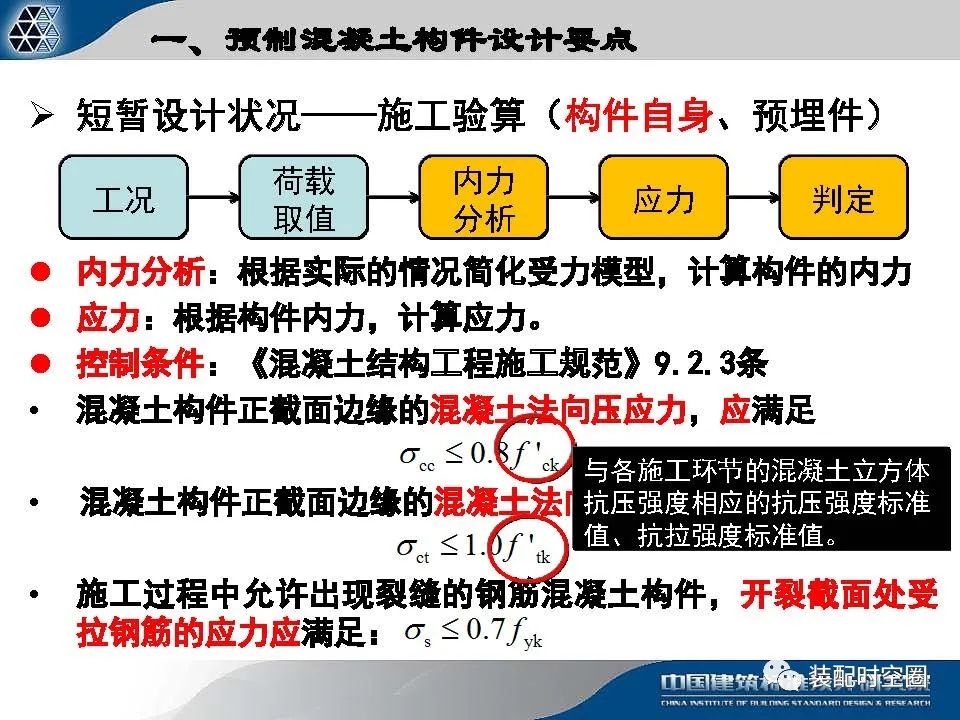

● internal force analysis: simplify the stress model according to the actual situation to calculate the internal force of the component.

● stress: calculate the stress according to the internal force of the member.

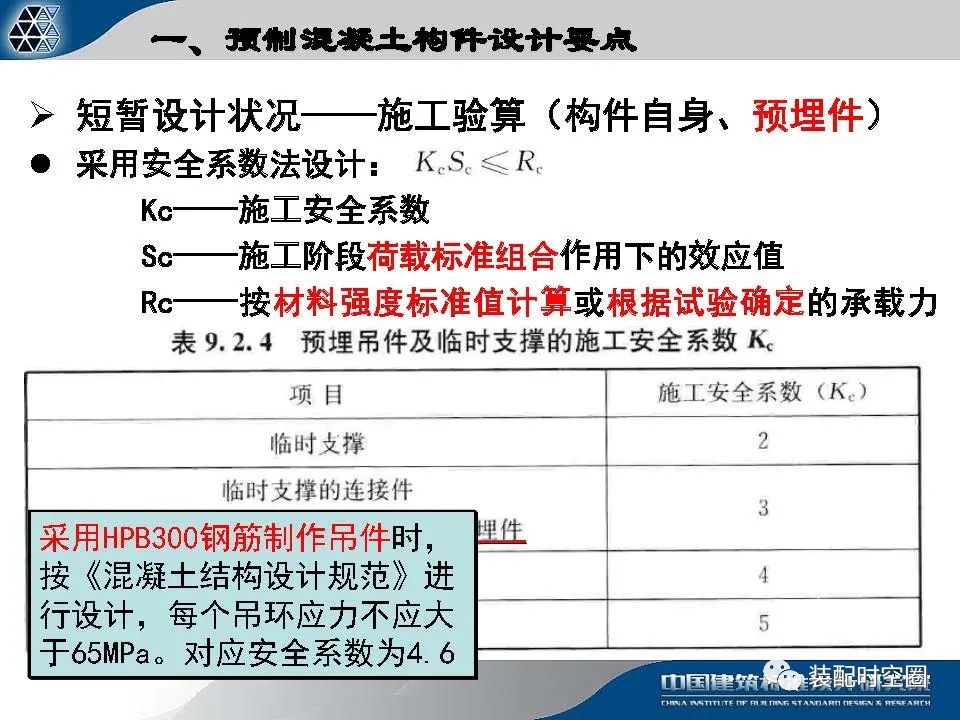

● control conditions: when hpb300 reinforcement is used to make lifting parts in article 9.2.3 of code for construction of concrete structures, it shall be designed according to code for design of concrete structures, and the stress of each lifting ring shall not be greater than 65mpa.

The corresponding safety factor is 4.6.

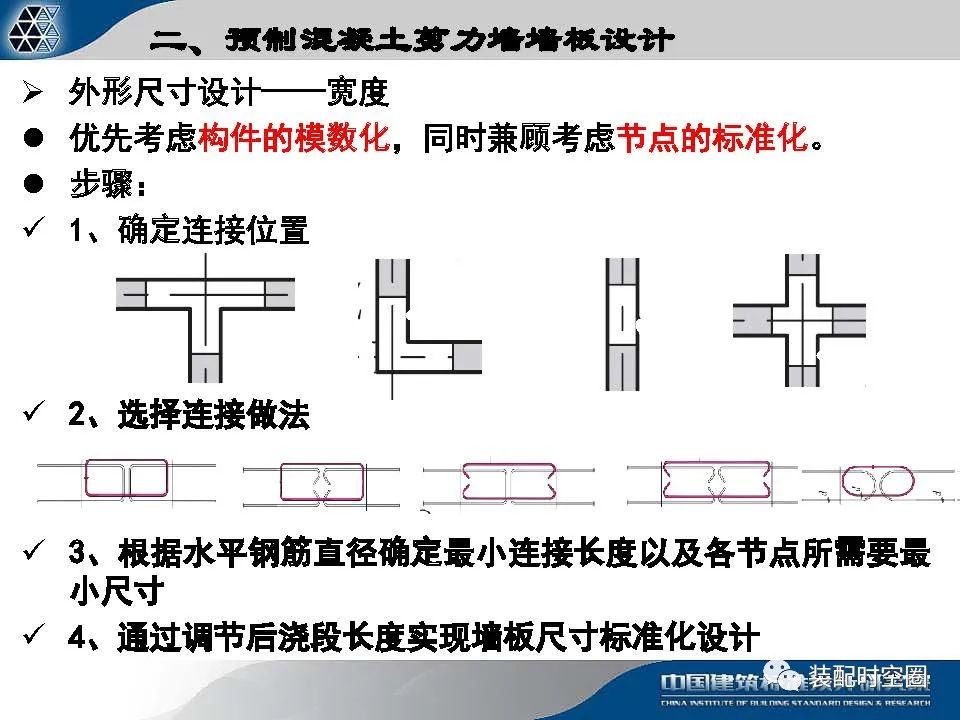

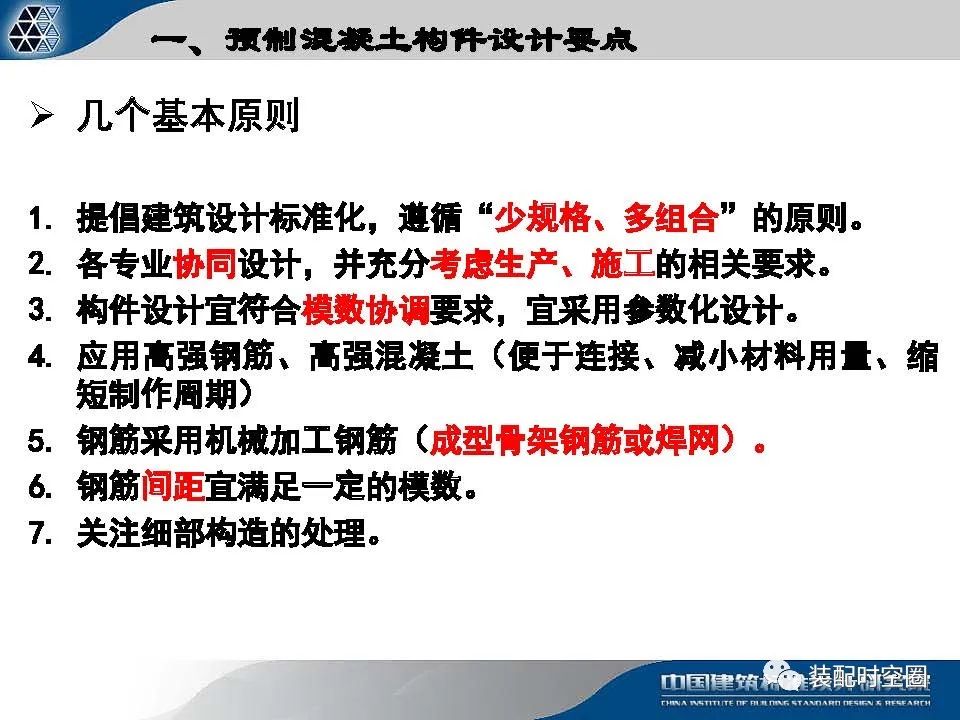

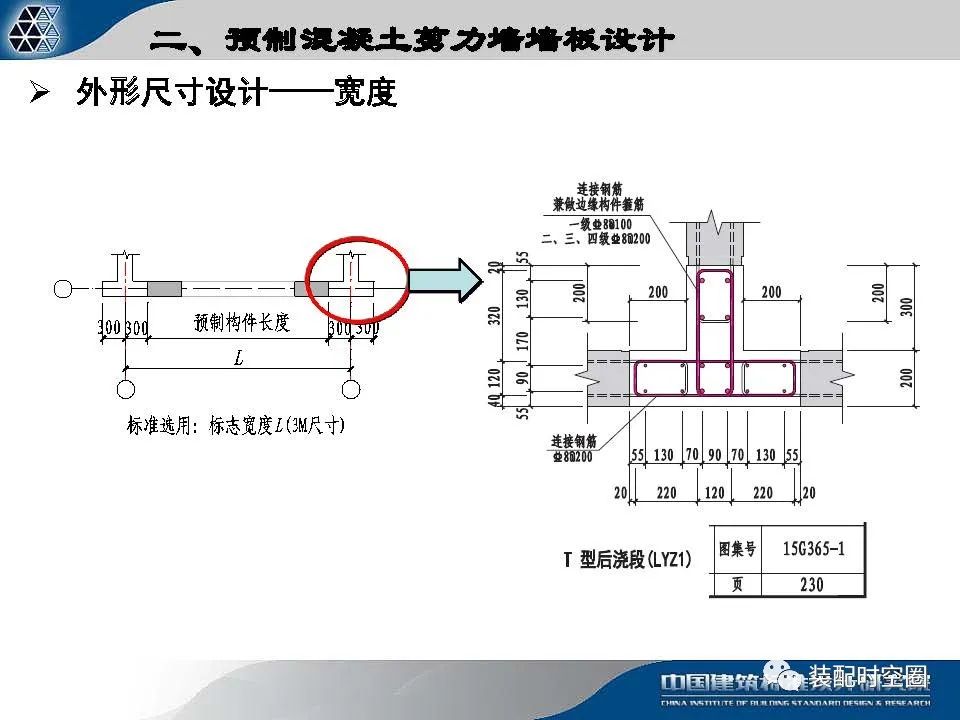

Basic principle: 1 Advocate architectural design standardization and follow the principle of “less specifications and more combinations”.

2.

All disciplines shall cooperate in the design, and fully consider the relevant requirements of production and construction.

3.

The component design should meet the requirements of module coordination and adopt parametric design.

4.

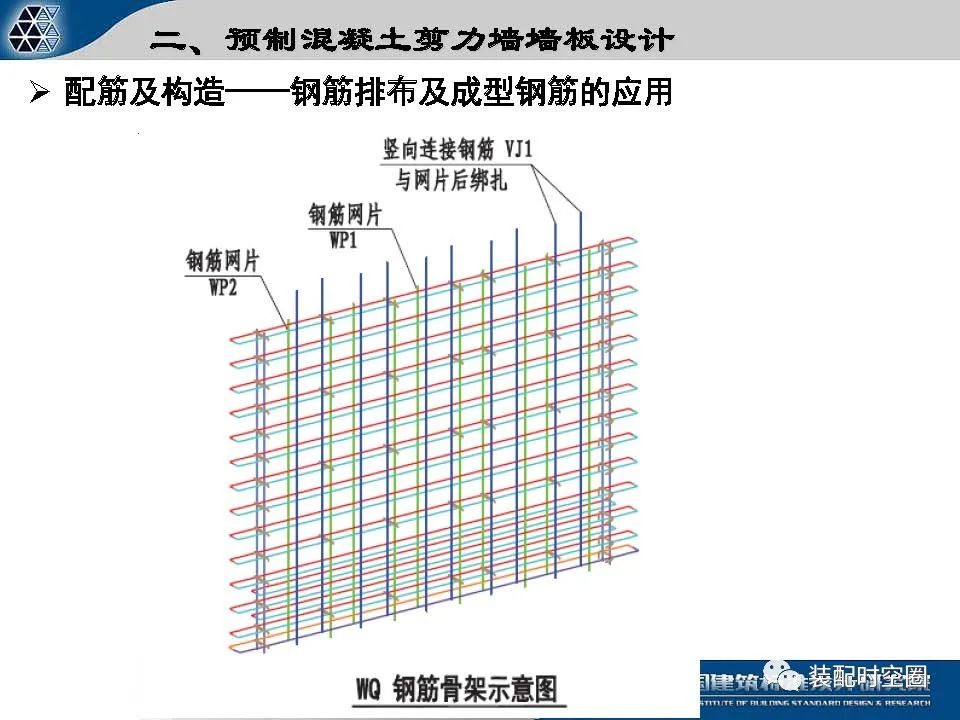

Apply high-strength reinforcement and high-strength concrete (facilitate connection, reduce material consumption and shorten production cycle).

5.

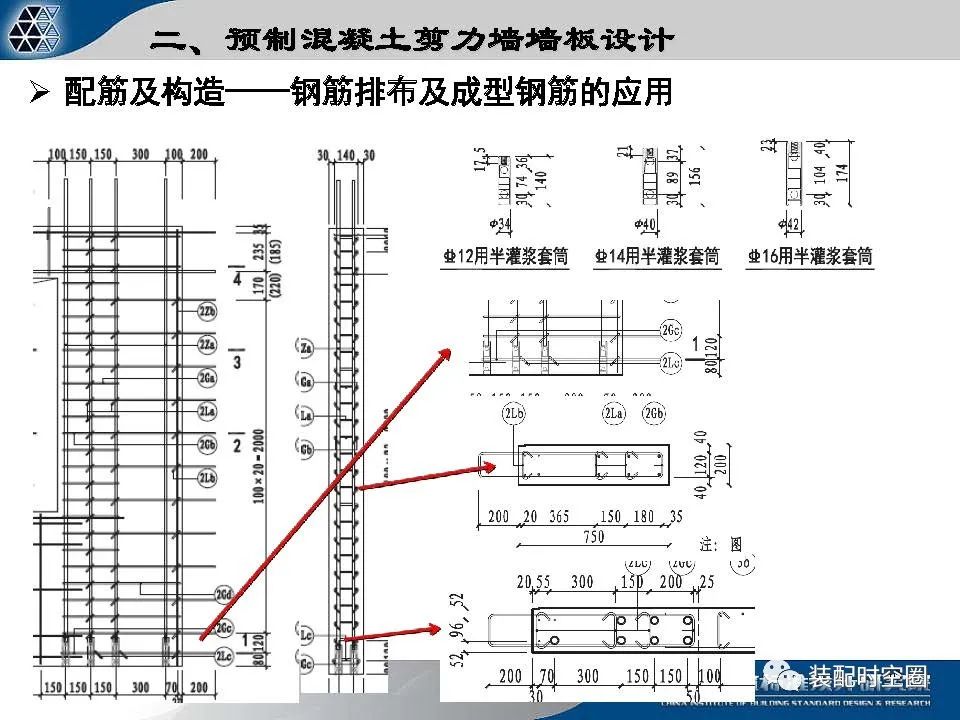

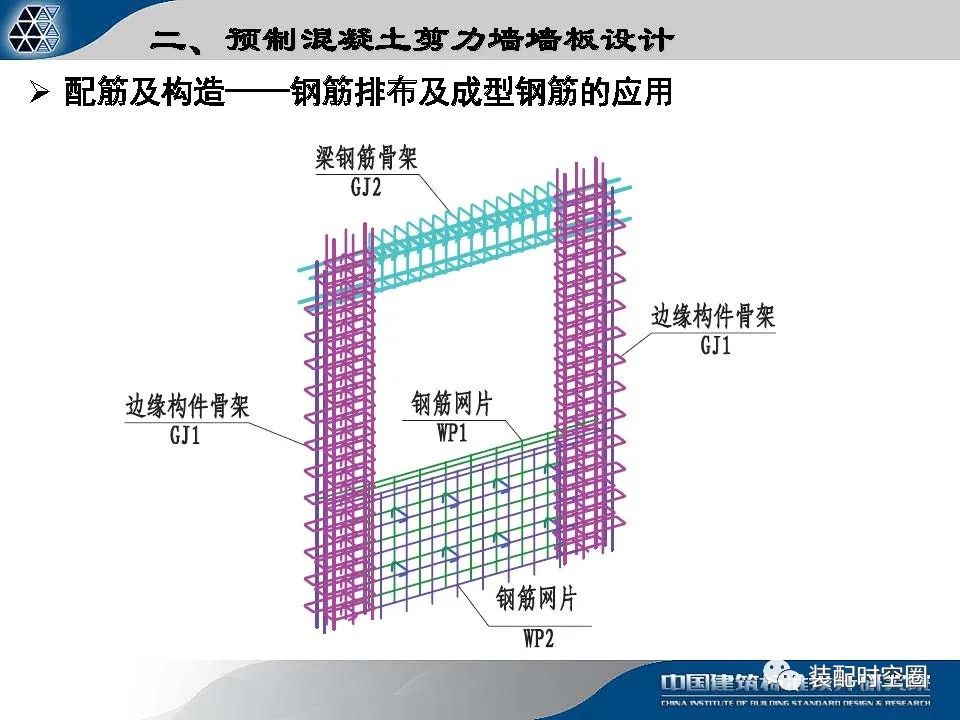

The reinforcement shall be machined reinforcement (formed skeleton reinforcement or welded mesh).

6.

The spacing of reinforcement should meet a certain modulus.

7.

Pay attention to the treatment of detail structure.

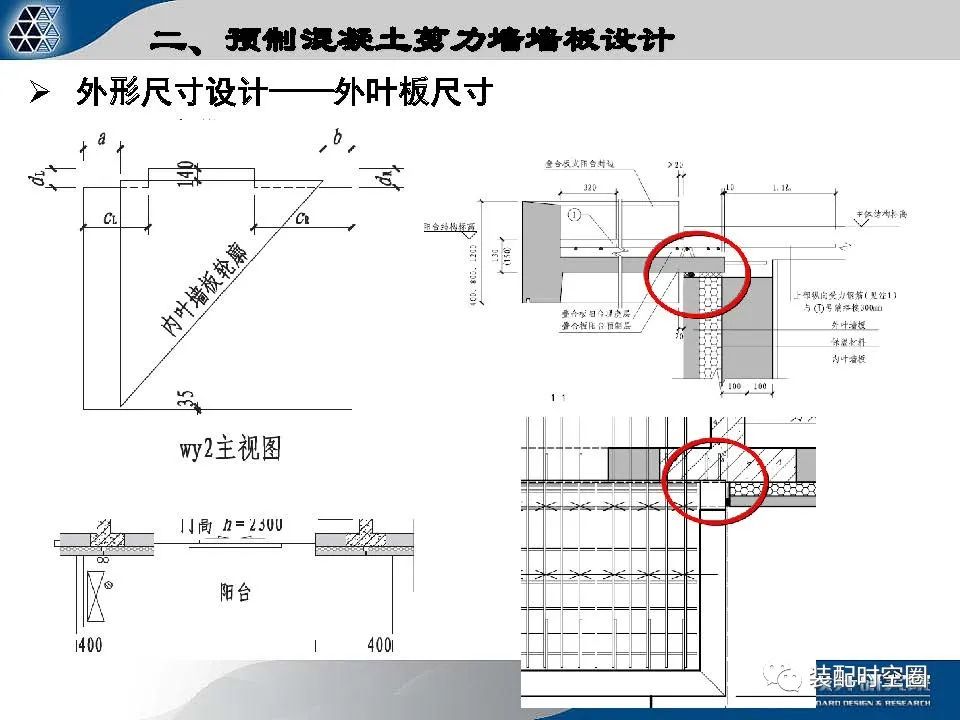

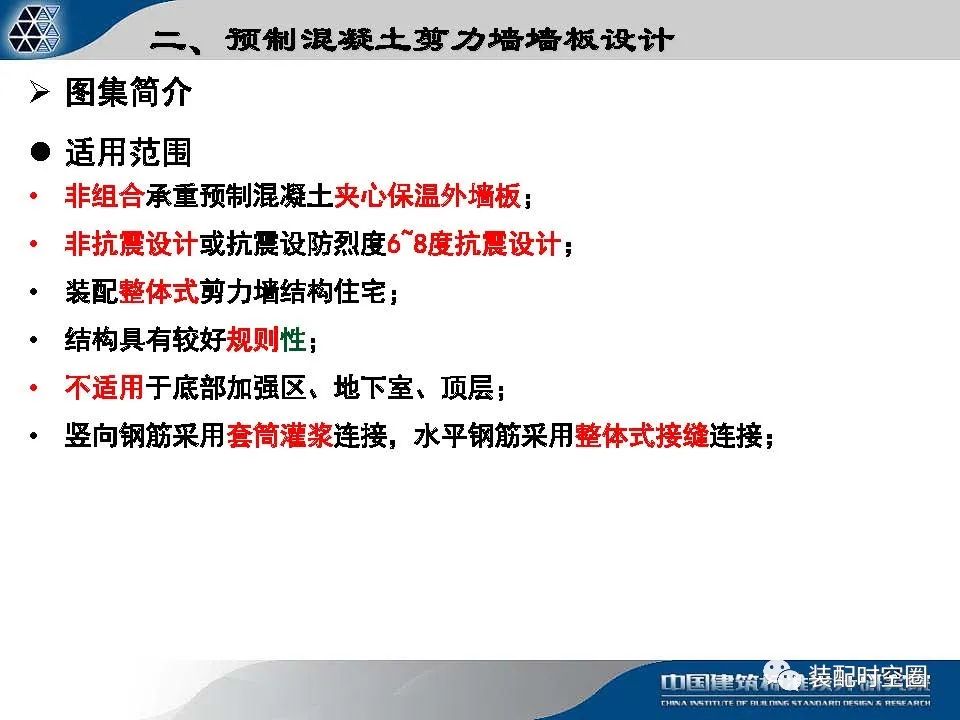

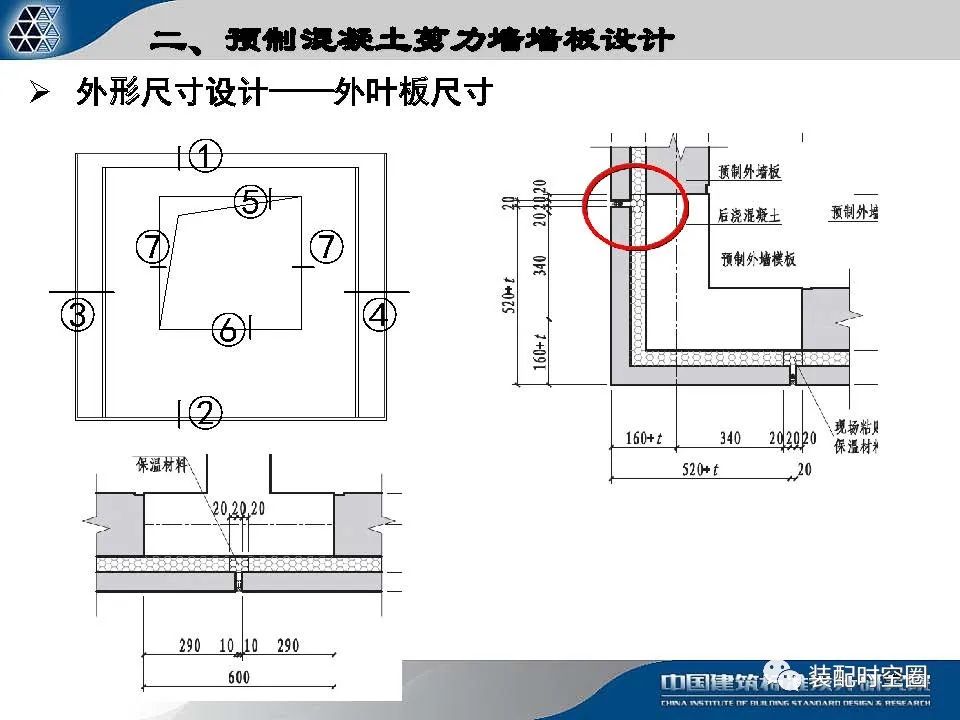

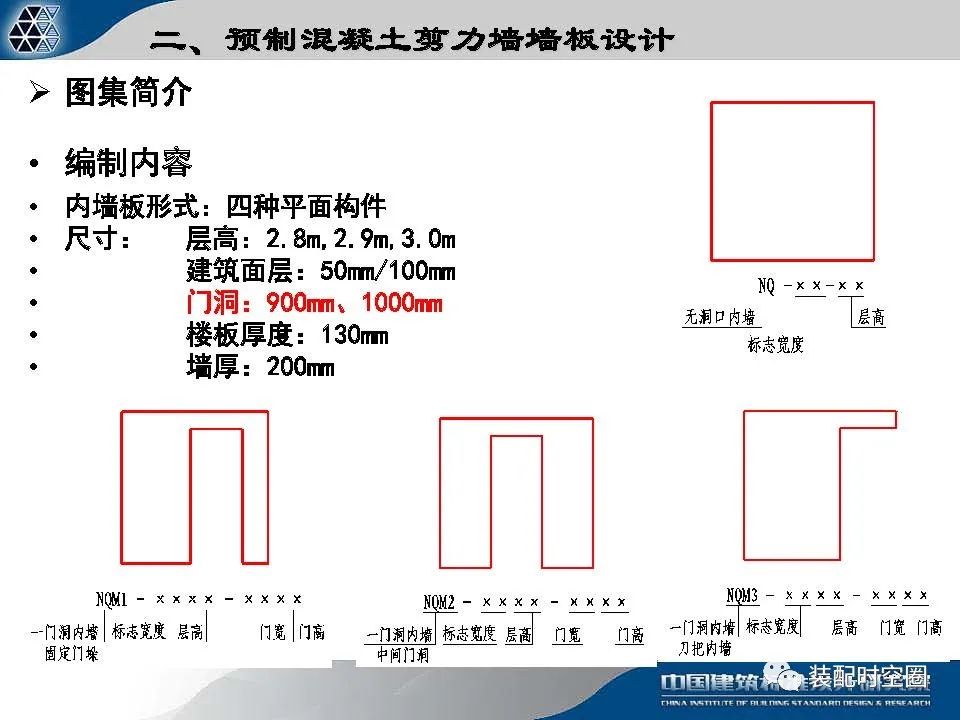

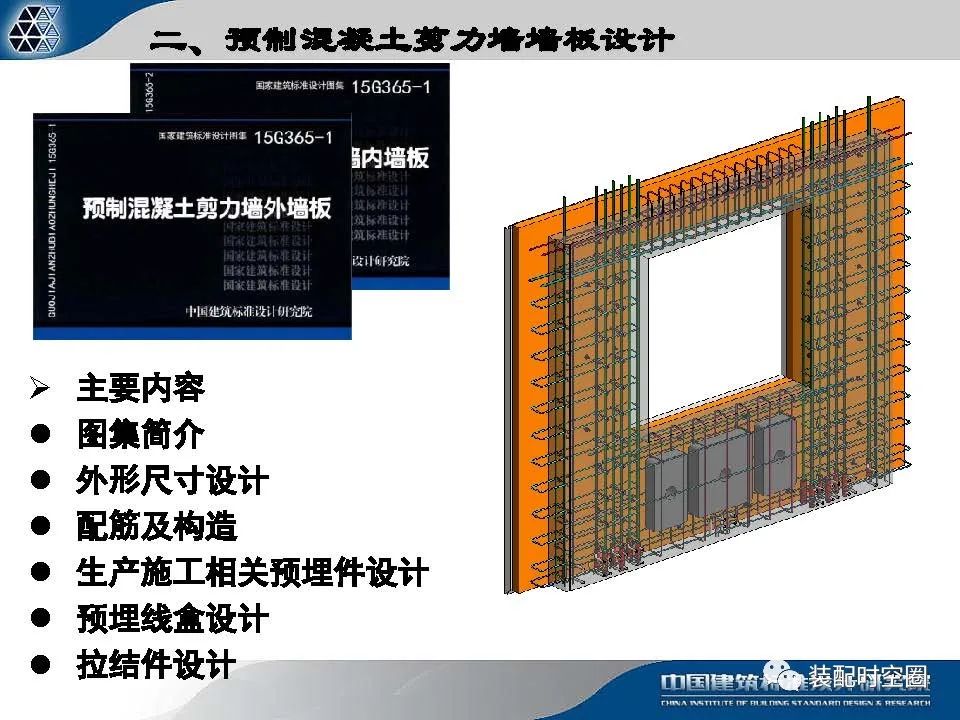

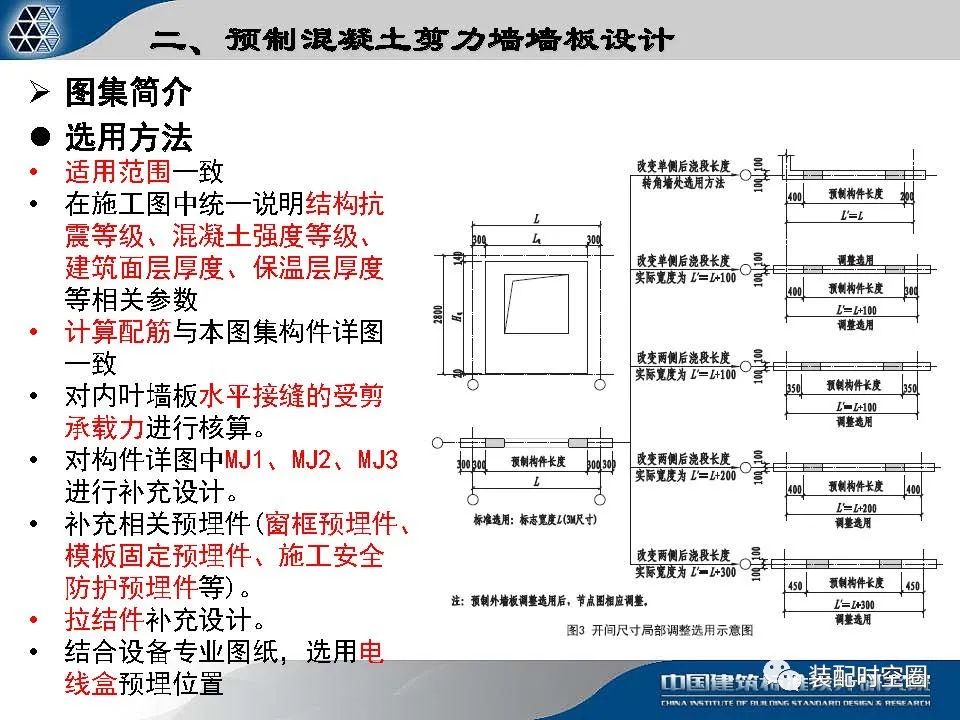

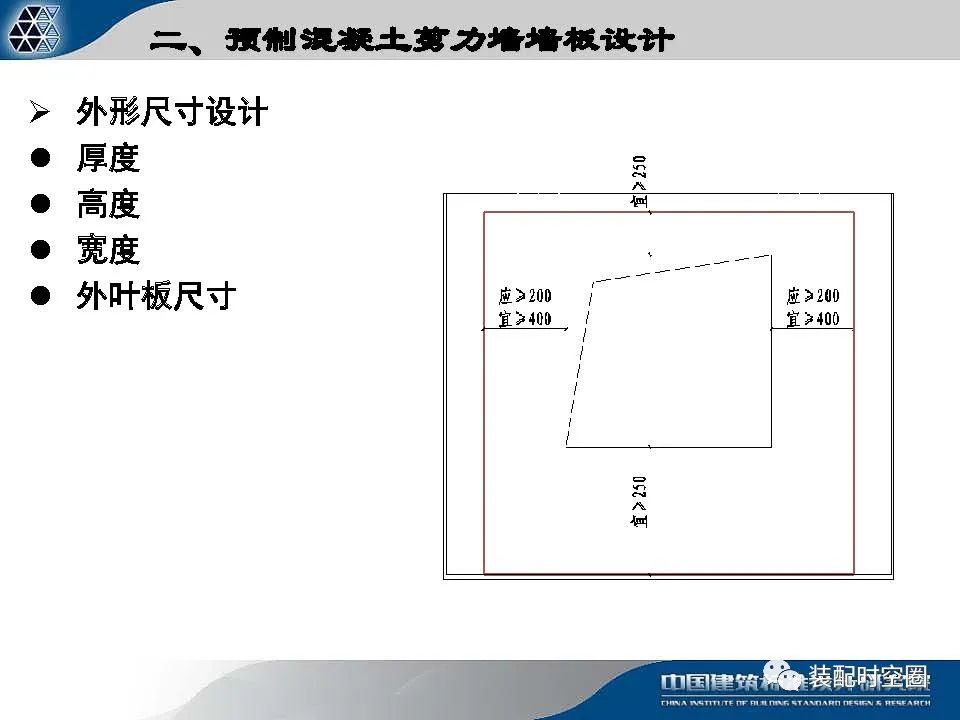

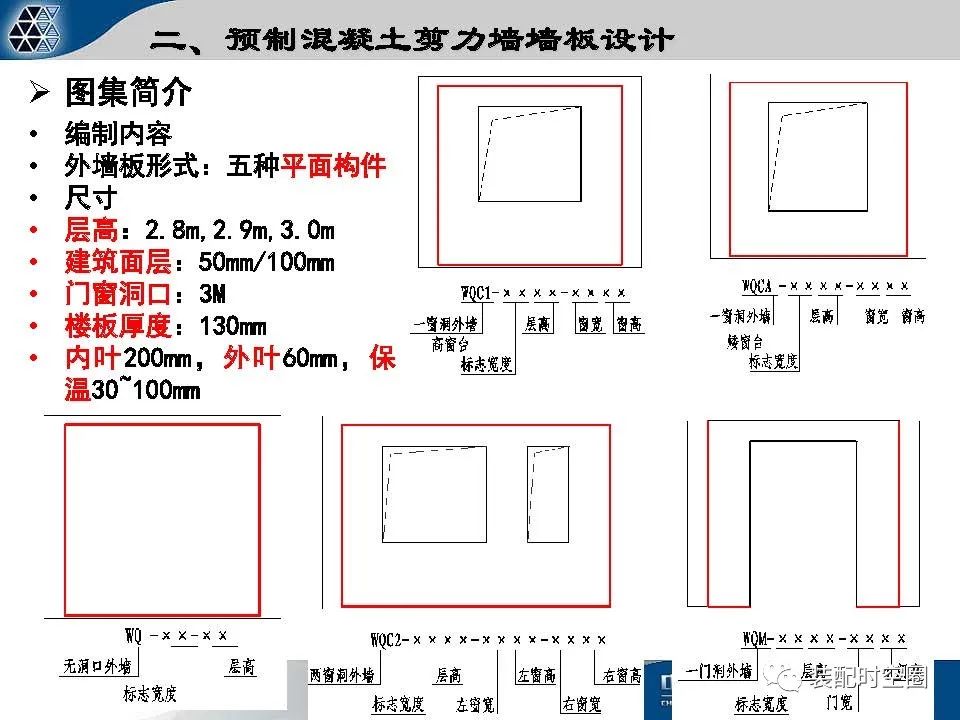

● scope of application of atlas: 1 Non combined load-bearing precast concrete sandwich thermal insulation exterior wall panel; 2.

Non seismic design or seismic design with seismic fortification intensity of 6-8; 3.

Houses with integral shear wall structure; 4.

The structure has good regularity; 5.

Not applicable to bottom reinforcement area, basement and top floor; 6.

The vertical reinforcement is connected by sleeve grouting, and the horizontal reinforcement is connected by integral joints.

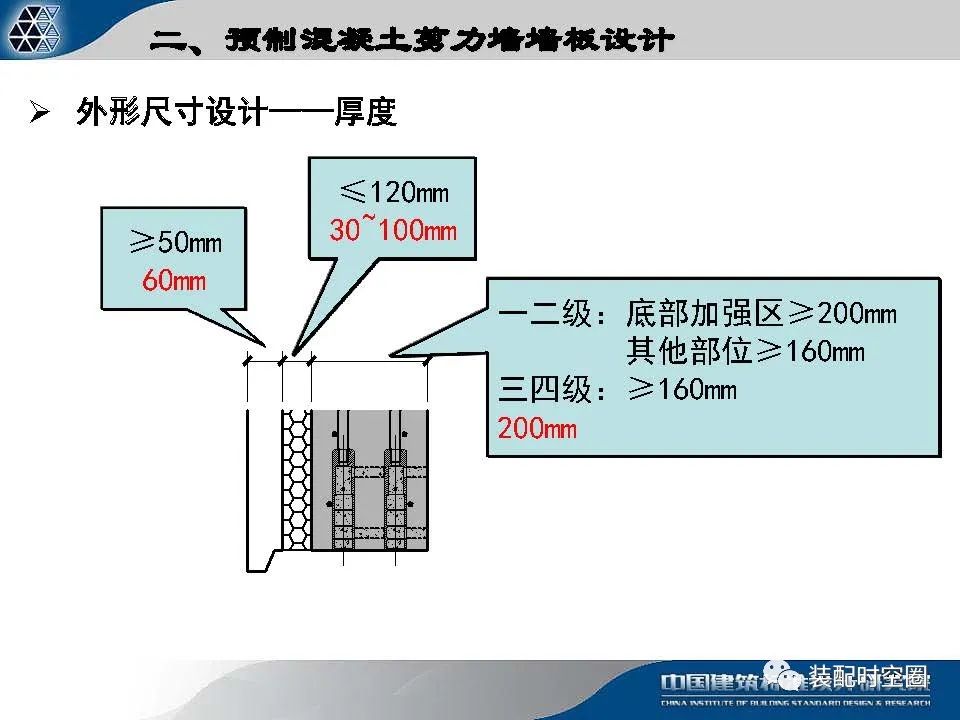

Principle: 1 The safety grade of precast exterior wall panels is grade II, and the design service life is 50 years.

2.

The exterior wall panel is designed according to class II a environment category, and the interior wall panel is designed according to class I environment category.

3.

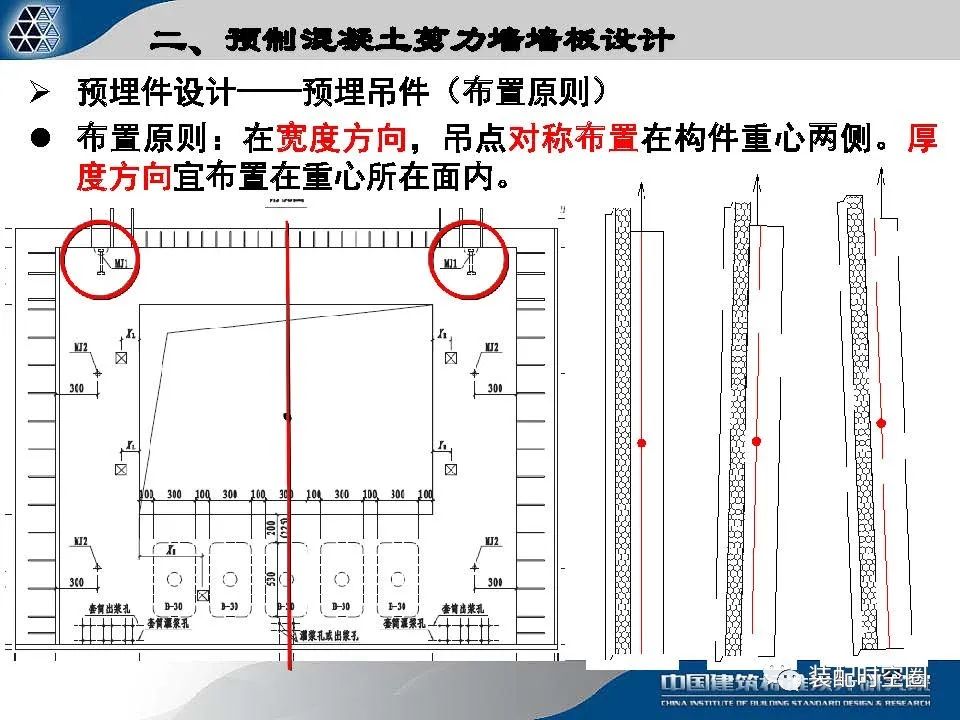

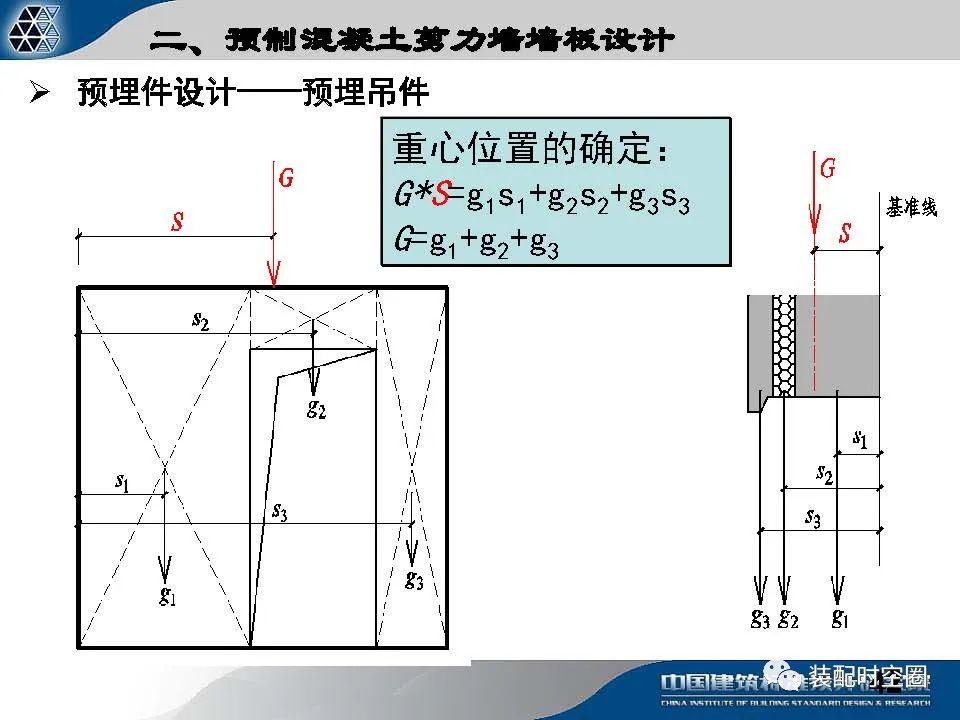

The position of embedded lifting parts shall be given, and the dead weight of wallboard shall be given.

The specification and corresponding structure of lifting parts shall be supplemented.

4.

The specification and structure of embedded parts shall be selected by ourselves for the given position of MJ2 of temporary support embedded parts.

5.

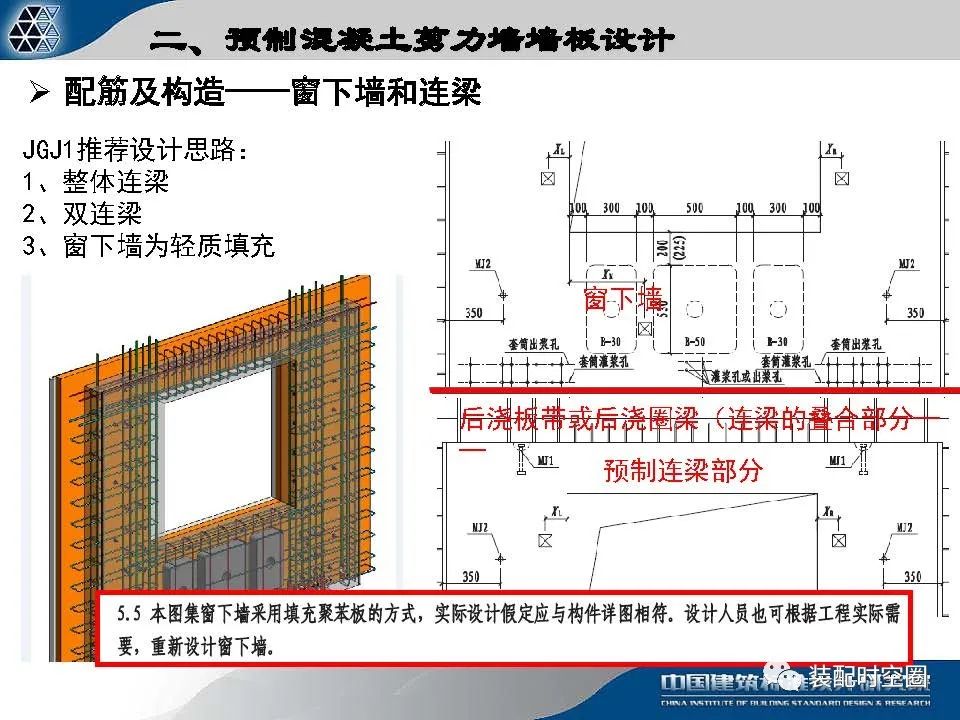

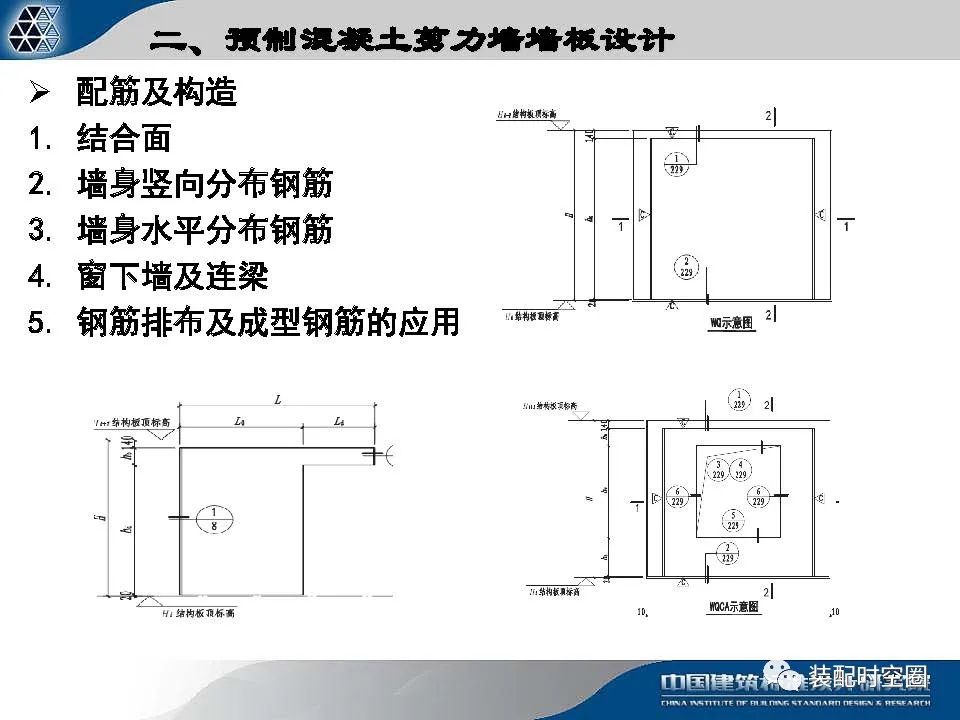

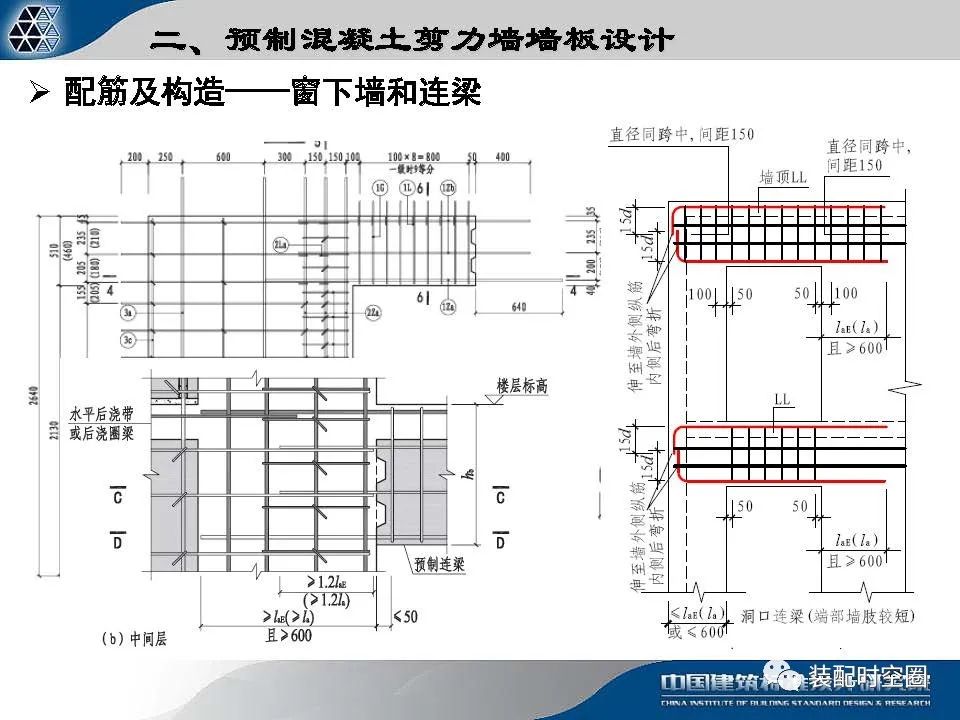

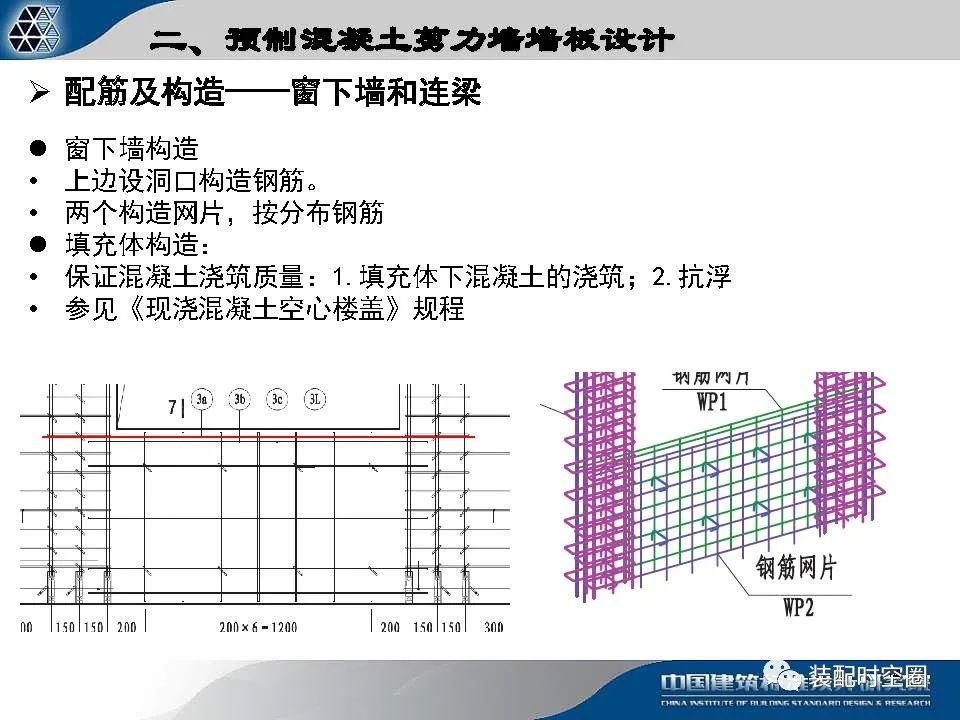

The wall under the window is filled with polystyrene board, and the actual design assumption shall be consistent with the component details.

6.

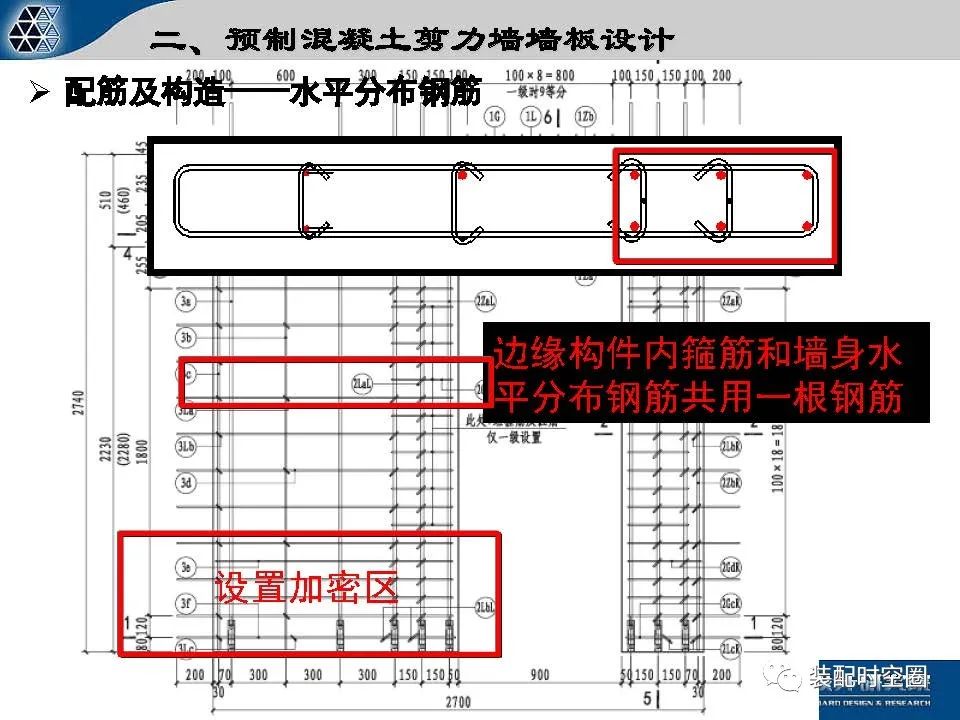

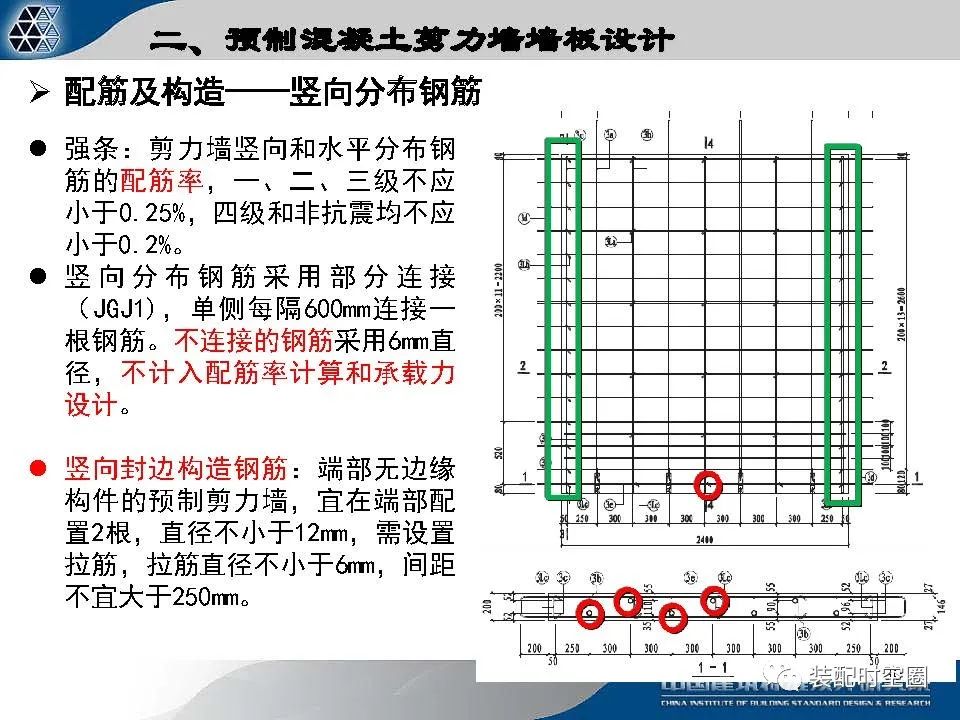

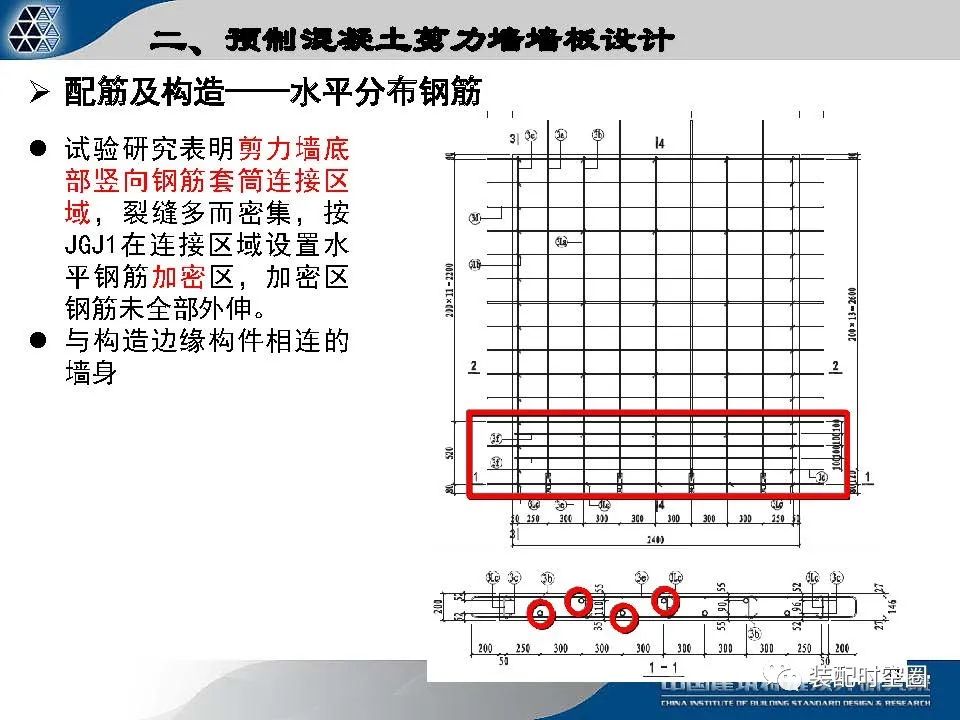

The reinforcement of wallboard (including wall body reinforcement, edge member reinforcement and coupling beam reinforcement) shall be designed according to the minimum reinforcement ratio.

7.

The precast exterior wall panel components are not shown in the drawing, and shall be designed separately.

8.

The grouting sleeve for connecting reinforcement in the component detail drawing shall be prepared according to the fixed size.

Before reinforcement processing, the processing length of connecting reinforcement shall be rechecked and adjusted according to the specification and size of the actually used grouting sleeve.

9.

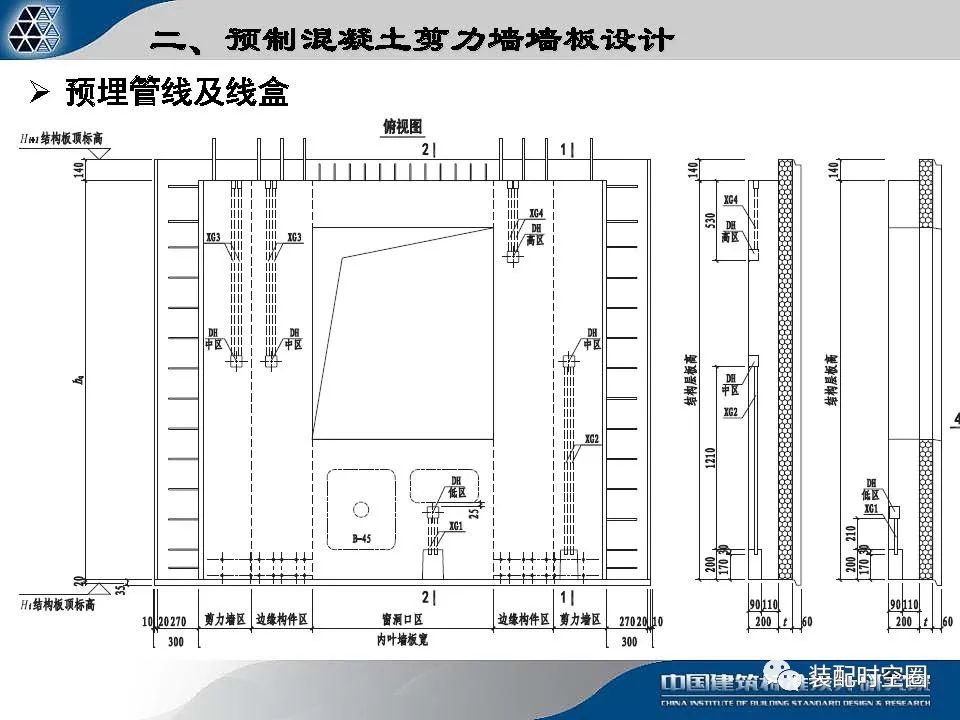

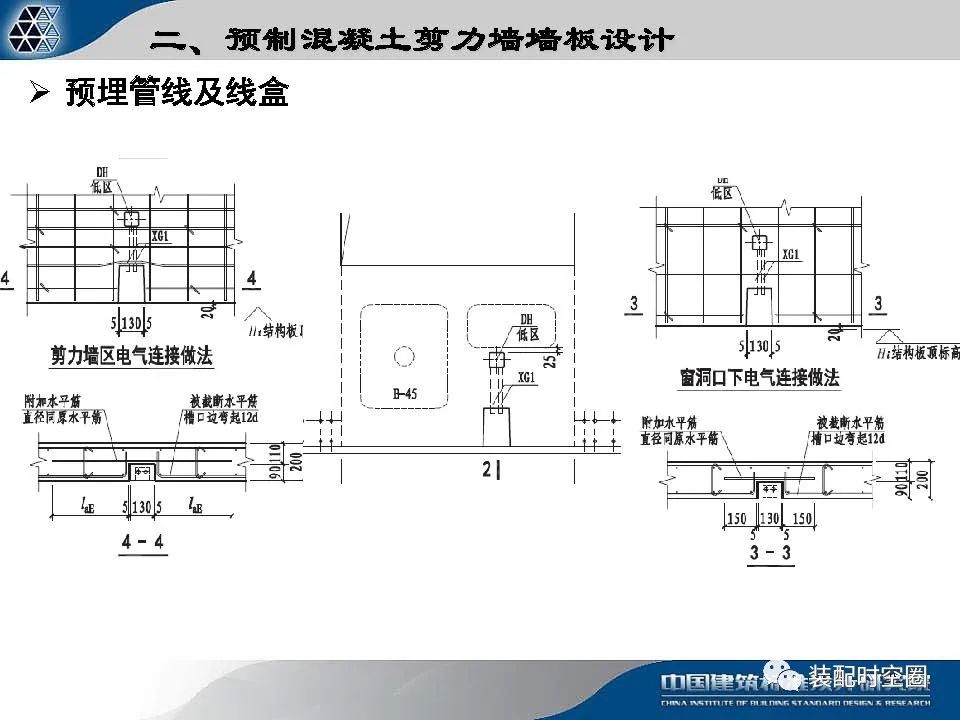

The position of embedded wire box is recommended in the template drawing, which can be selected by the designer according to needs…